Preparation method and use of paper surface sizing agent

A technology of surface sizing agent and sizing agent, which is applied in the direction of water-repellent addition, etc., can solve the problems of large molecular weight that cannot be filled, small grooves on the paper surface and poor strength, and achieve the effect of abundant raw materials, easy operation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

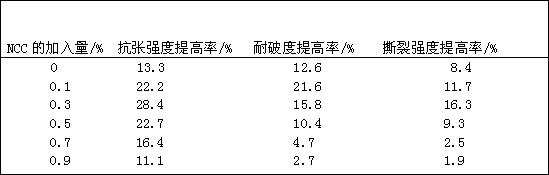

Embodiment 1

[0012] (1) Preparation of nanocrystalline cellulose colloid: using microcrystalline cellulose powder as raw material, under stirring at a stirring speed of 300r / min, slowly add microcrystalline cellulose powder according to the solid-to-liquid ratio of 1:10 In a sulfuric acid solution with a concentration of 64%, the reaction temperature is a water bath at 50°C. After reacting for 90 minutes, add water to terminate the reaction; centrifuge the obtained mixed solution in a centrifuge with a speed of 11000r / min for 5 to 6 times, and centrifuge each time 10 minutes; then put the collected nano-microcrystalline cellulose colloid in a dialysis bag with a specification of 8000-14000 until the pH of the colloid is 6-7. (2) Preparation of surface sizing agent: first, put the gelatinized cationic starch latex in a beaker and stir it on a magnetic stirrer with a rotation speed of 400r / min for 15 min, then mix the nano-microcrystalline cellulose colloid according to Add 0.1% to the catio...

Embodiment 2

[0014] (1) Preparation of nano-microcrystalline cellulose colloid: using microcrystalline cellulose powder as raw material, under stirring at a stirring speed of 300r / min, slowly add microcrystalline cellulose powder according to the solid-to-liquid ratio of 1:8 into a sulfuric acid solution with a concentration of 65%, and the reaction temperature is a water bath at 50°C. After reacting for 120 minutes, add water to terminate the reaction; centrifuge the obtained mixed solution in a centrifuge with a speed of 11000r / min for 5 to 6 times, and centrifuge each time 10 minutes; then put the collected nano-microcrystalline cellulose colloid in a dialysis bag with a specification of 8000-14000 until the pH of the colloid is 6-7. (2) Preparation of surface sizing agent: First, put the gelatinized cationic starch latex in a beaker and stir it on a magnetic stirrer with a rotation speed of 400r / min for 15 minutes, and mix the nanocrystalline cellulose colloid at 0.3 % ratio was added ...

Embodiment 3

[0016] (1) Preparation of nanocrystalline cellulose colloid: using microcrystalline cellulose powder as raw material, under stirring at a stirring speed of 290r / min, slowly add microcrystalline cellulose powder according to the solid-to-liquid ratio of 1:9 into a sulfuric acid solution with a concentration of 65%, and the reaction temperature is a water bath at 50°C. After reacting for 100 minutes, add water to terminate the reaction; centrifuge the obtained mixed solution in a centrifuge with a rotating speed of 11000r / min for 5 to 6 times, and centrifuge each time 10 minutes; then put the collected nano-microcrystalline cellulose colloid in a dialysis bag with a specification of 8000-14000 until the pH of the colloid is 6-7. (2) Preparation of surface sizing agent: First, put the gelatinized cationic starch latex in a beaker and stir it on a magnetic stirrer with a rotation speed of 300r / min for 15 min, then mix the nano-microcrystalline cellulose colloid according to Add 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com