Electric adsorption device of sheathed electrode

A coated electrode and electro-adsorption technology, applied in the separation method, dispersed particle separation, etc., can solve problems such as increasing interface resistance, hindering ion migration, and affecting adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

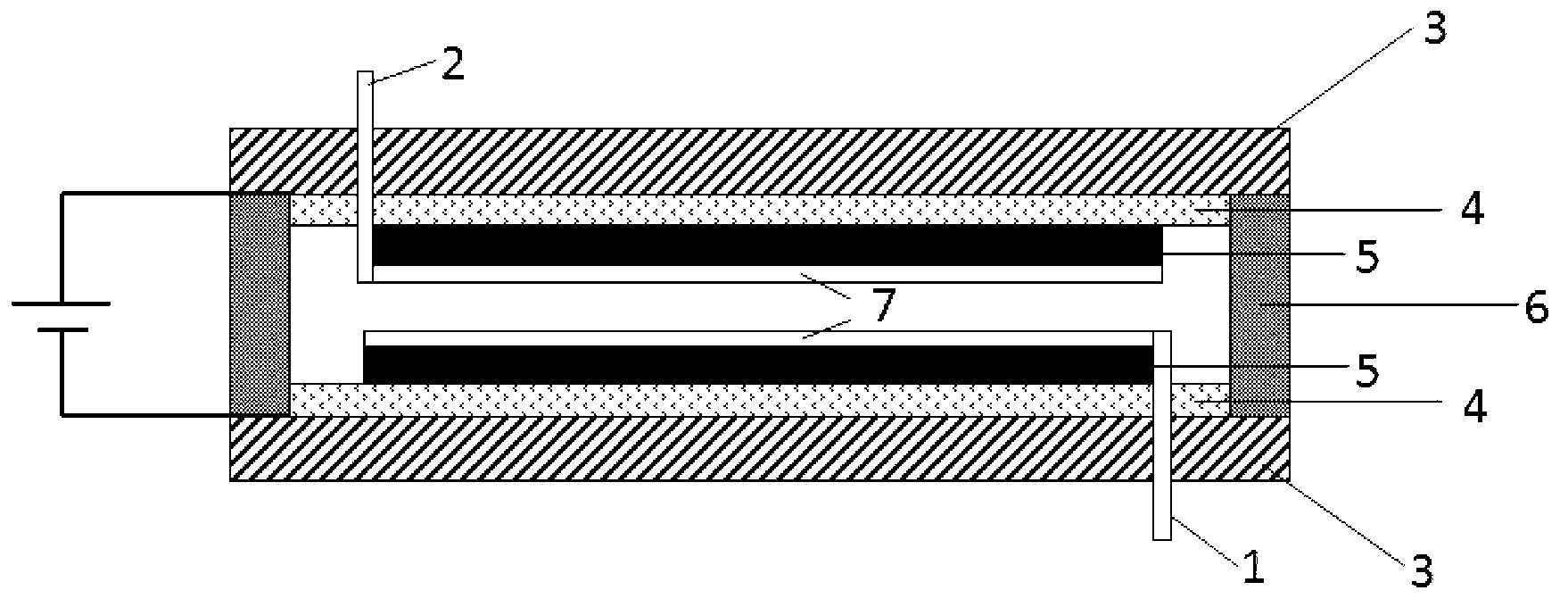

Method used

Image

Examples

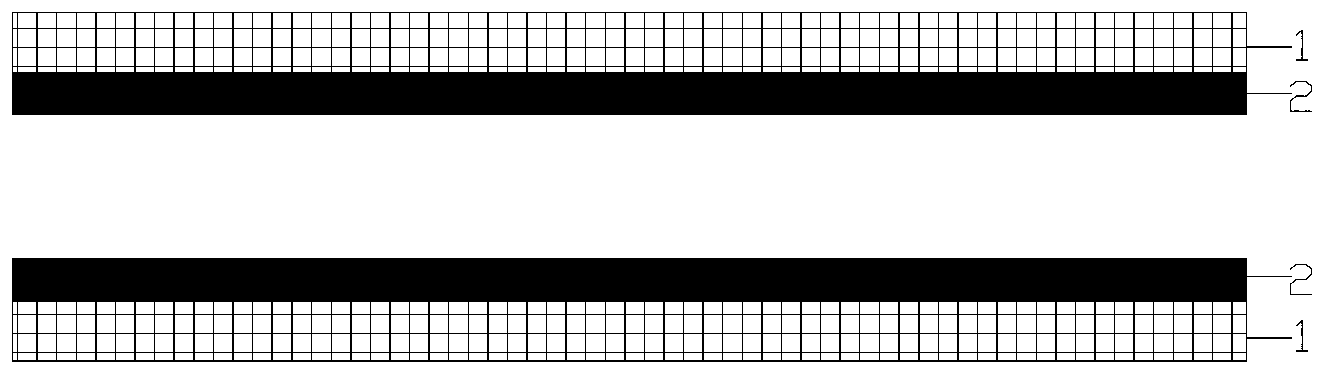

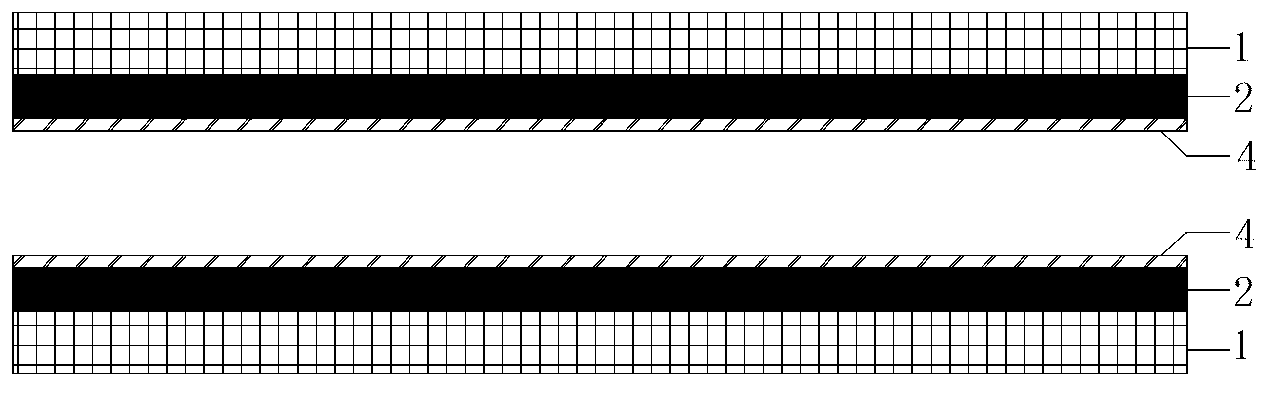

example 1

[0023] Use activated carbon as the electro-adsorption material, mix activated carbon, carbon black and 60% polytetrafluoroethylene solution according to the mass ratio of 75%, 15%, and 10%, and then add ethanol to make it into a plasticine shape and then heat it at 10MPa It is pressed on the foamed nickel under the pressure to make the electrode sheet. Then the perfluorosulfonic acid resin solution was diluted into a uniform solution according to the ratio of 5g resin solution and 1mL N,N dimethylformamide. Then coat it on the cathode electrode sheet and control the thickness to 100 μm. Put the cathode electrode sheet in an oven and dry it at 80°C for 1 hour, then raise the temperature to 160°C. After 20 minutes, raise the temperature to 180°C. After 10 minutes, close the oven and let the electrode sheet cool down naturally. In this way, an electrode sheet with a cation exchange coating is obtained, which is assembled into an electro-absorption device, and the electro-absorpti...

example 2

[0026] Use activated carbon as the electro-adsorption material, mix activated carbon, carbon black and 60% polytetrafluoroethylene solution according to the mass ratio of 75%, 15%, and 10%, and then add ethanol to make it into a plasticine shape and then heat it at 10MPa It is pressed on the foamed nickel under the pressure to make the electrode sheet. Then the perfluorosulfonic acid resin solution was diluted into a uniform solution according to the ratio of 5g resin solution and 1mL N,N dimethylformamide. Then coat it on the cathode electrode sheet and control the thickness to 1 μm. Put the cathode electrode sheet in an oven and dry it at 80°C for 1 hour, then raise the temperature to 160°C. After 20 minutes, raise the temperature to 180°C. After 10 minutes, close the oven and let the electrode sheet cool down naturally. In this way, an electrode sheet with a cation exchange coating is obtained, which is assembled into an electro-absorption device, and the electro-absorption...

example 3

[0029] Use activated carbon as the electro-adsorption material, mix activated carbon, carbon black and 60% polytetrafluoroethylene solution according to the mass ratio of 75%, 15%, and 10%, and then add ethanol to make it into a plasticine shape and then heat it at 10MPa It is pressed on the foamed nickel under the pressure to make the electrode sheet. Using aluminum trichloride as a catalyst, chloroacetyl chloride is used to carry out the chloroacetylation reaction of polyphenylene ether. The obtained chloroacetylated polyphenylene ether was dissolved in N,N dimethylformamide to make a casting solution with a concentration of 20%, and then it was coated on the anode electrode sheet and the thickness was controlled to 20μm. The electrode sheet is placed in an oven and dried at 60°C to solidify the electrode surface. After the electrode sheet is safely dried, it is immersed in a 30% trimethylamine solution and reacted for 24 hours to obtain an electrode sheet with anion exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com