Method for extracting soy protein, oligosaccharide and isoflavone from soybean wastewater by one-step process

A technology of soybean product wastewater and soybean isoflavones, applied in the field of extracting nutrients, can solve the problems of product decolorization, complex operation and comprehensive utilization treatment, large amount of organic solvent, etc., and achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

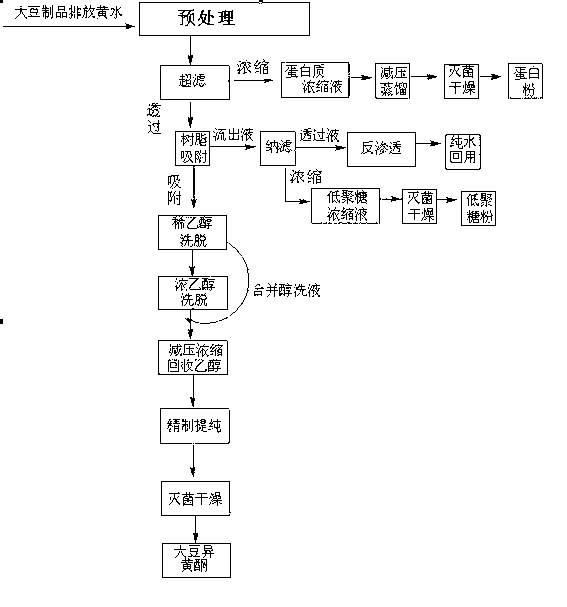

[0035] Embodiment 1: as figure 1 Shown:

[0036] Add 101 metal remover to the yellow water discharged from soybean products, send it into a bag filter and filter it through a microfilter to obtain clarified yellow water discharged.

[0037] Under the conditions of temperature 10-45°C and pressure 0.5-6 Pa, the clarified and discharged yellow water is sent to the ultrafiltration membrane, and the ultrafiltration membrane cuts off between 6000Da and 10000Da, so the soybean protein liquid and permeate are separated and concentrated.

[0038] The concentrated soybean protein liquid is spray-dried to obtain white soybean protein powder.

[0039] Ultrafiltration membrane permeate (containing soy isoflavones and oligosaccharides) absorbs soy isoflavones through weakly polar macroporous resin at a flow rate of 2-4BV / h. Use 20-30% ethanol and 70-80% ethanol to elute the soybean isoflavones adsorbed by the resin respectively, combine the lotions, concentrate under reduced pressure and...

Embodiment 2

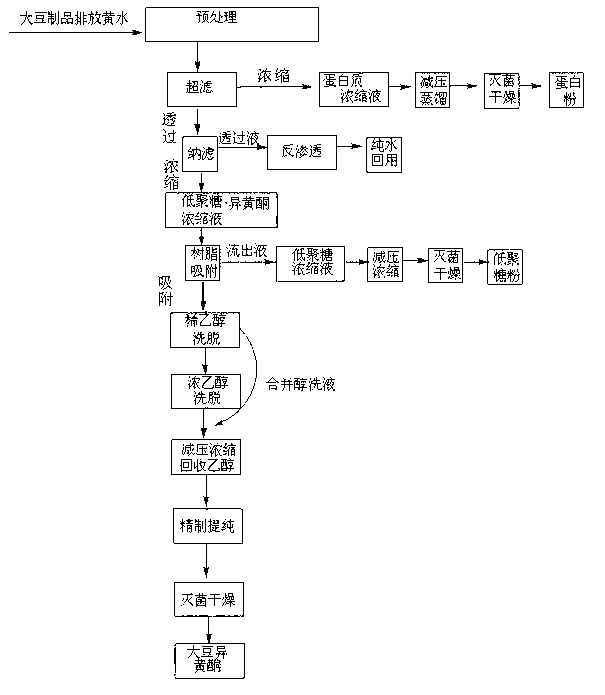

[0043] Embodiment 2: as figure 2 Shown:

[0044] Add 101 metal remover to the yellow water discharged from soybean products, send it into a bag filter and filter it through a microfilter to obtain clarified yellow water discharged.

[0045] Under the conditions of temperature 10-45°C and pressure 0.5-6 Pa, the clarified and discharged yellow water is sent to the ultrafiltration membrane, and the ultrafiltration membrane cuts off between 6000Da and 10000Da, so that soybean protein liquid and permeate are separated.

[0046] The concentrated soybean protein liquid is spray-dried to obtain white soybean protein powder.

[0047] The ultrafiltration membrane permeate (containing soybean isoflavones and oligosaccharides) is sent to the nanofiltration membrane at a temperature of 25-45°C and a pressure of 1.5-6 Pa. The nanofiltration membrane cuts off between 66Da-300Da, so it is separated and concentrated to obtain Soybean oligosaccharide concentrate, soy isoflavone concentrate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com