Device and method for treating electrophoretic coating waste water

An electrophoretic coating and treatment device technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high settling requirements, large labor, and difficult to achieve total nickel discharge Standards and other issues to ensure stable operation and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in combination with specific embodiments.

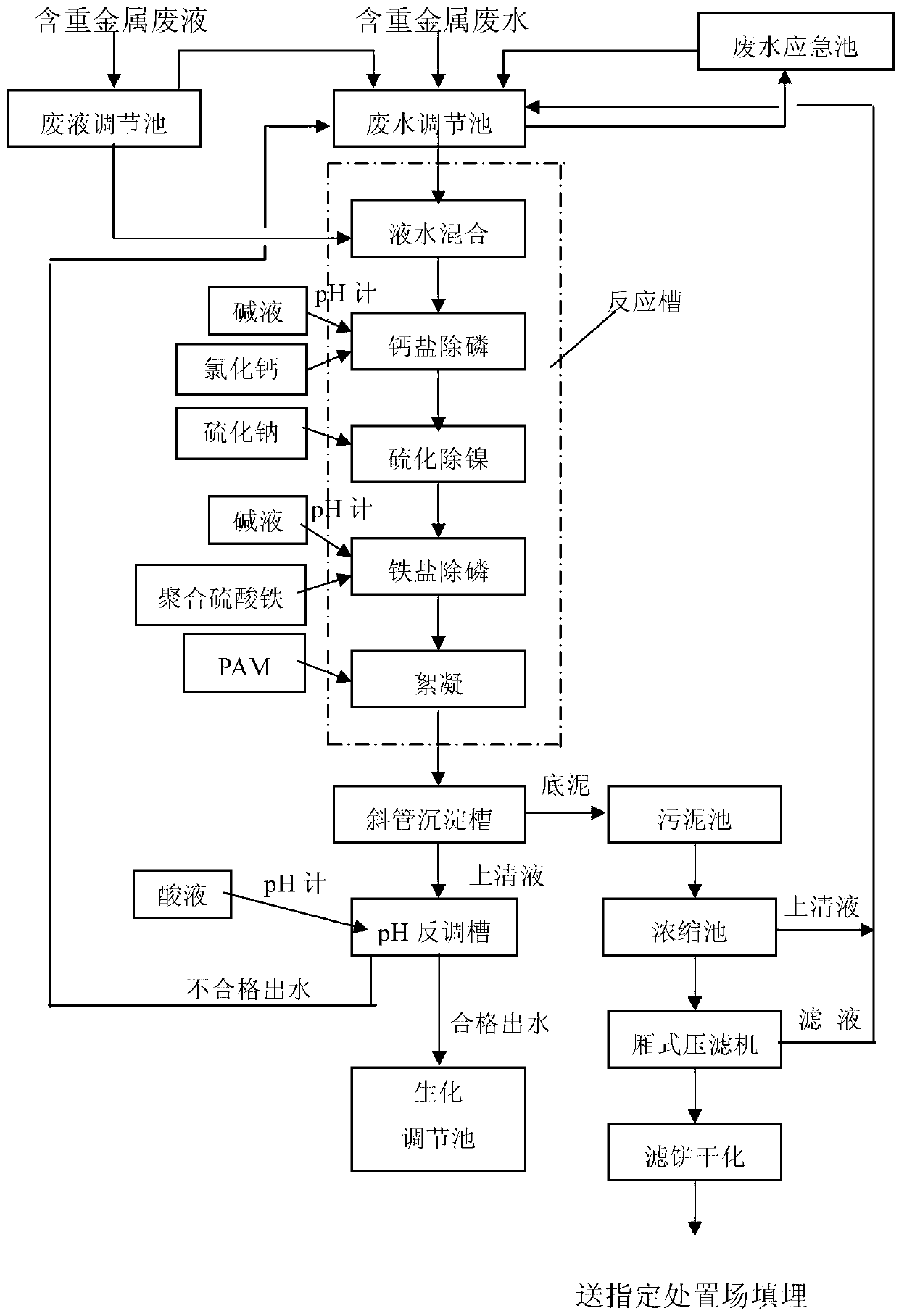

[0016] As shown in the accompanying drawings, the present invention is a treatment device for electrophoretic coating wastewater, including a waste liquid regulating pool and a waste water regulating pool, each of the waste liquid regulating pool and the waste water regulating pool is provided with a perforated pipe respectively, and the waste liquid Both the liquid adjustment pool and the waste water adjustment pool are respectively connected to a reaction tank through a lift pump. The reaction tank is provided with a pH probe, and the reaction tank is also connected with an alkali addition pipeline. The alkali addition pipeline is equipped with a The electromagnetic valve controlled by the device; the reaction tank is divided into four reaction chambers along the reaction route, including the first reaction chamber, the second reaction chamber, the third reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com