Method for manufacturing transient voltage suppressor by aid of ultra-deep trench structures

A transient voltage suppression, deep trench technology, used in semiconductor/solid state device manufacturing, circuits, electrical components, etc., can solve problems such as the inability to meet the increasing requirements of size and energy-saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0053] Our invention is a process method of using an ultra-deep trench (greater than 10 μm) structure to manufacture small-sized, ultra-low leakage current TVS diodes. Its process includes:

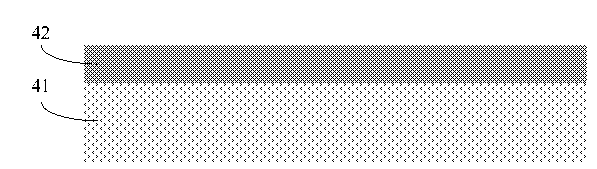

[0054] Step A: grow a layer of 5-15 μm heavily doped N-type epitaxial layer (Epitaxial Layer) 42 on the heavily doped P-type silicon substrate 41 ( image 3 ).

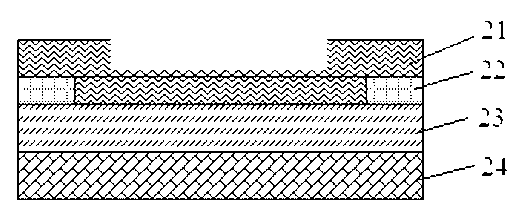

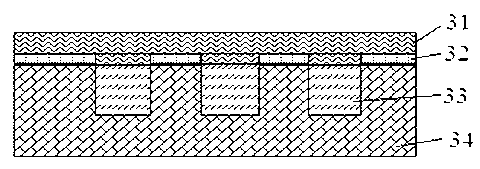

[0055] Step B: growing a layer of 10-30 μm near intrinsic lightly doped N-type epitaxial layer 43 on the heavily doped N-type epitaxial layer 42 ( Figure 4 ).

[0056] Step C: P-type region ion implantation.

[0057] Wherein, step C includes the following sub-steps:

[0058] Step C1: using a ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com