Silicon single crystal manufacturing method, silicon single crystal and wafer

A silicon single crystal and wafer technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of inability to achieve radial uniformity of resistivity and change of wafer resistivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Examples and comparative examples of the silicon single crystal production method according to this embodiment of the present invention are described below.

[0082] Manufacture of silicon single crystal

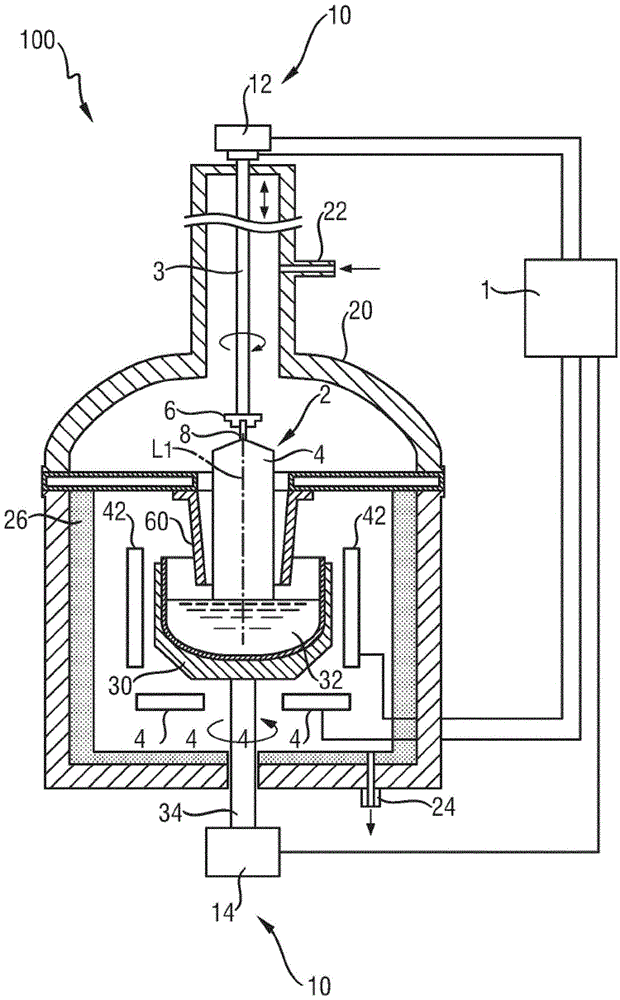

[0083] An apparatus for producing a silicon single crystal by the CZ method was used to grow a silicon single crystal (ingot) with a diameter of 200 mm.

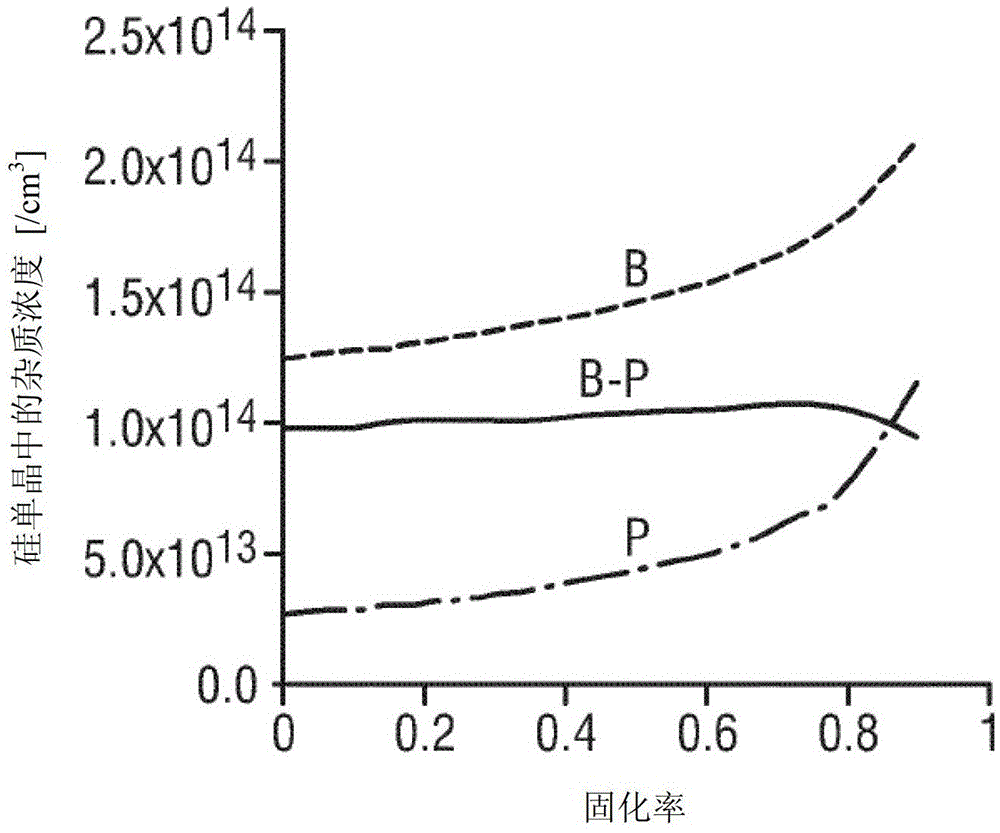

[0084] Here, an initial silicon melt has a boron concentration and a phosphorus concentration as shown below, and a seed crystal is immersed in the initial silicon melt to grow a silicon single crystal. The crystal growth rate was set at 0.9 mm / min, and the cooling rate at the edge portion of the crystal was set at 1.9 times the cooling rate at the central portion of the crystal.

[0085] (1) Embodiment 1

[0086] Addition of boron and phosphorus to the nascent silicon melt, resulting in a boron concentration of 1.6E14 atoms / cm 3 , the phosphorus concentration reaches 7.2E13 atoms / cm 3 (The ratio of phosphorus c...

Embodiment 2

[0088] Boron and phosphorous are added to the nascent silicon melt, resulting in a boron concentration of 4.0E14 atoms / cm 3 , the phosphorus concentration reaches 1.8E14 atoms / cm 3 (The ratio of phosphorus concentration to boron concentration is 0.45).

Embodiment 3

[0090] Boron and phosphorus are added to the nascent silicon melt to bring the boron concentration to 1.1E14 atoms / cm 3 , the phosphorus concentration reaches 4.6E13 atoms / cm 3 (The ratio of phosphorus concentration to boron concentration is 0.42).

[0091] (4) Embodiment 4

[0092] Addition of boron and phosphorus to the nascent silicon melt, resulting in a boron concentration of 1.6E14 atoms / cm 3 , the phosphorus concentration reaches 7.5E13 atoms / cm 3 (The ratio of phosphorus concentration to boron concentration is 0.47).

[0093] (5) Example 5

[0094] Addition of boron and phosphorus to the nascent silicon melt, resulting in a boron concentration of 1.6E14 atoms / cm 3 , the phosphorus concentration reaches 8.0E13 atoms / cm 3 (The ratio of phosphorus concentration to boron concentration is 0.50).

[0095] (6) Comparative Example 1

[0096] Boron is added to the nascent silicon melt to achieve a boron concentration of 1.0E14 atoms / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com