Three-dimensional ordered noble metal nanotube array electrode and its preparation method

A nanotube array, three-dimensional ordered technology, applied in nanotechnology, nanotechnology, metal material coating technology and other directions, can solve the problems of unstable contact and poor electrical conductivity, and achieve uniform and orderly arrangement of array electrodes and electrical conductivity. High performance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 Gold nanorod short rod array electrode

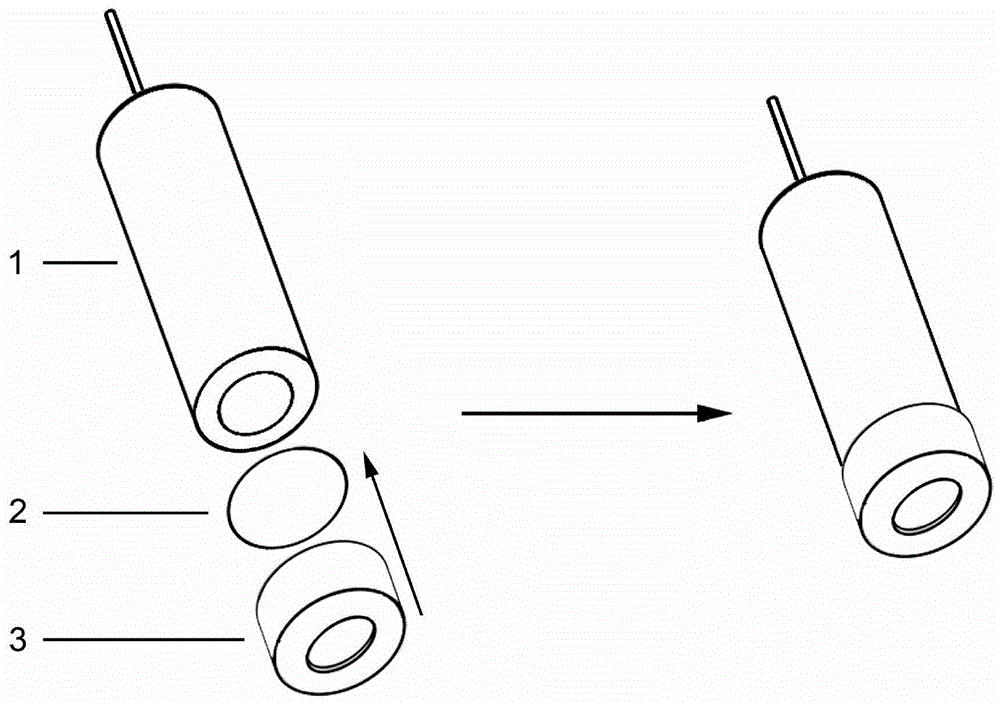

[0031] Step A) Fixing Porous Membrane

[0032] (1) Cleaning Cut the porous polycarbonate membrane as a template into a circle with a diameter of about 5 mm (such as figure 1 In 2), ultrasonically clean in ethanol for 5 minutes, and then ultrasonically clean in water three times for 5 minutes. Wherein, the specifications of the porous polycarbonate membrane are: the pore diameter is 400 nm, and the membrane thickness is 10 μm.

[0033] (2) Electrode pretreatment The gold disk electrode ( figure 1 1) Grinding and polishing the flocking sheet with W0.5 diamond abrasive paste, and then using Al with a particle size of 0.05 μm 2 o 3 Polish the suspension of suede, and then ultrasonically clean it in ethanol and three times in water for 3 minutes respectively, and set aside.

[0034] (3) Teflon cap for fixing ( figure 1 In 3) the polycarbonate porous membrane cleaned in step (1) ( figure 1 2) fixed on a gold electro...

Embodiment 2 3

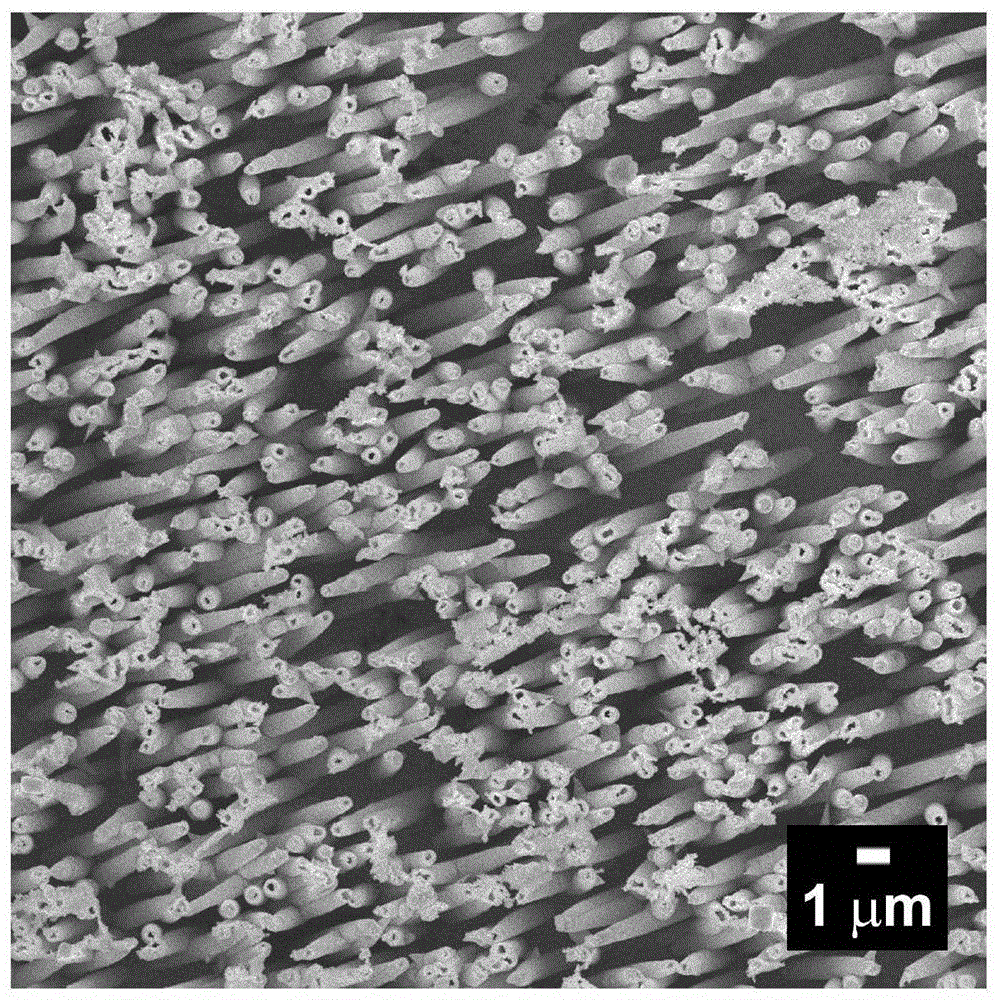

[0037] Example 2 Three-dimensional ordered pore wall gold nanotube array electrode

[0038] Fabrication of Gold Nanostub Rod Array Electrodes

[0039] Using the porous polycarbonate film as the template and the gold electrode as the flat base electrode, the gold nanorod short rod array electrode was prepared according to the electrochemical deposition method in Example 1. After the electrochemical deposition was completed, it was fully rinsed with water and absolute ethanol three times. Electrode, let dry.

[0040] Fabrication of three-dimensional ordered pore-walled gold nanotube array electrodes

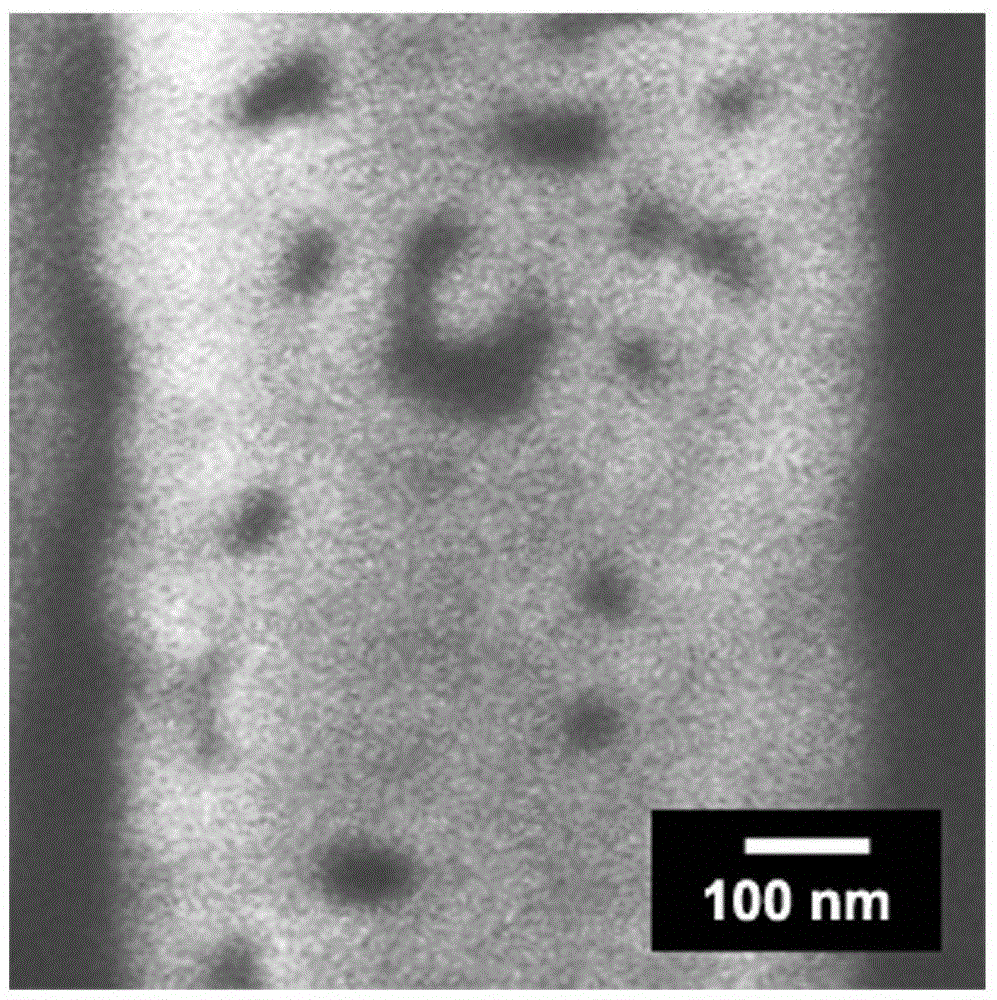

[0041] (1) Sensitization. Immerse the above-mentioned short gold nanorod array electrodes in SnCl 2 solution, the sensitizer Sn is adsorbed on the surface of the pore wall of the remaining channel part of the porous polycarbonate membrane 2+ At the same time, the surface of the porous membrane will also be adsorbed to a certain extent. The adsorption is maintained at room tempe...

Embodiment 3 3

[0046] Example 3 Three-dimensional ordered gold nanotube array electrode

[0047] 1. Fabrication of Titanium Nanoshort Rod Array Electrodes

[0048] Using the porous polycarbonate film as the template and the titanium electrode as the planar substrate electrode, prepare titanium nano-short rod array electrodes according to the electrochemical deposition method in Example 1, and rinse thoroughly with water and absolute ethanol three times after the electrochemical deposition is completed. Electrode, let dry.

[0049] 2. Preparation of three-dimensional ordered pore wall gold nanotube array electrodes

[0050] (1) Modification. The titanium nano short rod array electrode prepared in step 1 is immersed in (2-cyanoethyl) triethoxysilane solution, the pore wall surface of the remaining channel part of porous polycarbonate membrane is modified cyano group, simultaneously the porous membrane The surface will also be modified to a certain extent. The modification is kept at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com