Preparation method for fluid of increasing viscoelasticity of anionic/cationic surfactant through polymer

A technology of surfactant and viscoelasticity, which is applied in the field of preparation of polymer-enhanced surfactant viscoelastic fluid, can solve the problem of small threshold resistance to external force, achieve good stability, enhance viscoelasticity, and enhance resistance to shear dilution effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Use Br with a concentration of 0.1 mol / L - The quaternary ammonium salt cationic surfactant-tetradecyltrimethylammonium hydroxide aqueous solution, which is the counter ion, passes through the exchange column equipped with anion exchanger, and is exchanged into OH by anion exchange method. - It is the aqueous solution of quaternary ammonium base type cationic surfactant of counter ion;

[0039] (2) Use the prepared standard solution of potassium hydrogen phthalate, use phenolphthalein as indicator, and take some of the obtained in step (1) as OH - Calibrate the aqueous solution of quaternary ammonium base type cationic surfactant as the counter ion to obtain its accurate concentration;

[0040] (3) Take the OH obtained in step (1) - The quaternary ammonium base cationic surfactant aqueous solution that is the counter ion is added fatty acid-lauric acid in an equimolar amount to the surfactant according to the measured concentration, and after heating and shaking t...

Embodiment 2

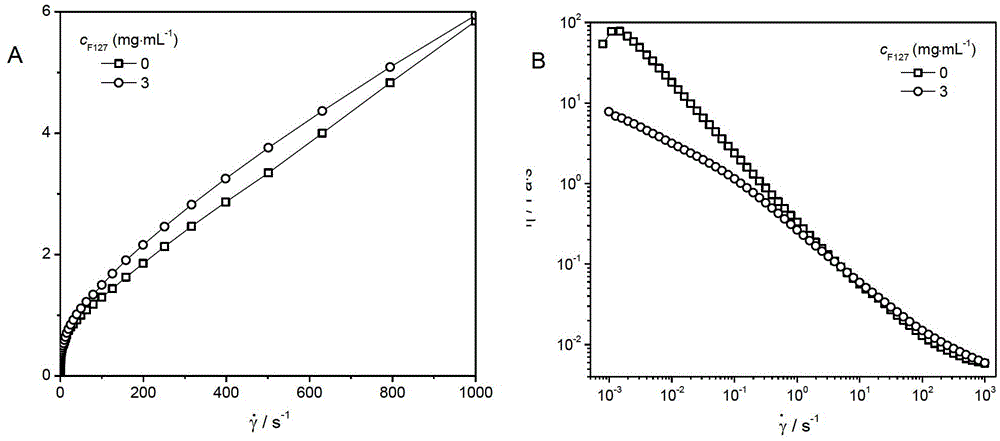

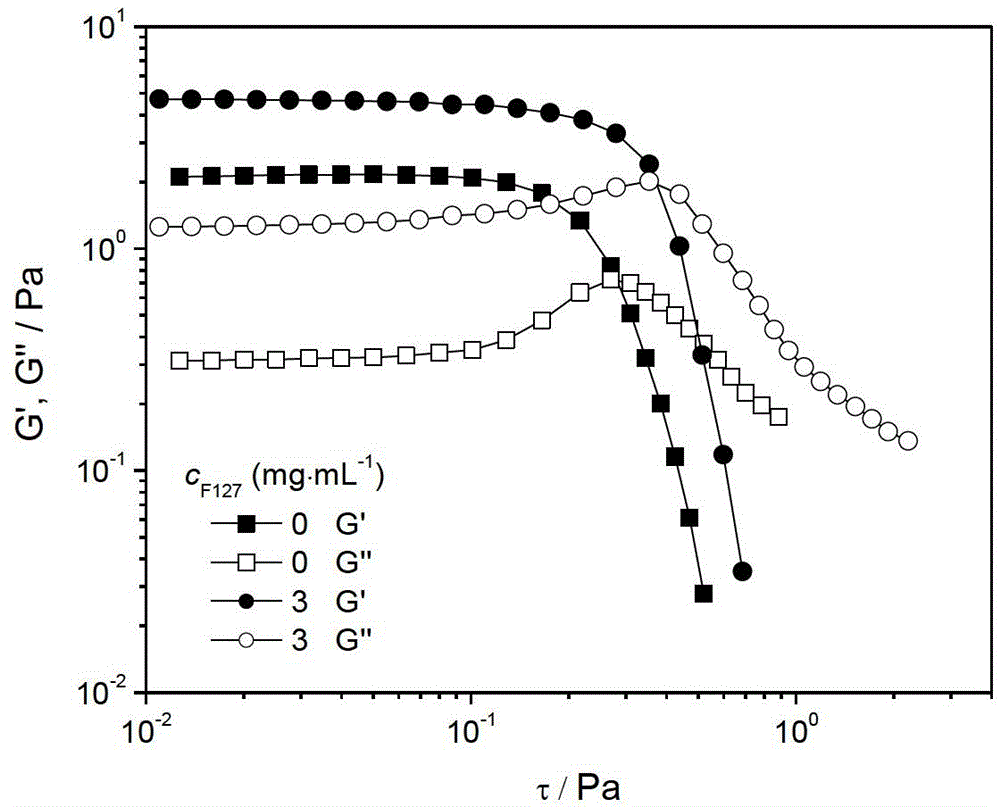

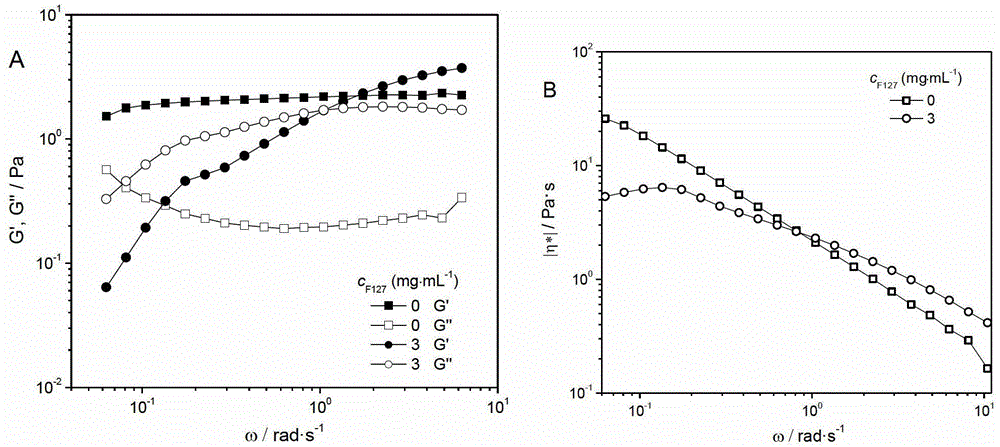

[0045] The steps are the same as in Example 1, except that the added polymer is replaced by Pluronic F68, and the added amount is 1.0 mg / mL. The results of steady shear and oscillatory shear of the product are shown in Figure 4 , Figure 5 with Image 6 middle.

Embodiment 3

[0047] The steps are the same as in Example 2, except that the amount of polymer Pluronic F68 in the target sample is increased to 3.0 mg / mL. The results of its product oscillatory shear are shown in Figure 7 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com