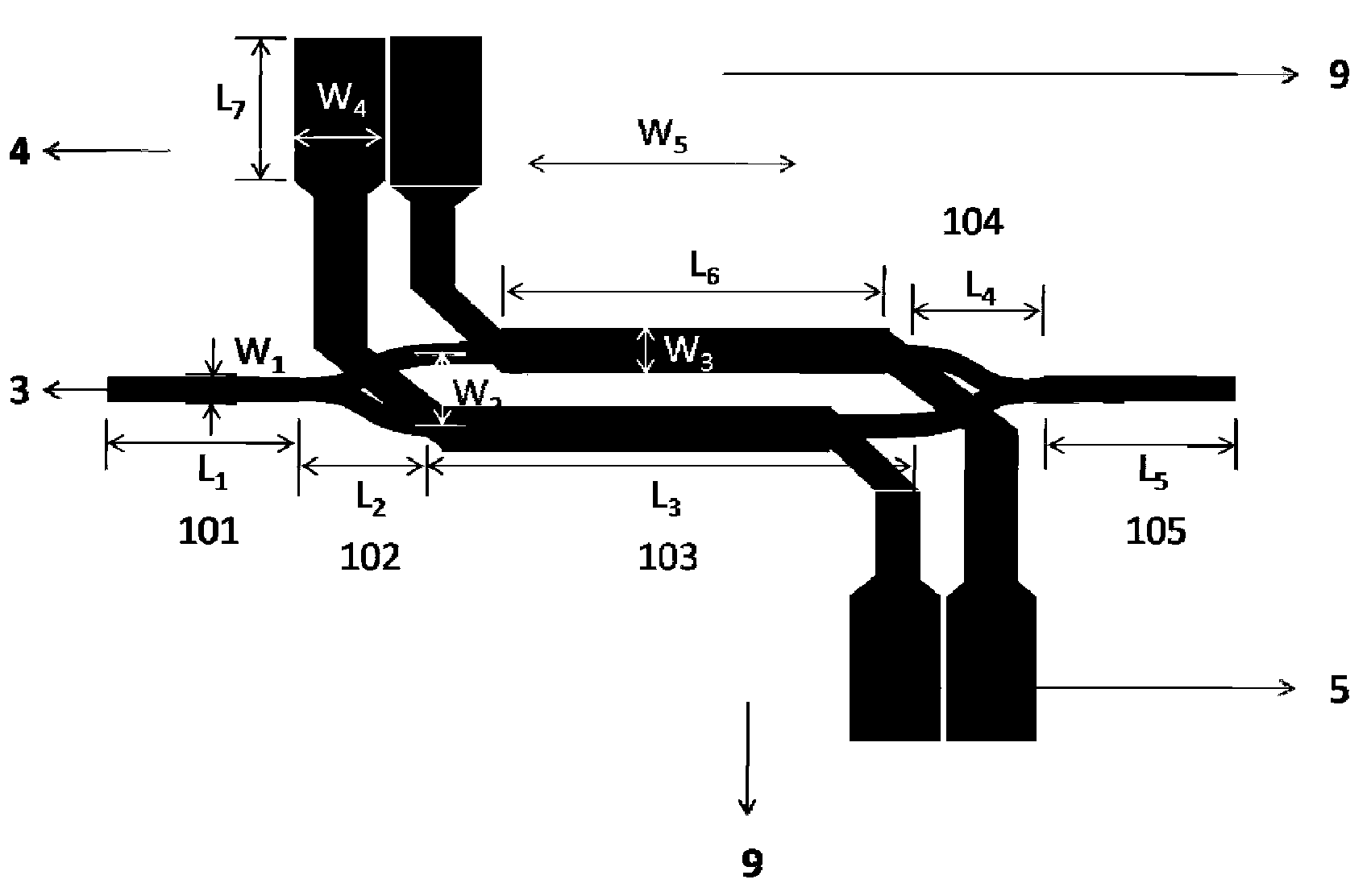

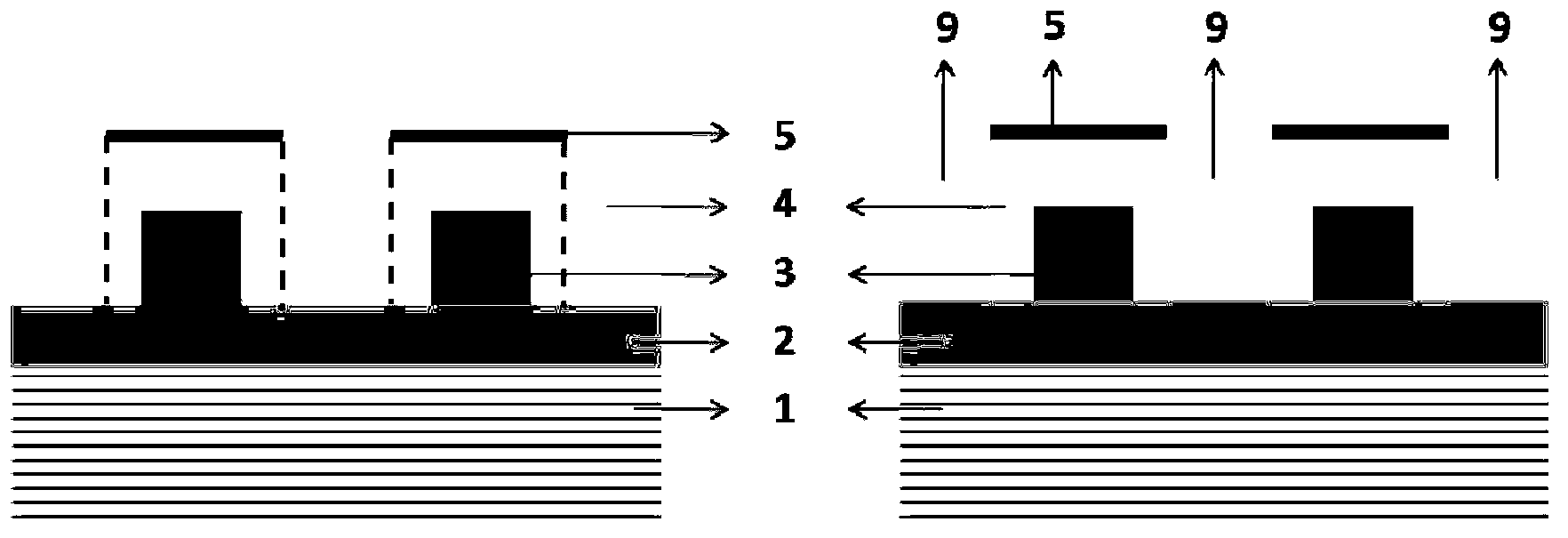

Low-power-consumption polymer thermo-optical switch with air isolating groove structure and manufacturing method of low-power-consumption polymer thermo-optical switch

An air isolation, thermo-optic switch technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of reduced electrode width and small development space, and achieve the effect of reducing power consumption, low cost, and advantages of power consumption performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

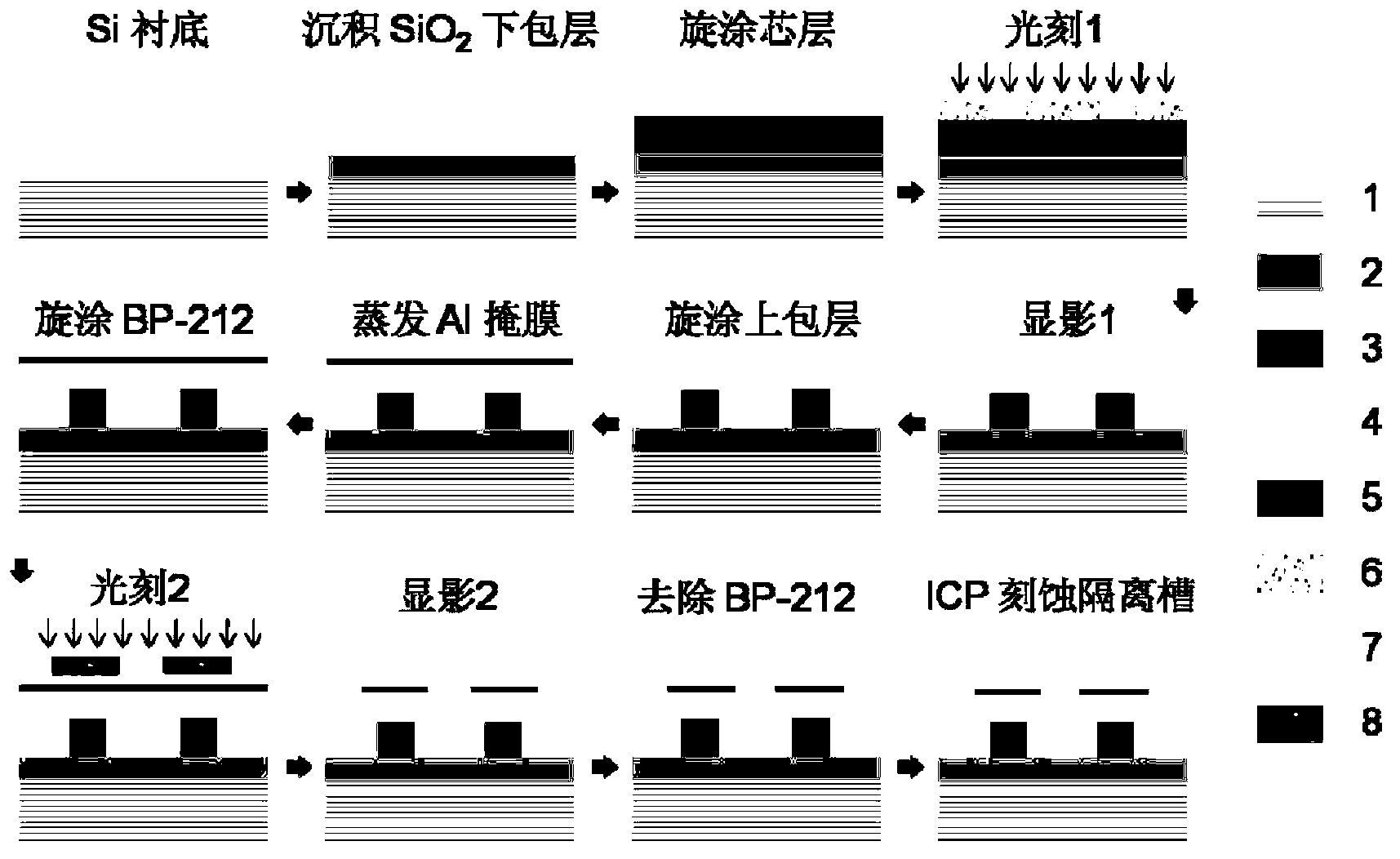

[0050] Example 1. Etching the air isolation groove structure to prepare a low-power polymer thermo-optic switch

[0051] Preparation of core layer (3) material: the preparation process is carried out under sodium yellow light environment. Drop 4.2 grams of SU-82005 into a weighing bottle, then drop 0.8 grams of SU-82005 special diluent into the same weighing bottle, and stopper to prevent volatilization. Stir magnetically for 12 hours to mix SU-82005 and its diluent evenly.

[0052] Preparation of materials for the upper cladding (4): Add 50 grams of methyl methacrylate, 7 grams of glycidyl methacrylate, 0.1 grams of Azobisisobutyronitrile and 150 milliliters of butyl acetate were heated and reacted in a water bath at 75°C for 4 hours, diluted with butyl acetate, filtered through a tetrafluoroethylene membrane with a pore size of 1 micron, and then distilled under reduced pressure to obtain A solution of a copolymer of methyl methacrylate and glycidyl methacrylate (as shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com