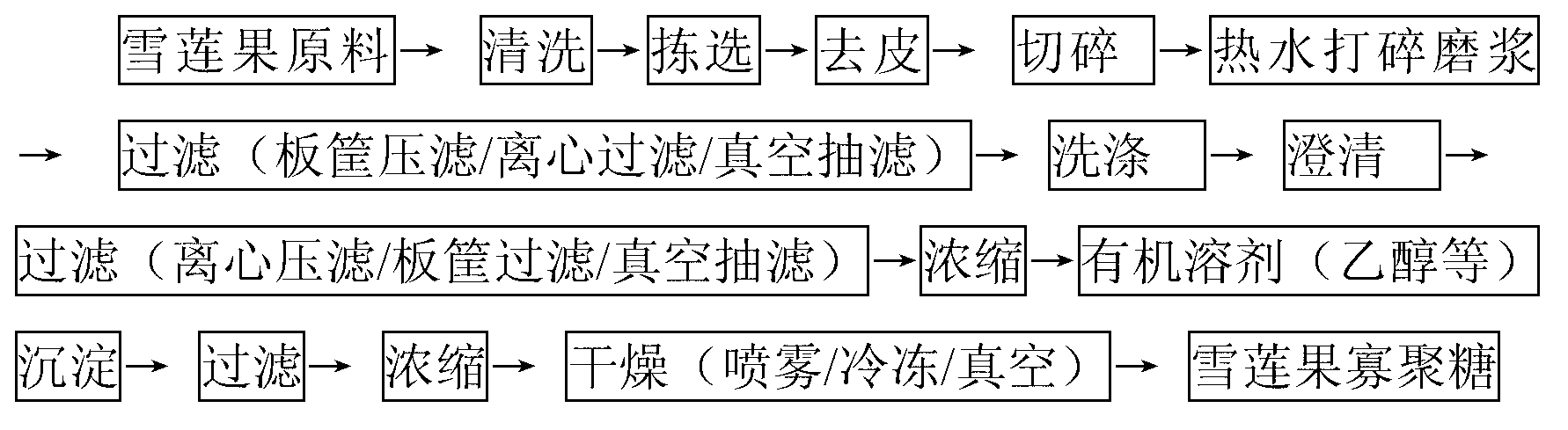

Production method of smallanthus sonchifolius oligosaccharide

A production method and technology of yacon, applied in the direction of oligosaccharides, sugar derivatives, sugar derivatives, etc., can solve the problems of unfavorable application and development of yacon oligosaccharides, harsh conditions, and difficult purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take fresh yacon fruit tubers, remove moldy and rotten fruits, wash with water, dry the water, weigh 2000g, peel off the skin, chop into fine pieces, immediately add 2000mL deionized water heated to 90°C, beat and grind crushed, filtered, and washed pomace twice with 500mL deionized water, discarded the filter residue, and combined the filtrate to obtain 4000mL of turbid viscous extract, heated to 50°C, stirred slowly and added 300mL of 1% weight concentration shell prepared in advance Polysaccharide solution, continue to stir and keep warm for 30min, cool, stand for 3 hours, filter to remove the precipitate, and obtain a light yellow clear extract, heat to 50°C, concentrate and recover to 300mL under reduced pressure to -0.08MPa, stir and add 1500mL of ethanol, Place it for clarification for 6 hours, filter to remove the precipitate, and obtain an ethanol extraction solution, heat to 40° C., concentrate and recover to dryness under reduced pressure to -0.08MPa, and obta...

Embodiment 2

[0024] Take fresh yacon fruit tubers, remove moldy and rotten fruits, wash with water, dry the water, weigh 2000g, peel off the outer skin, chop into fine pieces, add 2000mL of distilled water heated to 85°C, grind and beat, Press filter, wash the pomace twice with 500mL distilled water, discard the filter residue, and combine the filtrate to obtain 4000mL of turbid viscous yacon extract, heat to 80°C, stir and slowly add 200mL of prepared 1% weight concentration ZTC1+1II Type clarifier B solution, continue to stir and keep warm for 1 hour, then slowly add 100mL prepared 1% weight concentration ZTC1+1II type clarifier A solution, continue to keep warm and stir for 15 minutes, stop stirring, cool, place for 10 hours, suck out the supernatant The lower precipitate was centrifugally filtered, the filtrate was combined with the supernatant, decompressed to -0.08MPa, heated to 60°C, concentrated in vacuo and recovered to 300mL, stirred and added 1200mL of ethanol, left to clarify fo...

Embodiment 3

[0026] Take fresh yacon fruit tubers, remove moldy and rotten fruits, rinse with clean water, dry the outer skin, weigh 1000g, peel off the outer skin, chop into fine pieces, immediately add 1000mL of distilled water heated to 80°C, grind Finely beat the pulp, filter, and wash the pomace with 300mL distilled water for 2 times, discard the filter residue, and combine the filtrate to obtain 2000mL of turbid viscous yacon fruit extract, heat to 60°C, stir slowly and add 120mL of prepared 1% weight concentration 101 Juice clarifier A solution, continue to stir and keep warm for 1 hour, then slowly add 60mL of prepared 1% weight concentration 101 juice clarifier B solution, continue to keep warm and stir for 20 minutes, stop stirring, cool, place for 8 hours, extract the supernatant, The lower precipitate was centrifuged and filtered to remove the precipitate, the filtrate and the supernatant were combined, heated to 40°C, decompressed to -0.08MPa, concentrated in vacuo and recovere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com