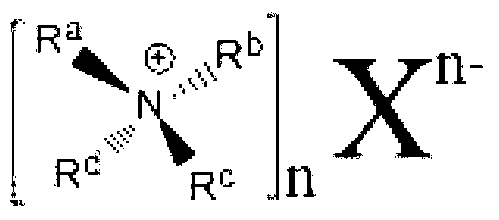

Method for synthetizing hydrogenated bisphenol A epoxy resin under catalysis of ammonium salt

A technology for hydrogenating bisphenol and epoxy resin, applied in the field of epoxy resin preparation, can solve problems such as inability to control product color well, and achieve the effects of easy industrial production and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In a 1000ml four-neck flask equipped with an electric heating pack heating device, a stirrer, a condenser, a thermometer, and a dropping funnel, use dry air to purge the entire system, add 100g of hydrogenated bisphenol A and 50g of solvent toluene, and start stirring , heated to 30°C with an electric heating pack, and added 0.32g of ammonium acetate and 16.7g of sodium hydroxide. Add 115g of epichlorohydrin dropwise through the dropping funnel to carry out etherification reaction, fully react for 15 hours, and the reaction temperature is 30°C. During the dropping process, observe the temperature and color changes of the system, adjust the dropping speed, and control the dropping time to 2-5 hours. Then 11.2 g of 30% sodium hydroxide aqueous solution was added dropwise through the dropping funnel, the reaction time was 2 h, and the reaction temperature was 100°C. In order to reduce the viscosity of the system, add 200g of toluene after the reaction reaches the process ...

Embodiment 2

[0049] In a 1000ml four-necked flask equipped with an electric heating pack heating device, a stirrer, a condenser, a thermometer, and a dropping funnel, use dry air to purge the entire system, add 100g of hydrogenated bisphenol A and 80g of solvent xylene, and start Stir, heat the electric heating pack to 100°C, add 2.3g of phenyltrimethylammonium formate, and 30g of sodium ethoxide. Add 150 g of methyl epichlorohydrin dropwise through the dropping funnel to carry out etherification reaction, fully react for 2 hours, and the reaction temperature is 100°C. During the dropping process, observe the temperature and color changes of the system, adjust the dropping speed, and control the dropping time to 2-5 hours. Then, 140 g of calcium hydroxide aqueous solution with a mass fraction of 11% was added dropwise through the dropping funnel, the reaction time was 8 hours, and the reaction temperature was 100°C. In order to reduce the viscosity of the system, add 400g of xylene after ...

Embodiment 3

[0057] In a 1000ml four-neck flask equipped with an electric heating pack heating device, a stirrer, a condenser tube, a thermometer, and a dropping funnel, use dry air to purge the entire system, add 100g of hydrogenated bisphenol A and 60g of solvent methyl isobutyl Base ketone, start stirring, heat the electric heating pack to 70°C, add 2.5g octadecyltrimethylammonium bromide, and 25g sodium methoxide. Add 120 g of epibromohydrin dropwise through the dropping funnel to carry out etherification reaction, fully react for 8 hours, and the reaction temperature is 60°C. During the dropping process, observe the temperature and color changes of the system, adjust the dropping speed, and control the dropping time to 2-5 hours. Then 20 g of 15% sodium ethoxide ethanol solution was added dropwise through the dropping funnel, the reaction time was 4 hours, and the reaction temperature was 70°C. In order to reduce the viscosity of the system, add 208g of methyl isobutyl ketone after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com