Method for preparing synthetic hydrocarbon containing aromatic hydrocarbon from internal olefin

A technology for the synthesis of internal olefins and hydrocarbons, applied in the field of synthetic hydrocarbons, can solve the problems of large equipment investment and high energy consumption, and achieve the effects of small investment, easy industrialization, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

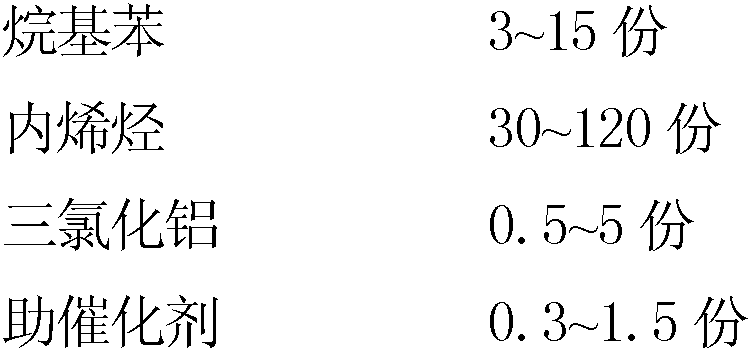

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of co-catalyst:

[0029] Under the condition of 30-50°C, mix 10 parts of conductive polyaniline and 75 parts of N-methylpyrrolidone, then add 12 parts of ammonia water and stir for 2 hours to obtain a cocatalyst.

[0030] 2. Preparation of synthetic hydrocarbons containing aromatics:

[0031] Using 35 parts of tetrapropylene (carbon twelve) and 10 parts of dodecylbenzene as raw materials, carry out alkylation reaction under the action of aluminum trichloride catalyst (1.5 parts) and cocatalyst (0.6 parts), alkylation The reaction is carried out under a nitrogen atmosphere, and the nitrogen pressure is 2 to 2.5kg / cm 2 , the reaction temperature is 25-30°C, and the reaction time is 6 hours. After the alkylation reaction, wash and neutralize with water, and after the pH value becomes neutral, distill and dehydrate under reduced pressure at 80°C, then refine and filter to obtain synthetic hydrocarbons containing aromatics.

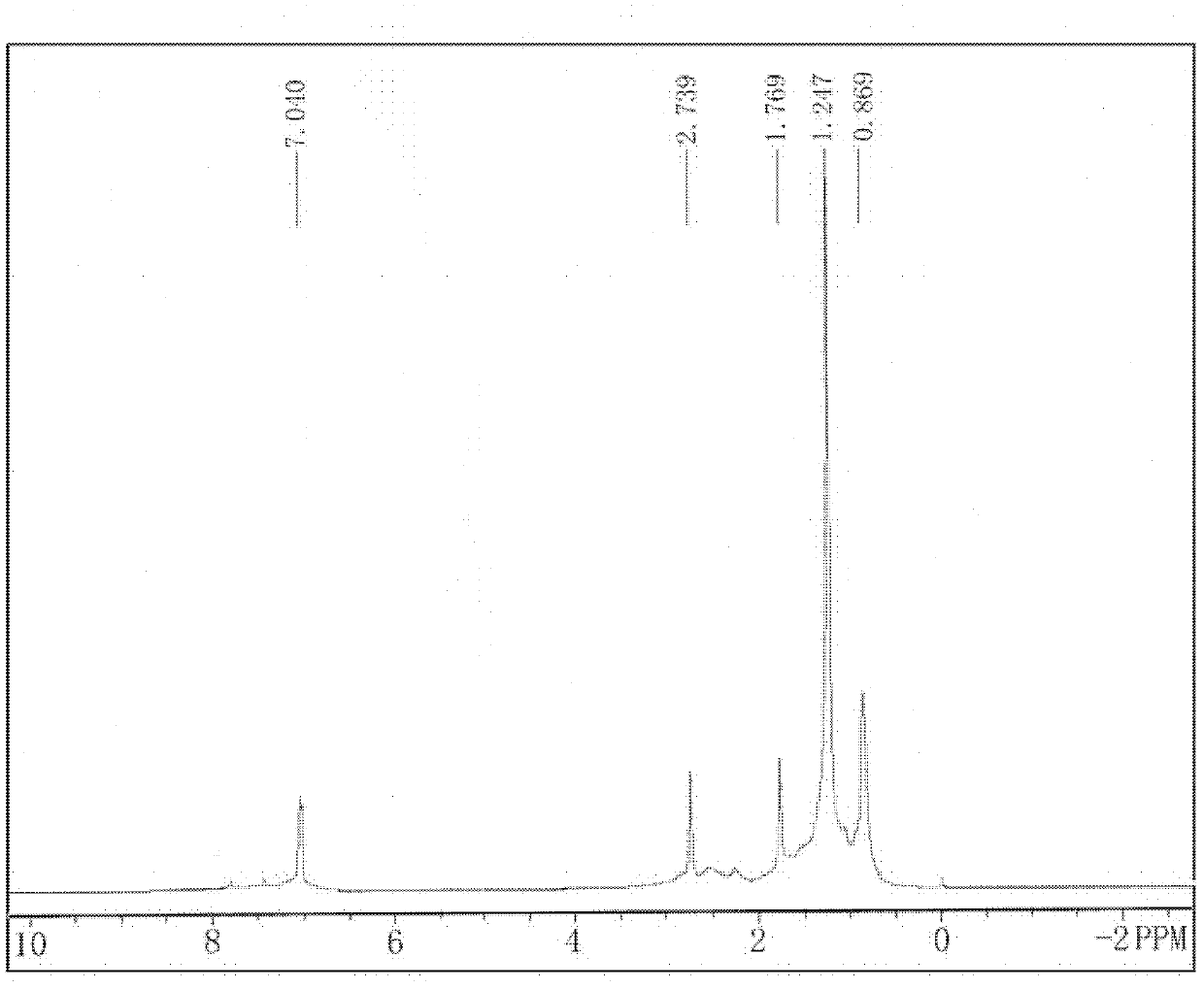

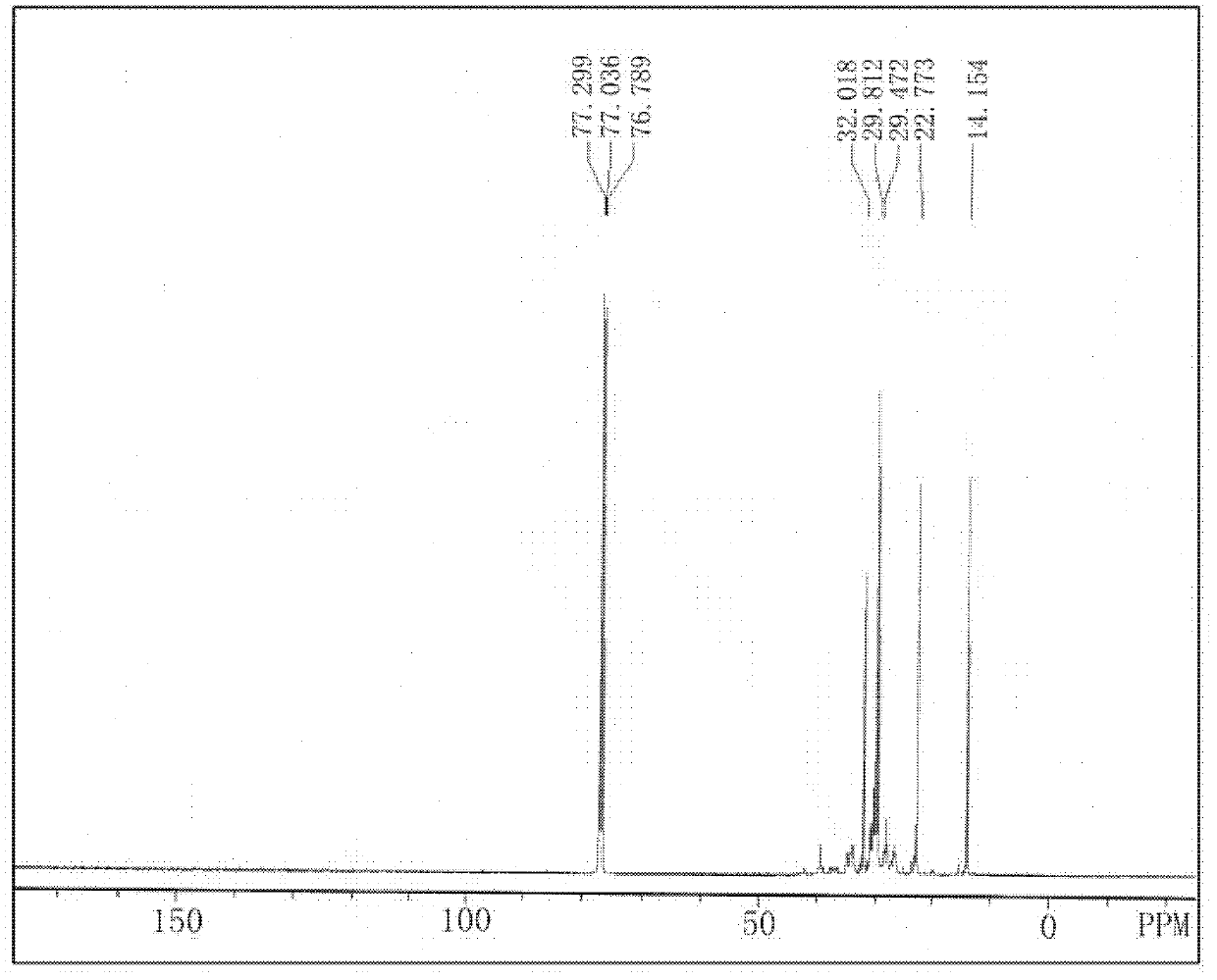

[0032] 3. Properties of aromati...

Embodiment 2

[0034] 1, the preparation of promoter: with embodiment 1.

[0035] 2. Preparation of synthetic hydrocarbons containing aromatics:

[0036] Using 35 parts of internal olefin carbon twelve and 10 parts of dodecylbenzene as raw materials, carry out the alkylation reaction under the action of aluminum trichloride catalyst (1.5 parts) and cocatalyst (0.6 part), and the alkylation reaction is carried out under nitrogen Carry out under atmosphere, nitrogen pressure 2~2.5kg / cm 2 , the reaction temperature is 25-30°C, and the reaction time is 6 hours. After the alkylation reaction, wash and neutralize with water, and after the pH value becomes neutral, distill and dehydrate under reduced pressure at 80°C, then refine and filter to obtain synthetic hydrocarbons containing aromatics.

[0037] 3. Properties of aromatic hydrocarbon-containing synthetic hydrocarbons in this embodiment: pour point: -40 degrees, flash point: 252 degrees, kinematic viscosity: 100 degrees 23, viscosity index:...

Embodiment 3

[0039] 1. Preparation of co-catalyst:

[0040] Under the condition of 30-50°C, 11 parts of conductive polyaniline and 70 parts of N-methylpyrrolidone were mixed, and then 14 parts of ammonia water was added and stirred for 3.5 hours to obtain a cocatalyst.

[0041] 2. Preparation of synthetic hydrocarbons containing aromatics:

[0042] Using 50 parts of tetrapropylene (carbon twelve) and 5 parts of dodecylbenzene as raw materials, carry out alkylation reaction under the action of aluminum trichloride catalyst (1.6 parts) and cocatalyst (0.7 parts), alkylation The reaction is carried out under a nitrogen atmosphere, and the nitrogen pressure is 2 to 2.5kg / cm 2 , the reaction temperature is 25-30° C., and the reaction time is 5 hours. After the alkylation reaction, wash and neutralize with water, and after the pH value becomes neutral, distill and dehydrate under reduced pressure at 80°C, then refine and filter to obtain synthetic hydrocarbons containing aromatics. Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com