Treatment method of gold extraction cyaniding wastewater containing copper and iron ions with high concentration

A waste water treatment, iron ion technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high equipment pressure, cyanide consumption, high cost, etc., and reduce the cost of enterprises Low cost, significant economic benefits, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

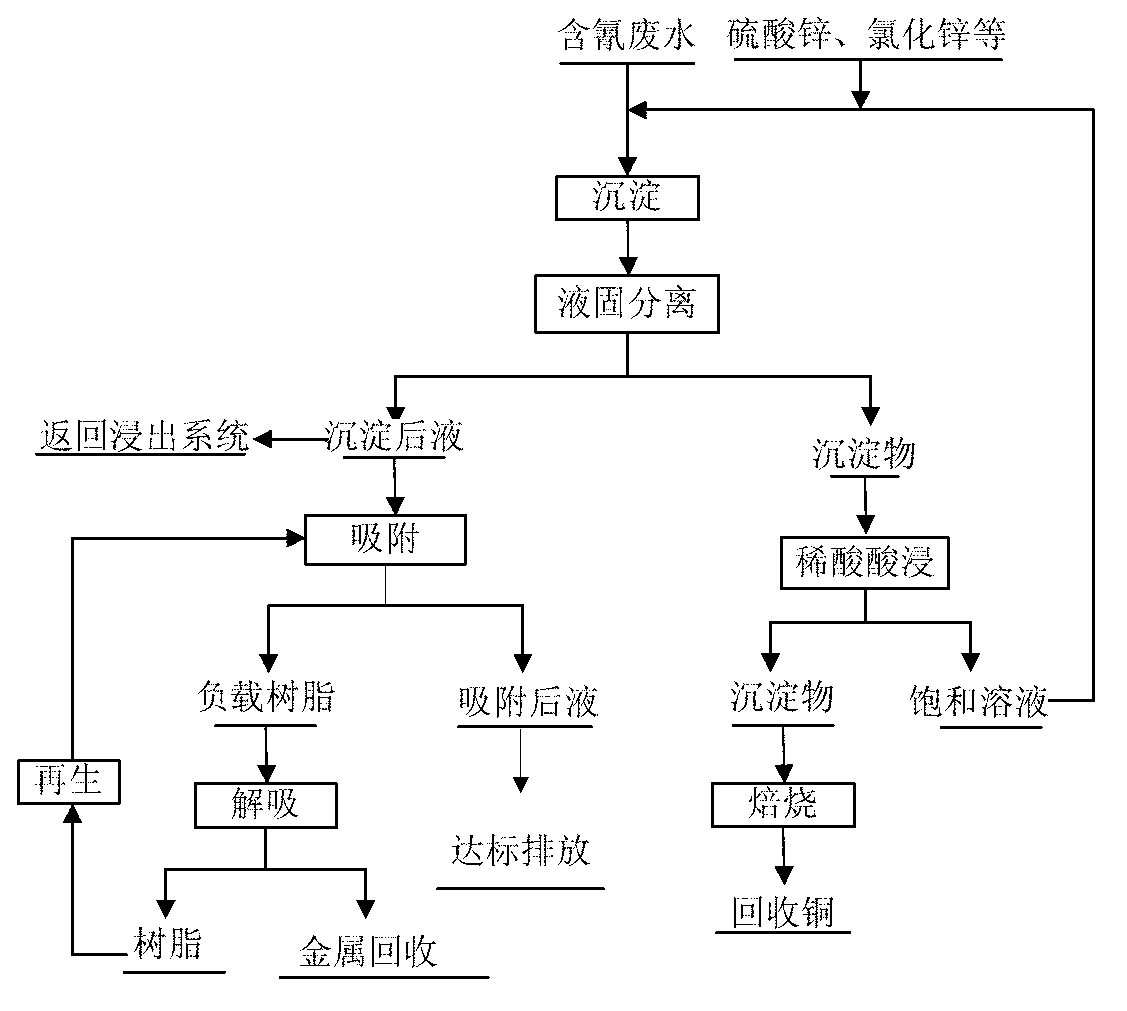

Method used

Image

Examples

Embodiment 1

[0051] The cyanide-containing wastewater in this example was taken from a 4# thickener in a gold smelter in Henan. The test results of the ion concentration in the wastewater before treatment are shown in Table 1.

[0052] The metal ion content of table 1 stoste

[0053] Metal ion species in wastewater CN - (mg / L) Cu(g / L) Fe(mg / L) Zn(mg / L) Au(mg / L) Ion concentration (mg / L) 760 4.5 62.9 249 0.34

[0054] The specific operation steps are as follows: take 100ml of waste water and put them into six 200ml beakers respectively, add different amounts of zinc sulfate and stir for 1 hour, filter and take the clear liquid and measure the results as follows:

[0055] Table 2. ZnSO 4 Experimental results with addition of on-site wastewater

[0056] The amount of zinc sulfate added (g / 100ml) 0.5 1.5 2.0 3.0 3.5 4.0 Residual copper content in wastewater (g / L) 3.44 1.52 1.13 0.38 0.12 0.04 Amount of remaining gold in wastew...

Embodiment 2

[0066] The wastewater in this example comes from the wastewater of a gold smelter, and the concentration of metal ions before wastewater treatment is shown in Table 4.

[0067] The ion content of table 4 stoste

[0068] Metal ion species in wastewater CN - (mg / L) Cu(g / L) Fe(mg / L) Zn(mg / L) Au(mg / L) Ion concentration (mg / L) 920 2.58 740 1180 0.31

[0069] The operation steps are as follows: each get 100ml waste water and pack into 6 200ml beakers respectively, add different amounts of zinc chloride and stir for 1h, filter and get the clear liquid and measure the results as follows:

[0070] Table 5. Experimental results of adding zinc chloride to field wastewater

[0071] The amount of zinc chloride added (g / 100ml) 1.0 1.5 2.0 2.5 3.0 4.0 Residual copper content in wastewater (g / L) 1.98 1.32 0.75 0.36 0.17 0.021 Amount of remaining gold in wastewater (g / m3) 0.31 0.30 0.32 0.30 0.31 0.31

[0072] It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com