Nepheline syenite powder and production method thereof

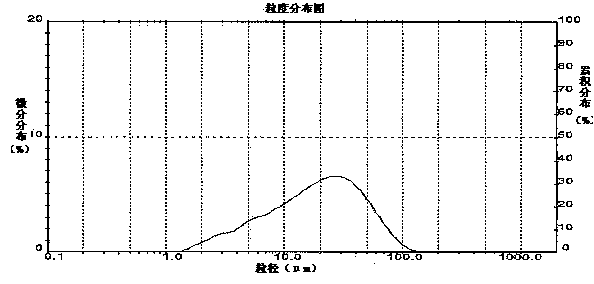

A technology of nepheline syenite and production method, which is applied in the field of mineral powder, can solve the problems of unconcentrated particle size distribution, low purity and high iron content of powder, and achieve the effects of concentrated particle size distribution, excellent performance and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The raw materials of this example are relatively stable domestic raw materials, Sichuan Nanjiang nepheline stone and Guangdong Fogang nepheline stone for formula optimization.

[0029] Raw material 1 is the original ore of Xiashi in Nanjiang, Sichuan, and its chemical composition is silicon dioxide SiO in parts by weight. 2 41.4 parts, aluminum oxide Al 2 o 3 28.1 parts, potassium oxide K 2 O 4.3 parts, sodium oxide Na 2 O 10.9 parts, ferric oxide Fe 2 O 1.7 parts, loss on ignition 5.8 parts.

[0030] The second raw material is nepheline ore from Fogang, Guangdong, and its chemical composition is silicon dioxide SiO in parts by weight. 2 61.1 parts, aluminum oxide Al 2 o 3 18.1 parts, potassium oxide K 2 O 6.0 parts, sodium oxide Na 2 O 6.7 parts, ferric oxide Fe 2 o 3 5.1 parts, loss on ignition 1.0 parts. Wherein, the loss on ignition is the weight percentage lost after burning the raw material dried at 105-110°C at 1000-1100°C.

[0031] The specific...

Embodiment 2

[0038] On the basis of Example 1, the moisture content of the semi-finished product obtained in step (2) in this embodiment is 22%, the semi-finished product in step (3), raw material 1 and water after step (1) by weight ratio 5: The ratio of 3:2 is added to the ball mill for grinding at the same time, and when the moisture content of the material in step (4) is 22%, it enters the dryer for drying process.

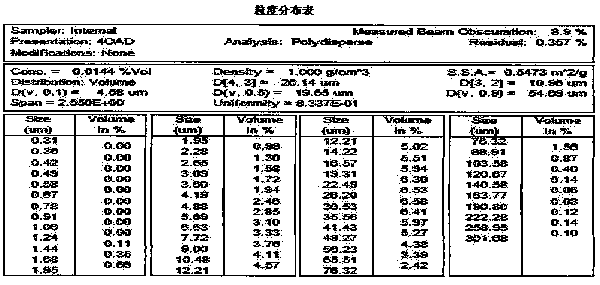

[0039] The technical indicators of the product in this example were tested, and the nepheline syenite powder had a magnetic substance weight content of 0.016%, a water weight content of 0.3%, a product particle size of +45 μm less than 8%, and a particle size of -5 μm less than 20%. , the internal exposure index I of the radionuclide limit of the product Ra ≤0.1, external exposure index I γ ≤0.4, the linear thermal expansion coefficient of the product is 9.6×10 -6 / °C, the pH value of the product is 10.5.

Embodiment 3

[0041] On the basis of Example 1, the moisture content of the semi-finished product obtained in step (2) in this embodiment is 24%, the semi-finished product in step (3), raw material 1 and water after step (1) are by weight 4: The ratio of 2:1 is added to the ball mill at the same time for grinding. In step (4), when the moisture content of the material is 24%, it enters the dryer for drying process.

[0042] The technical indicators of the product in this embodiment were tested, and the magnetic substance weight content in the nepheline syenite powder was 0.02%, the water weight content was 0.3%, the product particle size was +45 μm less than 8%, and the particle size was -5 μm less than 20%. , the internal exposure index I of the radionuclide limit of the product Ra ≤0.4, external exposure index I γ ≤0.7, the linear thermal expansion coefficient of the product is 10.1×10 -6 / °C, the pH value of the product is 10.3.

[0043] The chemical composition of the product in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com