Method for preparing rutile-type titanium dioxide

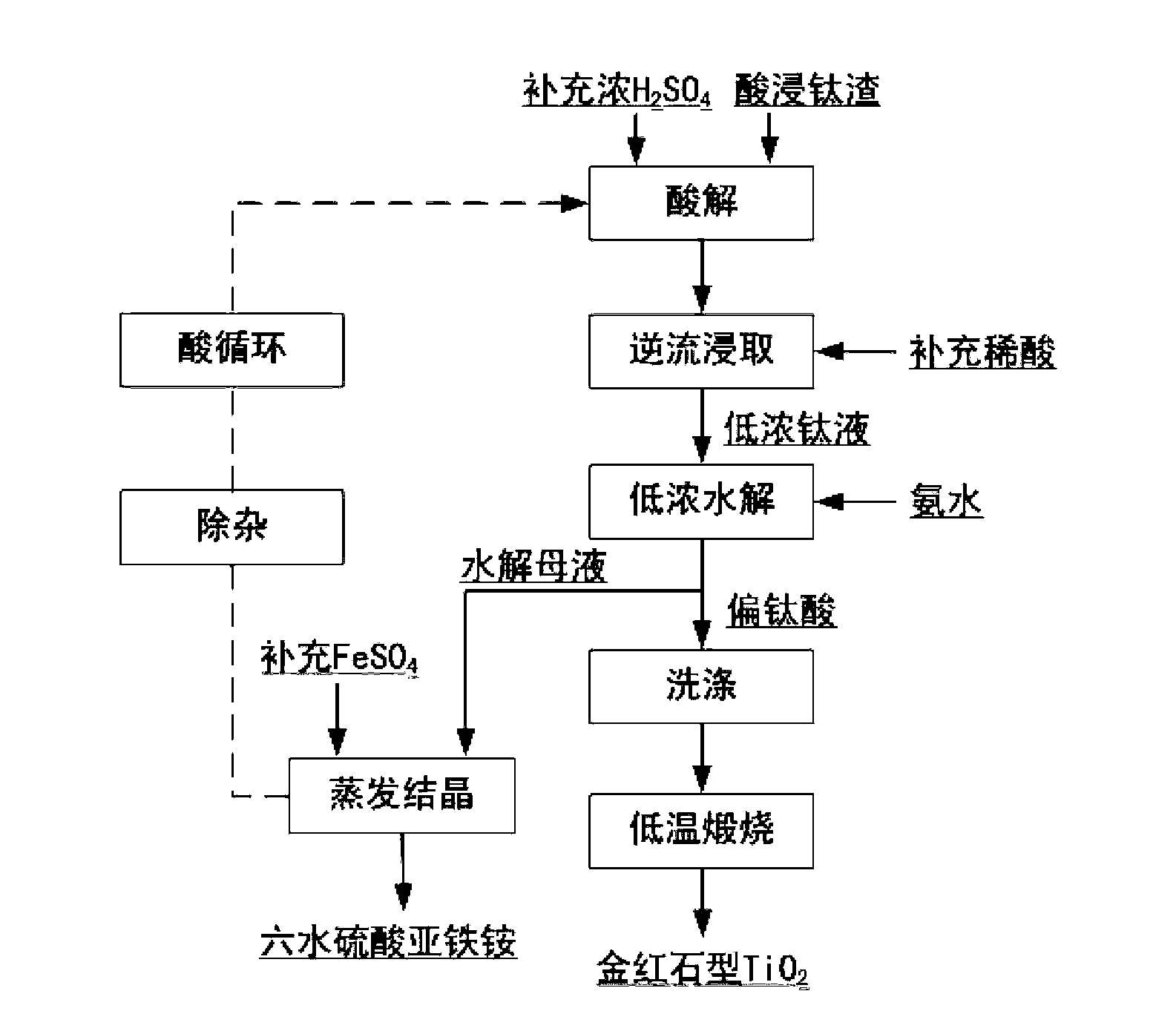

A titanium dioxide and rutile-type technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve problems such as complex process flow, achieve simple process flow, simplify process flow, and reduce raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

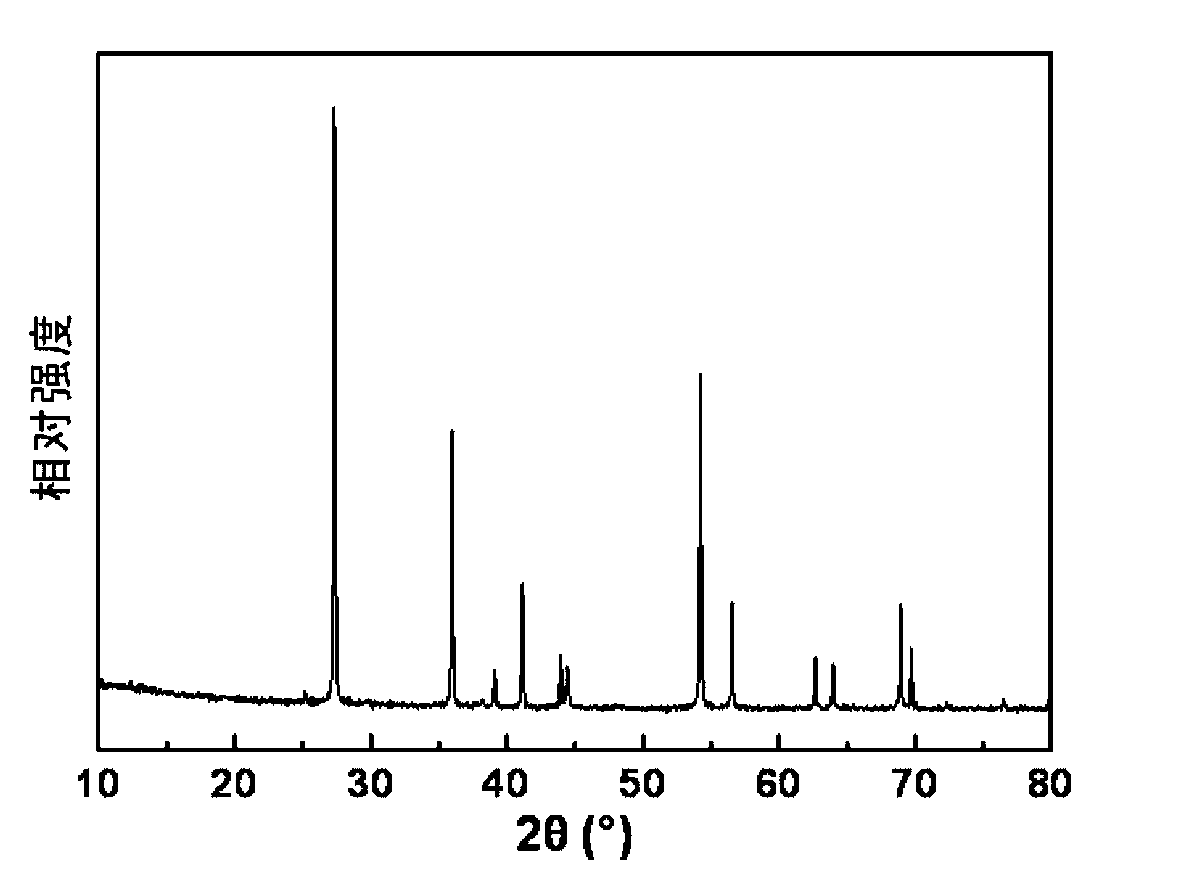

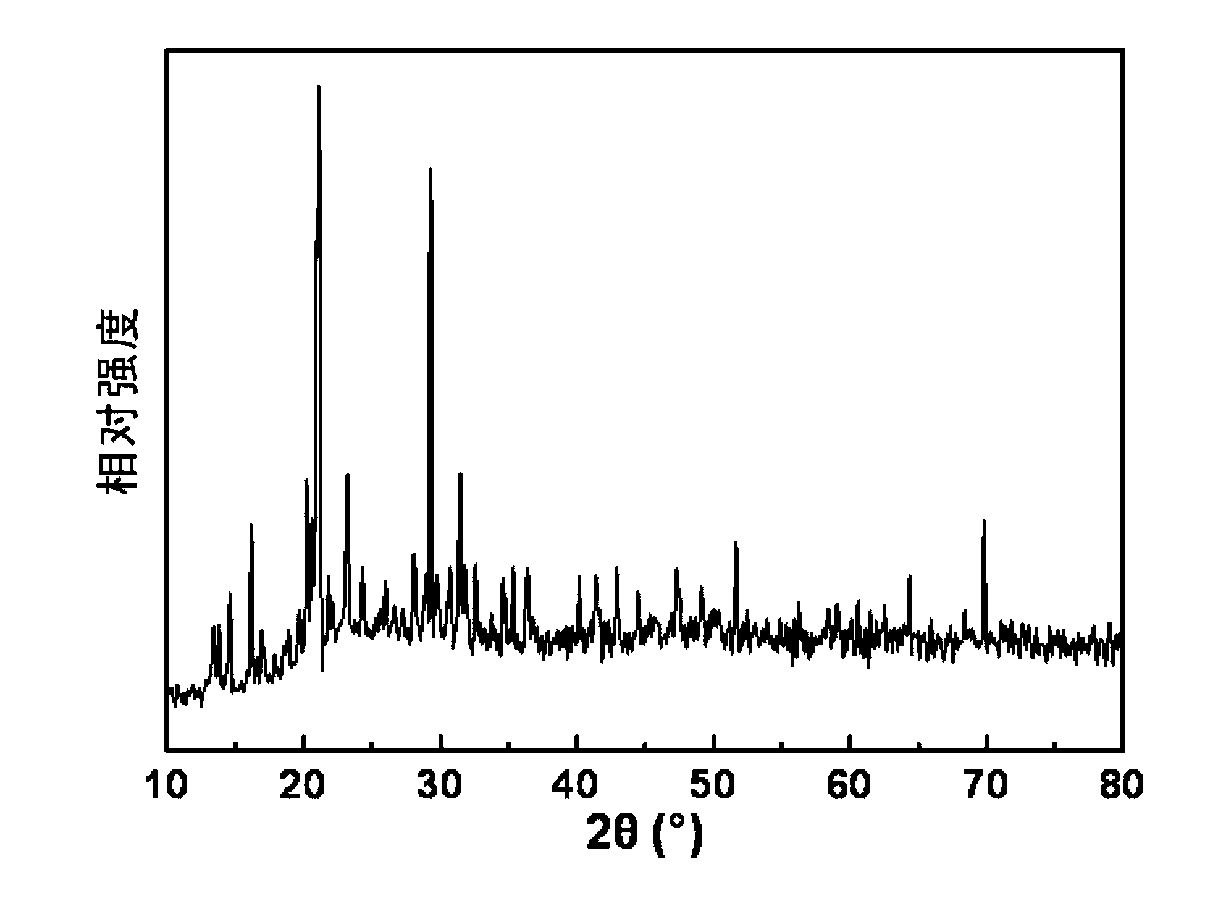

Embodiment 1

[0032] The titanium slag (TiO 2 The mass content is 49.0%), mixed evenly under stirring, and reacted at 150°C for 2.5h, wherein, the solid-liquid mass ratio of acid-leached titanium slag and sulfuric acid was 1.5:1, and the intermediate product obtained after the reaction was mixed with 5% The dilute sulfuric acid for three-stage countercurrent leaching, wherein the mass ratio of the intermediate product to dilute sulfuric acid for leaching is 1:1.2. After filtering, add the ammoniacal liquor that mass percentage concentration is 25% in gained filtrate, wherein ammoniacal liquor addition is 22% of filtrate volume, then add trivalent titanium solution as reductant, make ferric iron all be reduced to ferrous iron, obtain TiO 2 The concentration is 108g / L titanium liquid, and finally hydrolysis is carried out at 120°C for 3 hours, and the hydrolyzed product is filtered to obtain a white hydrated titanium dioxide solid, which is calcined at 850°C for 2 hours to obtain rutile tita...

Embodiment 2

[0034] The titanium slag (TiO 2 The mass content is 52.4%), mixed evenly under stirring, and reacted at 200°C for 0.5h. The dilute sulfuric acid for three-stage countercurrent leaching, wherein the mass ratio of the intermediate product to dilute sulfuric acid for leaching is 1:1.5. After filtering, add 25% ammonia water to the obtained filtrate, wherein the amount of ammonia water added is 12% of the volume of the filtrate, and then add iron powder as a reducing agent to reduce all ferric iron to ferrous iron to obtain TiO 2The concentration is 120g / L titanium liquid, and finally hydrolysis is carried out at 115°C for 3.5 hours, and the hydrolyzed product is filtered to obtain a white hydrated titanium dioxide solid, which is calcined at 900°C for 2 hours to obtain rutile titanium dioxide; the hydrolyzed mother liquor is slowly heated at 85°C for 4 Hour, wherein, the solid-liquid mass ratio of vitriol and hydrolysis mother liquor is 1:35, obtains light green ferrous ammonium...

Embodiment 3

[0036] The sulfuric acid solution obtained in Example 2 (mass percentage concentration is 85%) is circulated back to the sulfuric acid solution of the reactor and the titanium slag (TiO 2 The mass content is 49.8%), mixed evenly under stirring, and reacted at 180°C for 1h, wherein the solid-liquid mass ratio of acid-leached titanium slag and sulfuric acid was 1.3:1, and the intermediate product obtained after the reaction was mixed with 20% Dilute sulfuric acid is used for three-stage countercurrent leaching, wherein the mass ratio of intermediate product to dilute sulfuric acid for leaching is 1:0.8. After filtering, add 28% ammoniacal liquor to the obtained filtrate, wherein the amount of ammoniacal liquor added is 7% of the volume of the filtrate, and then add sodium sulfite as a reducing agent to completely reduce ferric iron to ferrous iron to obtain TiO 2 The concentration is 125g / L titanium liquid, and finally hydrolysis is carried out at 80°C for 8 hours, and the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com