Method for preparing high-purity 1-deoxynojirimycin with combined membrane separation and column chromatography technology

A technology of deoxynojirimycin and column chromatography, which is applied in the field of enrichment of 1-deoxynojirimycin by combined membrane separation and column chromatography technology, can solve the problems of complicated treatment process, mixed with organic solvents, long elution time, etc. , to achieve good separation selectivity, high efficiency, and increase the effect of sample loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

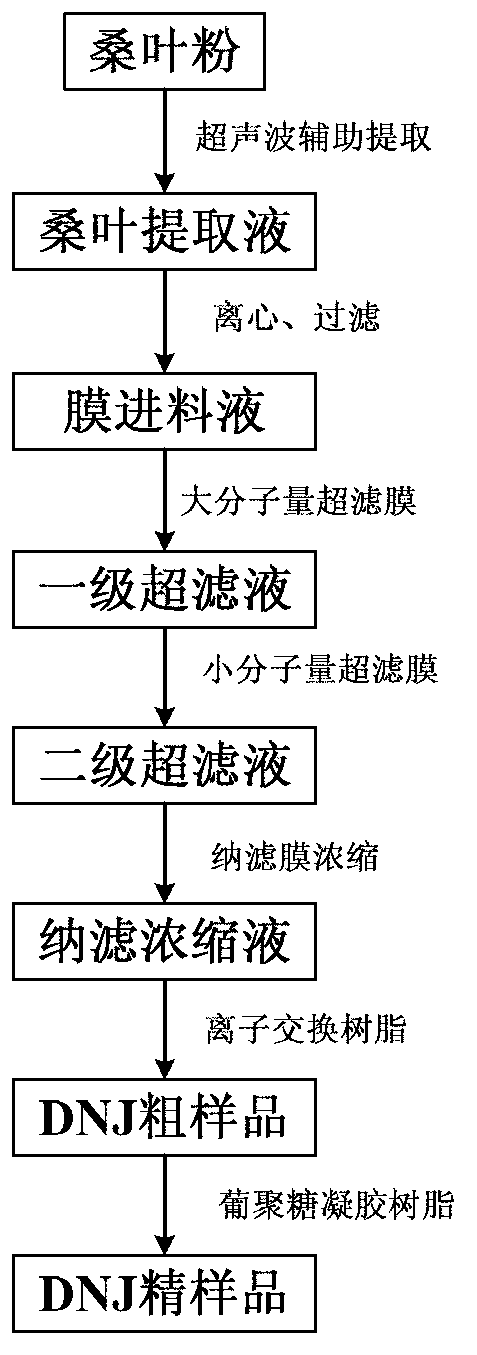

[0031] process such as figure 1 ,Specific steps are as follows:

[0032] (1) Ultrasonic water extraction: crush and sieve the dry raw materials to obtain coarse powder. Weigh an appropriate amount of coarse powder, add distilled water at a liquid-to-solid ratio (mL / g) of 40:1, heat in a water bath at 70°C for 30 minutes with ultrasonic treatment, centrifuge and filter, collect the supernatant, repeat the extraction of the precipitate once according to the above steps, and combine twice The supernatant is the extract.

[0033] (2) Pretreatment: centrifuge the extract obtained in step (1), and then pass it through a 2.0 μm microporous membrane to obtain an ultrafiltration feed solution.

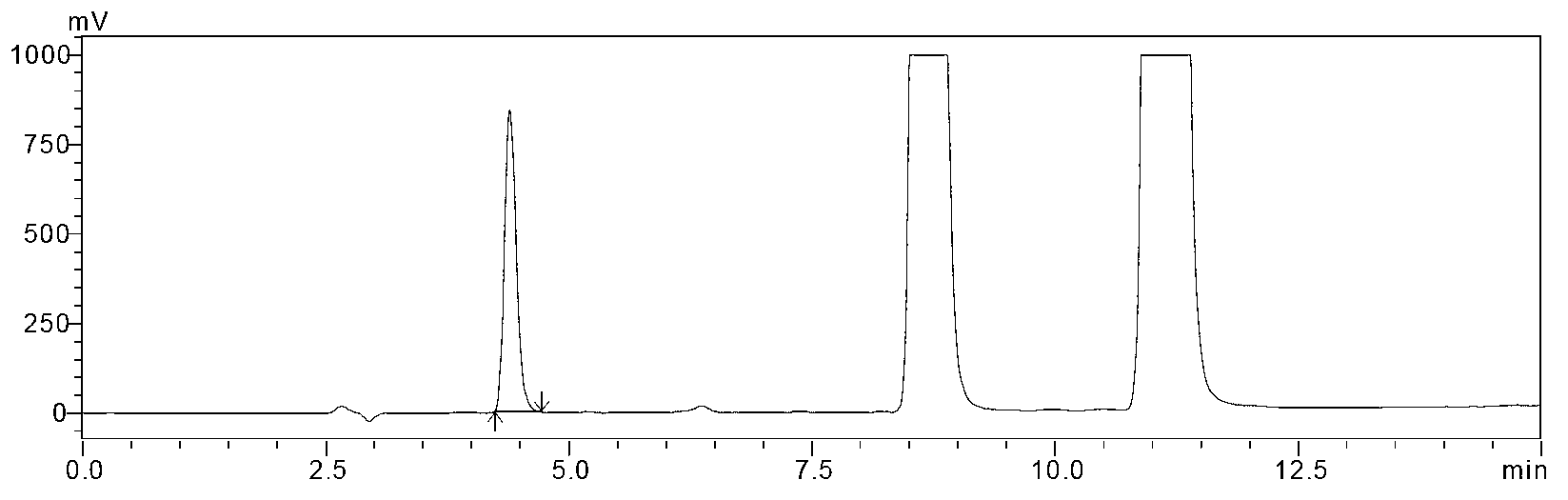

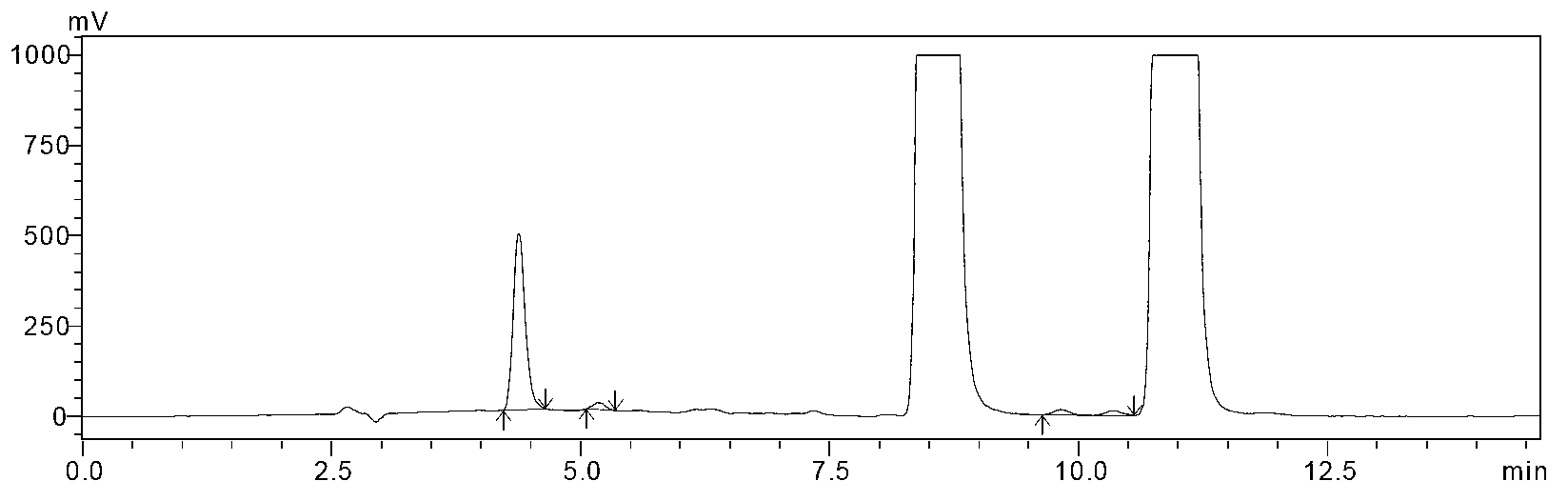

[0034] (3) Secondary ultrafiltration: the first ultrafiltration membrane of the ultrafiltration feed liquid obtained in step (2), during the ultrafiltration process, add deionized water to the feed liquid tank, and collect the first ultrafiltration permeate ; Then the permeate is treated wit...

Embodiment 2

[0039] In step (1) ultrasonic water extraction, use a liquid-to-material ratio of 10:1 (mL / g), and then use an ultrafiltration membrane with a molecular weight cut-off of 20kDa for the first ultrafiltration in step (3), The operating pressure is 0.8MPa, and the feed liquid temperature is 30°C; during the second ultrafiltration, an ultrafiltration membrane with a molecular weight cut-off of 1.0kDa is preferred, preferably 1.2MPa. Other operations are the same as in Example 1. The purity of the final DNJ refined sample was 83.56%.

Embodiment 3

[0041]In step (1) ultrasonic water extraction, use a liquid-to-material ratio of 20:1 (mL / g), and then use an ultrafiltration membrane with a molecular weight cut-off of 8kDa for the first ultrafiltration in step (3), The operating pressure is 0.8MPa, and the feed liquid temperature is 30°C; during the second ultrafiltration, the ultrafiltration membrane with a molecular weight cut-off of 1.0kDa is preferred, preferably 1.2MPa; Filtrate permeate for treatment, the preferred operating pressure is 1.2MPa. Other operations are the same as in Example 1. The purity of the final DNJ refined sample is 85.24%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com