Seawater base fracturing fluid

A technology of seawater and base fluid, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of reducing swelling performance, reducing hydrodynamic volume, hindering water molecules from penetrating into the polymer, and avoiding the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

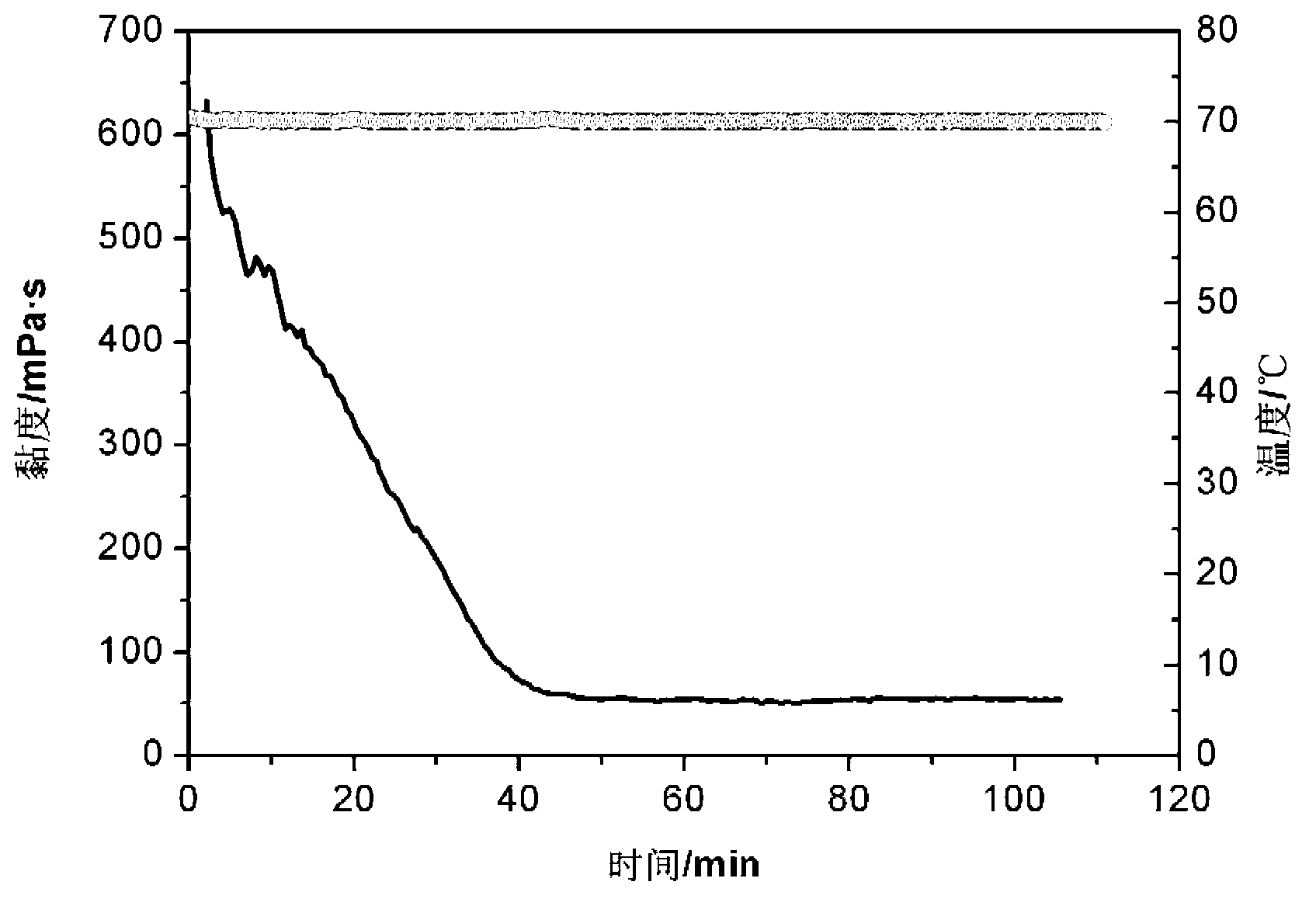

[0029] Add 990.9ml of seawater into a mixer with a capacity of 2000ml, add 5g of KCl and 0.1g of formaldehyde under stirring, then weigh 3g of betaine-type amphoteric guar gum, slowly add it into seawater under stirring, and stir at high speed for 5 minutes; Then add 1g of cetyltrimethylammonium bromide; stir in a mixer for 5 minutes to obtain a uniform transparent seawater base liquid; take 100ml of the seawater base liquid prepared above, add 0.2g of zirconium acetate under stirring, and continue stirring for 2min Finally, the seawater base liquid reacts completely with the cross-linking agent to form jelly, and the preparation of the jelly solution is completed; add 0.1 g of sodium persulfate to the jelly formed by cross-linking under stirring, and keep the constant temperature in a water bath at 50°C. After 3 hours, The jelly is completely broken and hydrated. The apparent viscosity of the base liquid measured with a FANN-35 viscometer is 36mPa s; the rheological propertie...

Embodiment 2

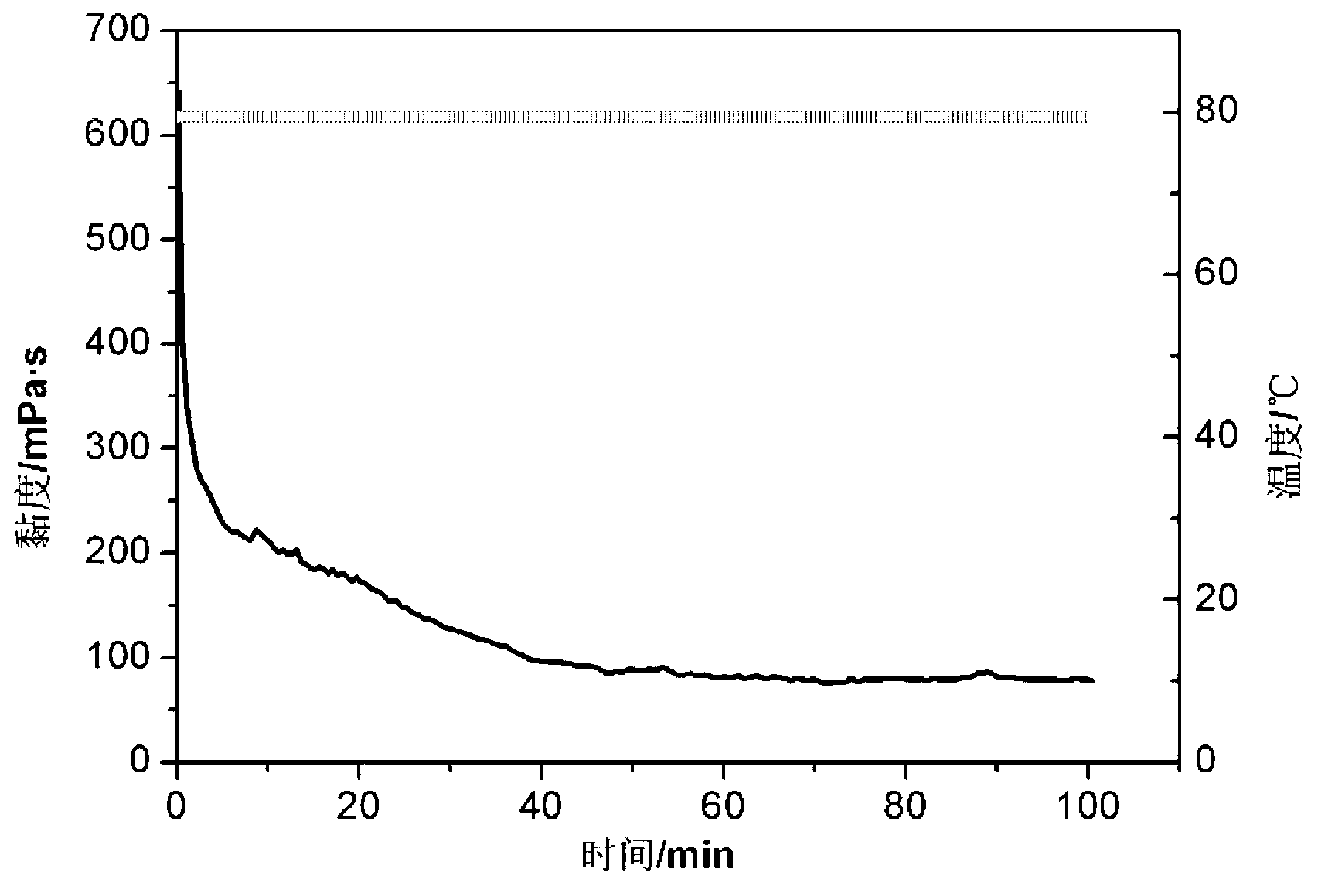

[0031] Add 981.5ml of seawater into a mixer with a capacity of 2000ml, and add 10g of NH under stirring 4 Cl and 0.5g formaldehyde, then take by weighing 4g phosphate-type amphoteric guar gum, slowly add it in seawater under stirring state, high-speed stirring 5min; Then add 4g hexadecyltrimethylammonium bromide; Stir for 5 minutes to obtain a uniform transparent seawater base solution; take 100ml of the above prepared seawater base solution, add 0.4g of aluminum chloride under stirring, continue stirring for 2 minutes, the seawater base solution and the cross-linking agent completely react to form a jelly, and complete Preparation of jelly solution; add 0.3 g of ammonium persulfate to the jelly formed by cross-linking under stirring, keep constant temperature in a water bath at 50°C, and after 2 hours, the jelly is completely broken and hydrated. The apparent viscosity of the base liquid measured with a FANN-35 viscometer is 42mPa s; the rheological properties of the jelly ar...

Embodiment 3

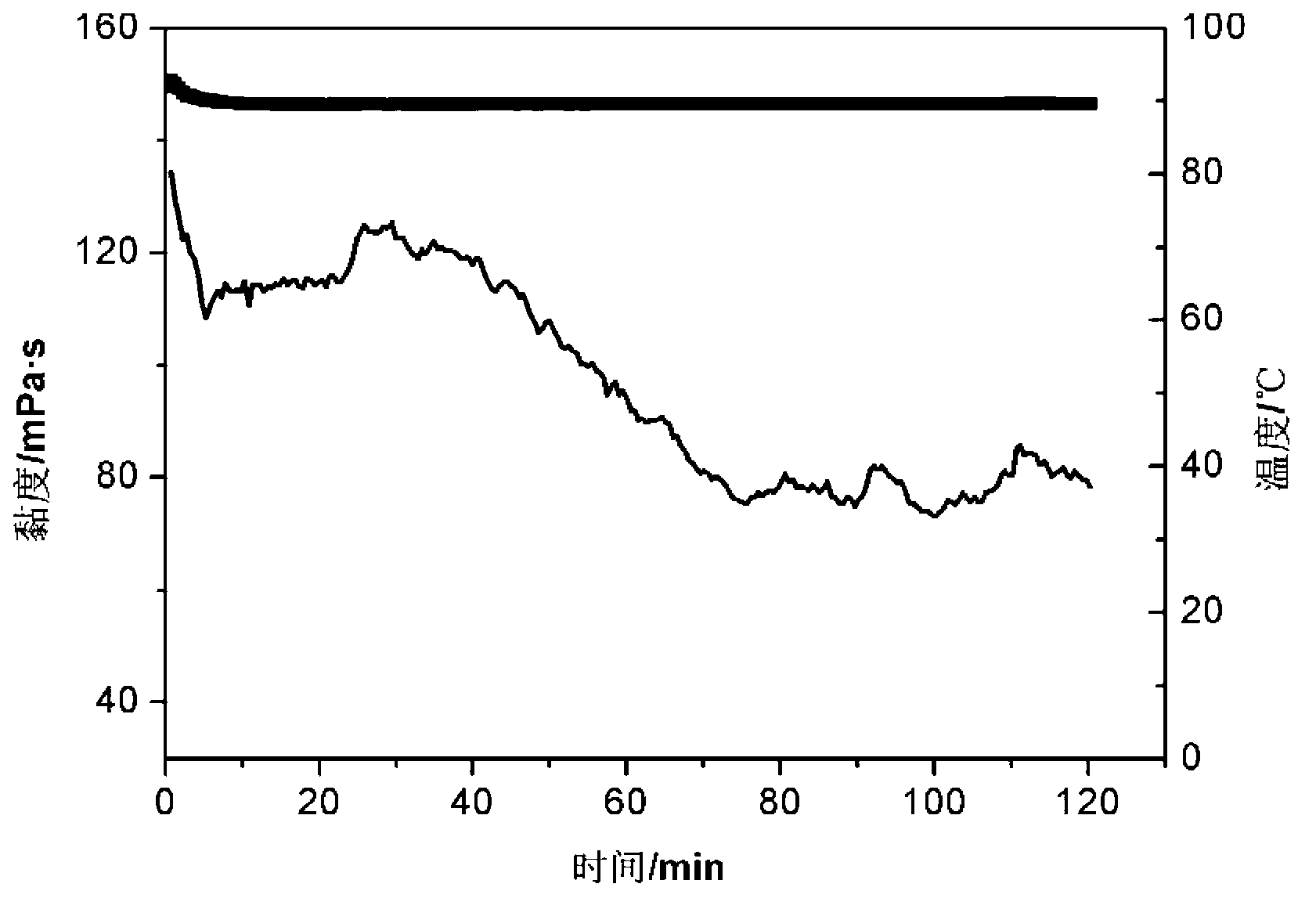

[0033] Add 972.2ml of seawater into a mixer with a capacity of 2000ml, and add 15g of NH under stirring 4 Cl and 0.8g formaldehyde, then take by weighing 5g phosphate-type amphoteric guar gum, slowly add it in the seawater under stirring state, high-speed stirring 5min; Then add 7g dodecyltrimethylammonium bromide; Stir in the medium for 5 minutes to obtain a uniform transparent seawater base liquid; take 100ml of the seawater base liquid prepared above, add 0.7g of zirconium acetate under stirring, continue stirring for 2 minutes, the base liquid and the cross-linking agent completely react to form a jelly, and the jelly is completed Solution preparation; add 0.6 g of sodium persulfate to the gel formed by cross-linking under stirring, keep constant temperature in a water bath at 50°C, and after 2 hours, the gel is completely broken and hydrated. The apparent viscosity of the base liquid measured with a FANN-35 viscometer is 72mPa·s; the rheological properties of the jelly ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com