Composite blast furnace mineral powder and synthetic material made from same

A technology of blast furnace slag powder and composite powder, which is applied in the field of composite materials, can solve problems such as limitations in the application field of blast furnace slag powder, and achieve the effects of saving energy and reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

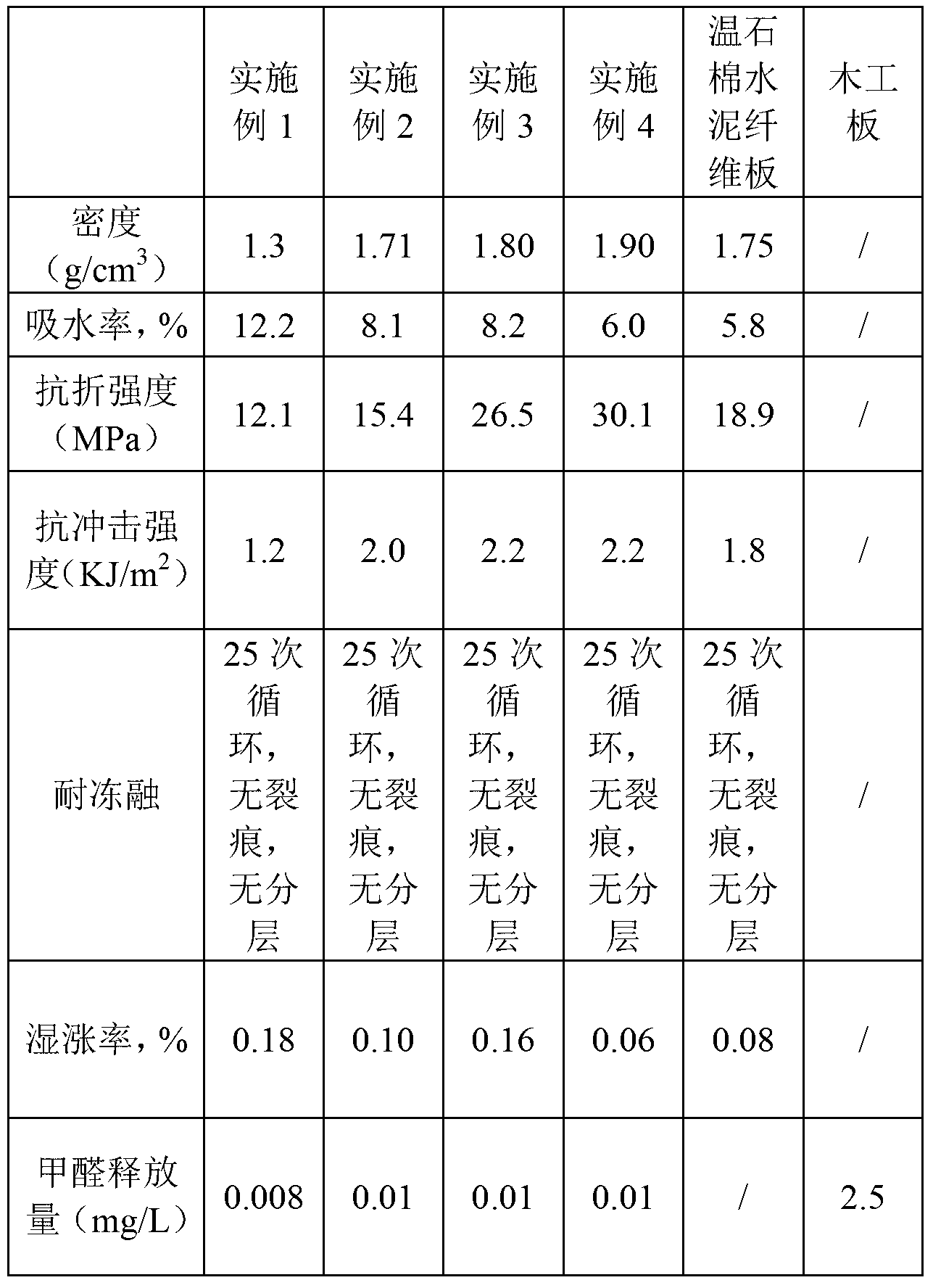

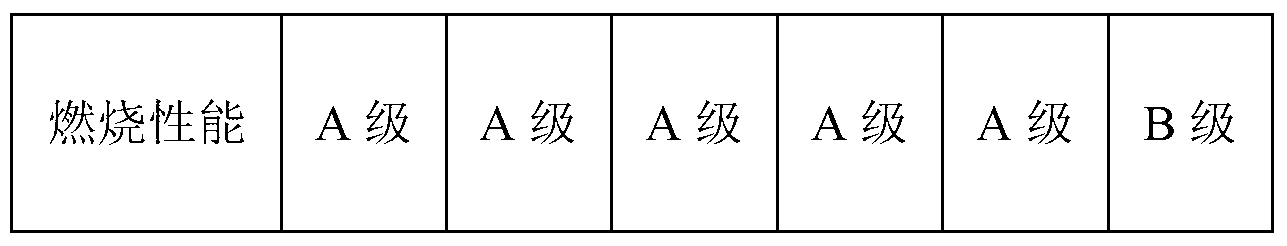

Examples

Embodiment 1

[0025] A blast furnace slag composite powder, its raw materials are composed of the following mass percentage components: blast furnace slag 45%, acrylic acid polymer emulsion (M-8504 of Guangzhou Mirungao Chemical Co., Ltd., solid content 48%) 7%, high strength High modulus polyvinyl alcohol fiber (Anhui Wanwei Group) 0.5%, the balance is quartz sand.

[0026] The preparation method of above-mentioned blast furnace slag composite powder comprises the following steps:

[0027] 1) Add 12% water of the total weight of raw materials to the acrylic polymer emulsion, stir evenly to obtain a polymer suspension;

[0028] 2) After pulverizing the quartz sand, mix it with the remaining raw materials, then add it to the polymer suspension, stir it into a uniform paste, let it stand for 2 hours, and dehydrate it until the water content is 8%, so as to obtain the blast furnace slag composite powder.

[0029] The above-mentioned dry powder is pressed into a plate by a 3,000-ton press, dri...

Embodiment 2

[0031] A blast furnace slag composite powder, the raw material is composed of the following mass percentage components: 48% of blast furnace slag, 9% of acrylic acid polymer emulsion (Zhongshan Sanjian Synthetic Materials Co., Ltd. 715, solid content 45%) 9%, high strength and high modulus polymer Vinyl alcohol fiber (Kuraray, Japan) 0.8%, the balance is stone powder.

[0032] The preparation method of above-mentioned blast furnace slag composite powder comprises the following steps:

[0033] 1) Add 12% water of the total weight of raw materials to the acrylic polymer emulsion, stir evenly to obtain a polymer suspension;

[0034] 2) After pulverizing the stone powder, mix it with the remaining raw materials, then add it to the polymer suspension, stir it into a uniform paste, let it stand for 2 hours, and dehydrate it until the water content is 10%.

[0035] Mineral powder composite powder.

[0036] The above-mentioned dry powder is pressed into a plate by a 6,000-ton press,...

Embodiment 3

[0038] A blast furnace slag composite powder, its raw materials are composed of the following mass percentage components: 50% of blast furnace slag, 11% of acrylic acid polymer emulsion (Zhejiang Xinli Chemical Co., Ltd. XL-100A, solid content 50%), high strength and high modulus polyethylene Alcohol fiber (Anhui Wanwei Group) 1.2%, the balance is porcelain slag powder.

[0039] Its preparation method of above-mentioned blast furnace slag composite powder comprises the following steps:

[0040] 1) Add 10% water of the total weight of raw materials to the acrylic polymer emulsion, stir evenly to obtain a polymer suspension;

[0041] 2) Crush the porcelain slag powder and mix it with the remaining raw materials, then add it to the polymer suspension, stir it into a uniform paste, let it stand for 2 hours, and dehydrate it to a water content of 7% to obtain a blast furnace slag composite powder.

[0042] The above-mentioned dry powder is pressed into a plate by an 8,000-ton pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com