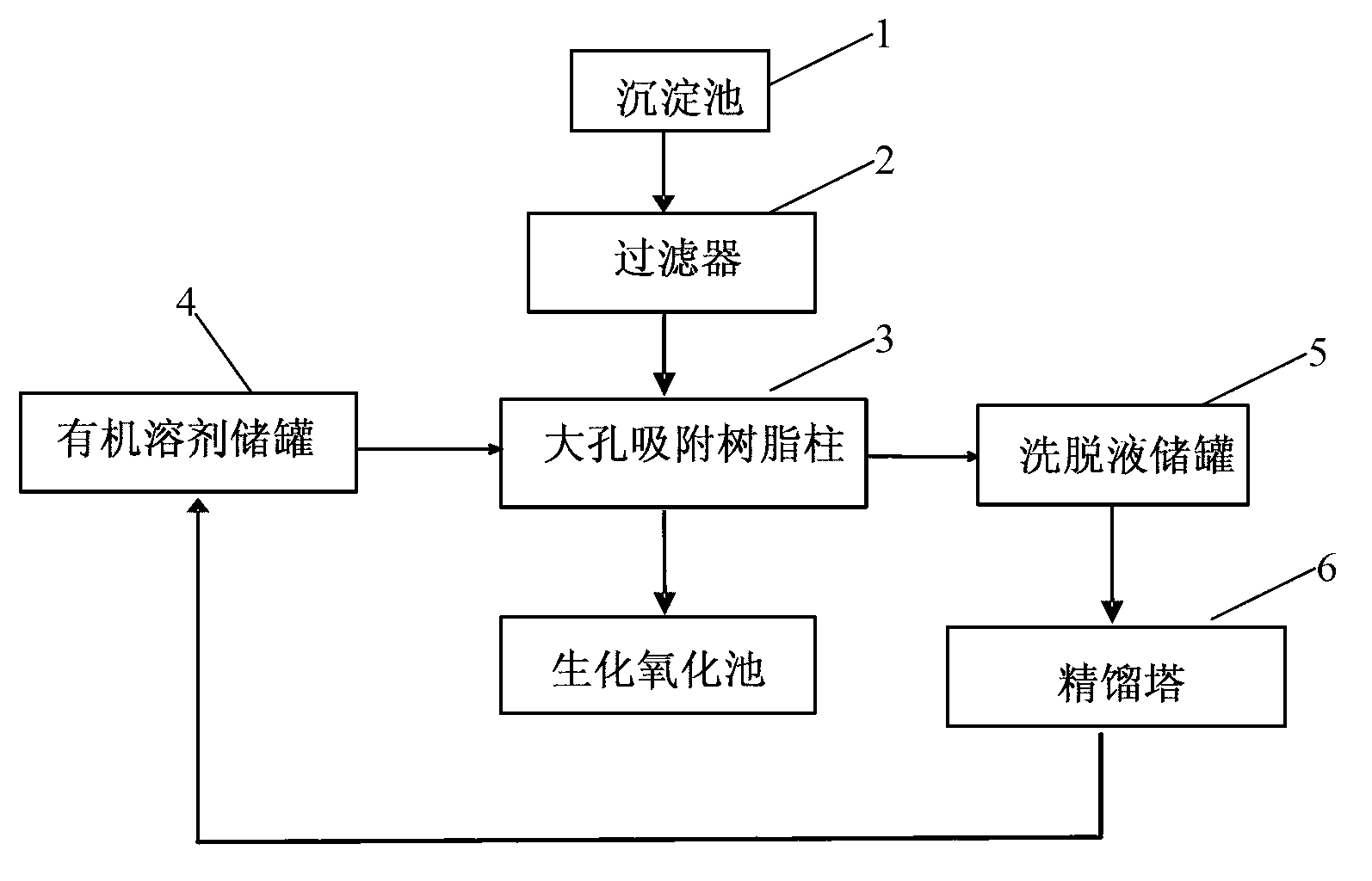

DNT (Dinitrotoluene) production wastewater recycling and treatment system and method

A technology for the production of wastewater and treatment methods, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high treatment cost, secondary pollution, carcinogenicity, etc., and achieve The effect of reducing CODcr, avoiding environmental pollution, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: certain factory is maroon to DNT production waste water, CODcr (chemical oxygen demand) is 3072mg / L, nitro compound 400mg / L.

[0027] 1.1 Put 60ml (1BV=60ml in this example) of LS-200 resin into the resin column (Φ20ⅹ300mm) fixed by iron clips, and put 800ml of wastewater that has been precipitated and filtered at 0°C at 30ml / h (0.5BV / h ) through the resin bed, the CODcr measured in the column liquid is less than 500mg / L, and no nitro compounds are detected;

[0028] 1.2 Rinse the resin with 120ml of water at about 25-30°C to remove the residual DNT and inorganic salts in the resin pores;

[0029] 1.3 Drain the resin column until the liquid does not flow out, use 120ml (2BV) industrial methanol solution at 5°C to elute the resin at a rate of 30ml / h (0.5BV / h), and collect all the desorption solution, 120ml The content of nitro compounds in the eluent is 0.25%, equivalent to 0.30g of nitro compounds, and the comprehensive recovery rate is 93.7%;

[0030] 1...

Embodiment 2

[0032] The procedure is the same as in Example 1, but the waste water in step 2 is 180ml / h (3BV / h) through the resin bed, but after the adsorption is completed, the resin is rinsed with water at about 30°C, and after the desorption is completed, water at about 40°C is used for the resin Rinse, other conditions are constant, and its result is identical with embodiment 1.

Embodiment 3

[0034] The steps are the same as in Example 1, but the resin in step 1.1 is changed to Amberlite XDA-7 resin, 240ml (4BV) is used as the desorption solution, and the desorption is carried out at a flow rate of 120ml / L (2BV / h), and other conditions remain unchanged, except that each batch Except that the secondary treatment capacity has change, its result is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com