Method and device for removing mercury in flue gas by utilizing organic wastes

A technology for organic waste and flue gas, applied in the field of environmental pollution control, can solve the problems of high operating cost, high investment and operating cost, increased carbon content, etc., and achieves the effects of improving the atmospheric environment, increasing the enthusiasm for operation, and solving treatment problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

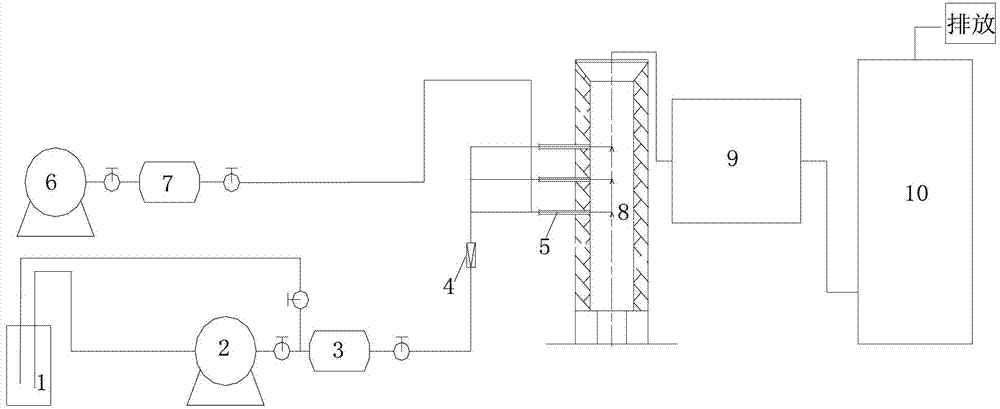

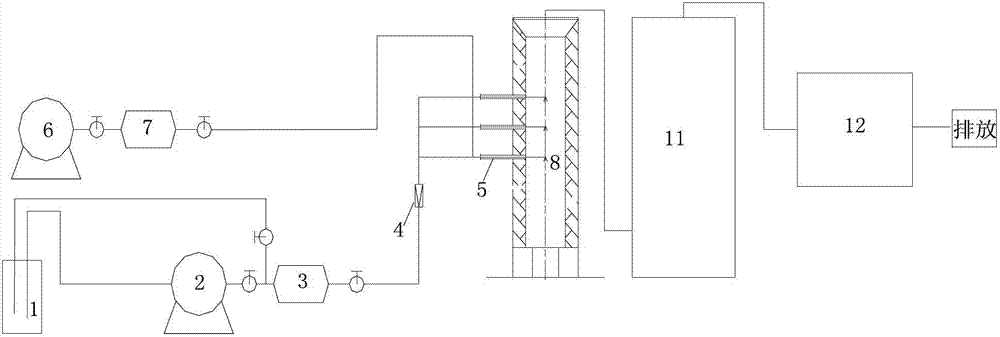

Image

Examples

Embodiment 1

[0031]Taking the coal chemical industry organic wastewater as an example, the chlorine content in the organic wastewater is 35mg / L. The organic wastewater is pressurized to 0.5MPa by the mud pump and then transported to the organic waste surge tank. After being compressed, it enters the gas interface of the spray gun; after the organic waste water and compressed air are mixed in the spray gun, they are sprayed into the high temperature area of the furnace, and the chlorine in the organic waste water reacts with mercury to form HgCl 2 , the generated HgCl 2 Enter the desulfurization and dust removal device with the flue gas.

[0032] The flue gas volume is 30m 3 / h coal-fired boiler, the concentration of Hg is 11.6μg / m 3 The chlorine content of coal chemical organic wastewater injected into the furnace is 35mg / L, the injection volume is 6.2L / h, and the temperature range of injection into the furnace is 970-1040°C. After testing, the removal efficiency of Hg in the flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com