Compound microbial active filling material for removing sulphur-containing repugnant substances, as well as preparation and application thereof

A technology of composite microorganisms and composite microorganisms, applied in the field of environmental governance, can solve problems such as small specific surface area, large pressure loss, and large filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0063] Example 1: A microbial active filler for removing sulfur-containing malodorous substances and its preparation method.

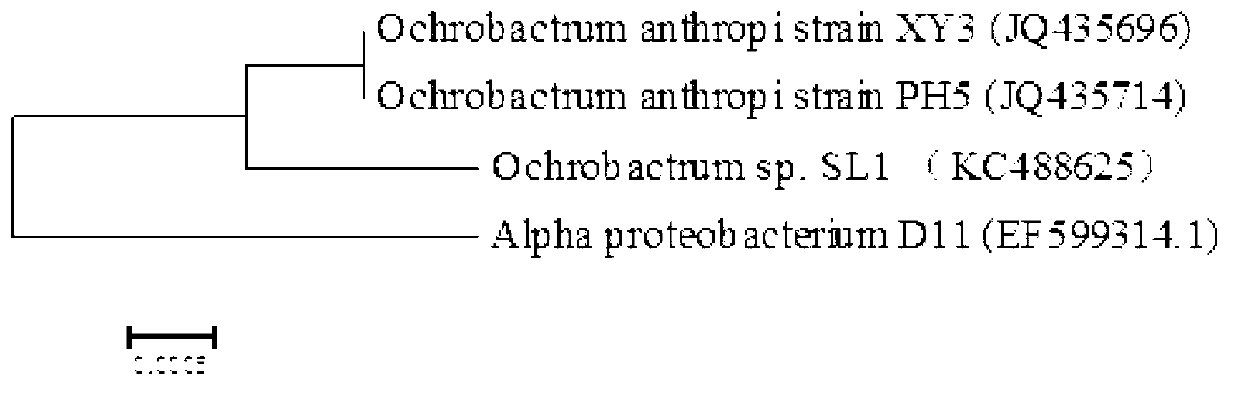

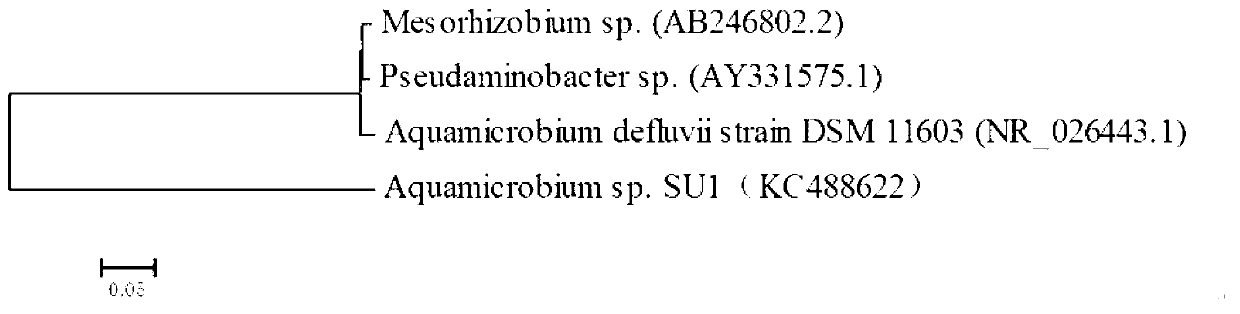

[0064] A composite microbial active filler for removing sulfur-containing malodorous substances, the filler is loaded with Ochrobactrum anthropi SL1 and Aquamicrobium defluvii SU1; the preservation number of Ochrobactrum anthropi SL1 is CGMCC No.7400, the preservation number of Aquamicrobium defluvii SU1 is CGMCC No.7399;

[0065] The filler is a polyurethane foam block;

[0066] The packing density is 0.8kg / m 3 , the porosity is 86%, the particle size is 30mm;

[0067] The composite microorganism is attached to the filler in the form of bacterial suspension;

[0068] The mass ratio of the composite microbial suspension to the polyurethane foam block is 100:10;

[0069] The concentration of Pallidus human SL1 cells in the composite microbial active filler is greater than 10 6 CFU / g, the bacterial concentration of water bacteria SU1 is greater than...

example 2

[0085] Example 2: A microbial active filler degrades H 2S gas application.

[0086] Another object of the present invention is to utilize composite microorganism active filler to carry out odorous gas treatment, especially in degrading H 2 For the application of S gas, the specific steps are as follows:

[0087] (1) Place the composite microbial active filler containing human Pallidinus SL1 and water microbacteria SU1 in a container, and pass H 2 S gas to H 2 S gas is the sulfur source to activate the composite microbial active filler; the activation time is 7 days;

[0088] The H 2 The concentration of S is 100ppm;

[0089] (2) The activated composite microbial active filler is placed in a bioreactor, and the gas containing sulfur-containing odorous substances is introduced, and the sulfur-containing odorous substances in the exhaust gas are purified with Pallidinus anthropus SL1 and water microbacteria SU1, and the volume of the composite microbial active filler 100m ...

example 3

[0091] Example 3: Use effect experiment (the filler prepared in Example 1 was subjected to the following three experiments respectively).

[0092] (1) Treat the sulfur-containing malodorous gas escaped from the sludge sedimentation tank of the sewage plant, and the gas flow rate is 35m 3 / h, the residence time is 1-3mins, and it operates at room temperature. The intake concentration of hydrogen sulfide is: 14.86mg / m 3 , the output gas concentration is 0.03mg / m 3 , which is lower than the emission standard of odorous pollutants formulated by the state, and the removal rate reaches 99%.

[0093] (2) Used to treat sulfur-containing malodorous gases produced by sludge composting, the concentrations of hydrogen sulfide and ethanethiol are 18mg / m3 3 and 2.53mg / m 3 , the gas flow rate is 70m 3 / h, the residence time is 1-3mins, operating at room temperature, the removal rates of hydrogen sulfide and ethanethiol are both greater than 90%.

[0094] (3) Landfill, disposal contains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com