Single tube IGBT encapsulation full-bridge module and encapsulation method thereof

A single-tube and pin-based technology, applied in the field of single-tube IGBT package modules, can solve the problems of small thermal conductivity of insulating and thermally conductive silicone sheets, affecting work efficiency, and small heat dissipation area of the module, so as to improve work efficiency and service life, optimize external structure, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

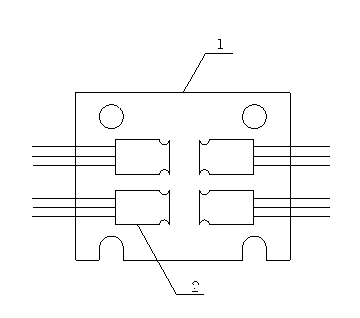

[0050] Step 1, evenly print solder paste with a thickness of 0.3 mm on the oxygen-free copper heat-conducting substrate 1 .

[0051] Step 2, fix the tooling tool on the oxygen-free copper heat-conducting substrate 1, and place the heat-conducting ceramic sheet at a fixed position through the position of the tooling tool.

[0052] Step 3, evenly apply 0.3mm thick solder paste on the thermally conductive ceramic sheet, and place 4 single-tube IGBT2 on the thermally conductive ceramic sheet. The single-tube IGBT2 can adopt the single-tube IGBT of the models IKW40N120, FGL60N100D, and FGL40N120.

[0053] Step 4: Fix the oxygen-free copper heat-conducting substrate 1, the heat-conducting ceramic sheet, and the four single-tube IGBTs 2 together with a fixing fixture and put them into a vacuum furnace.

[0054] Step 5: Evacuate the vacuum furnace to a vacuum state, gradually increase the temperature in the vacuum furnace to 170°C within 7 minutes, maintain for 3 minutes to fully mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com