Ultra nanometer silver ion zirconium silicate ceramic artwork and preparation method thereof

A ceramic handicraft, zirconium silicate technology, applied in the field of ceramic products, can solve the problems of fragility, low yield, poor fracture toughness, etc., to achieve the effect of enhancing strength and fracture toughness, and strengthening antibacterial efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

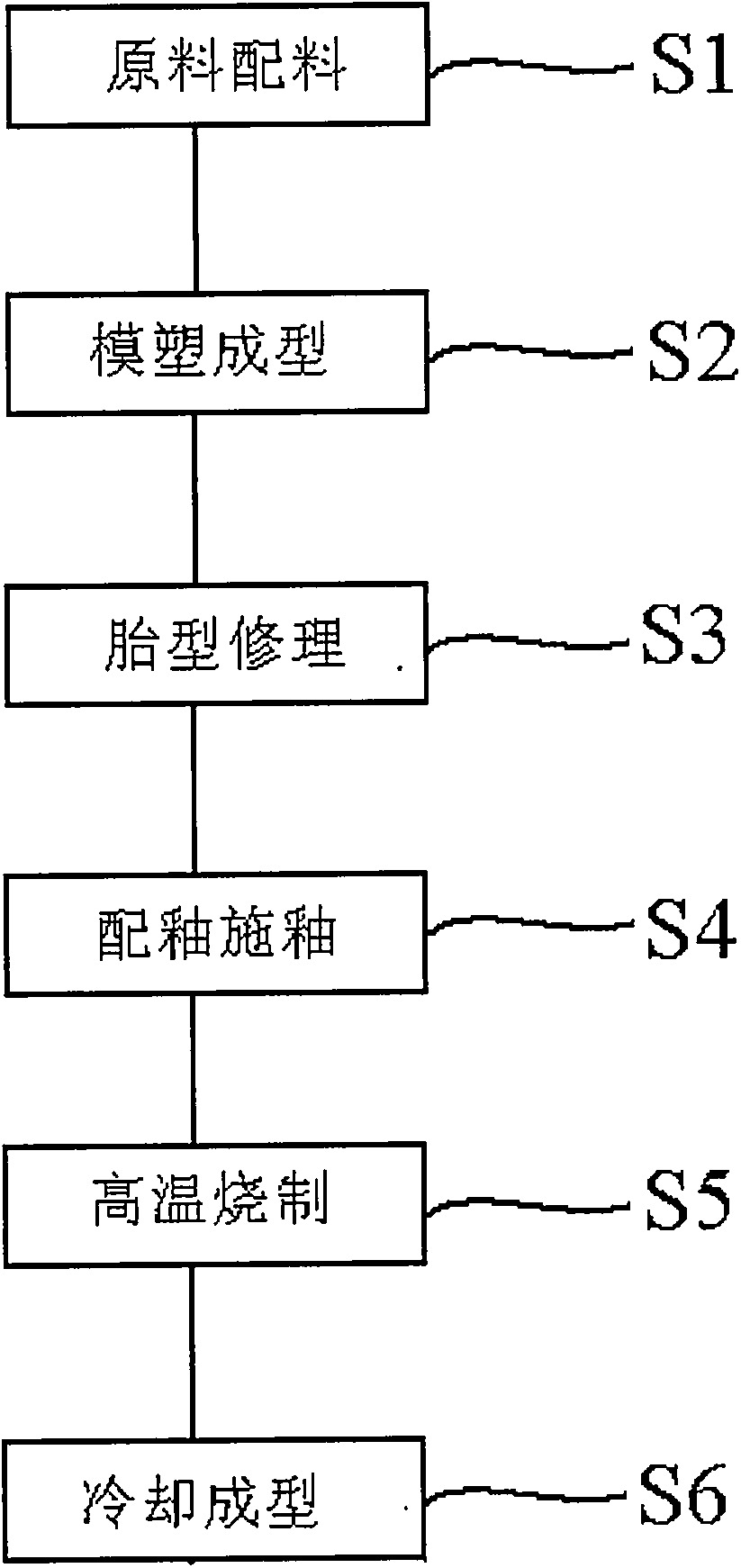

[0036] refer to figure 1 As shown, the preparation method of the ultra-nano silver ion zirconium silicate ceramic handicraft of the present embodiment comprises the following steps:

[0037] S1 Raw material ingredients: Accurately weigh the following ceramic body raw materials by weight, 30 parts of kaolin, 40 parts of quartz, 10 parts of zirconium silicate, 10 parts of feldspar, 5 parts of Muyu stone powder, 5 parts of talc, 5 parts of neodymium oxide, and Mixing, crushing, grinding, and sieving to obtain the mixed raw material, wherein the fineness of the mixed raw material is to pass through a 120-mesh sieve;

[0038] S2 Molding: Molding the above-mentioned mixed raw materials, and drying to 15-18% moisture to obtain green billets;

[0039] S3 tire type repair: Use tools to trim and smooth the green billet;

[0040] S4 glaze glazing: Accurately weigh the following glaze layer raw materials by weight, 20 parts of quartz, 45 parts of feldspar, 1 part of nano silver-loaded a...

Embodiment 2

[0047] The difference between this embodiment and Example 1 is: the raw material of the ceramic body is 40 parts of kaolin, 45 parts of quartz, 5 parts of zirconium silicate, 5 parts of feldspar, 3 parts of wood fish stone powder, 5 parts of talc, and 3 parts of cerium oxide. And mix, pulverize, grind, sieve to get the mixed raw material;

[0048] The raw materials of the glaze layer are 15 parts of quartz, 35 parts of feldspar, 2 parts of nano silver-loaded antibacterial agent, 5 parts of talc, 2 parts of zinc oxide, 2 parts of tin oxide, 2 parts of copper oxide and 5 parts of cerium oxide.

Embodiment 3

[0050] The difference between this embodiment and Embodiment 1 is that the rare earth in the raw material of the ceramic body and the glaze layer is a mixture of neodymium oxide and praseodymium oxide, and the mixing ratio is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com