Core-shell structural elastic emulsion, coating containing emulsion and preparation method thereof

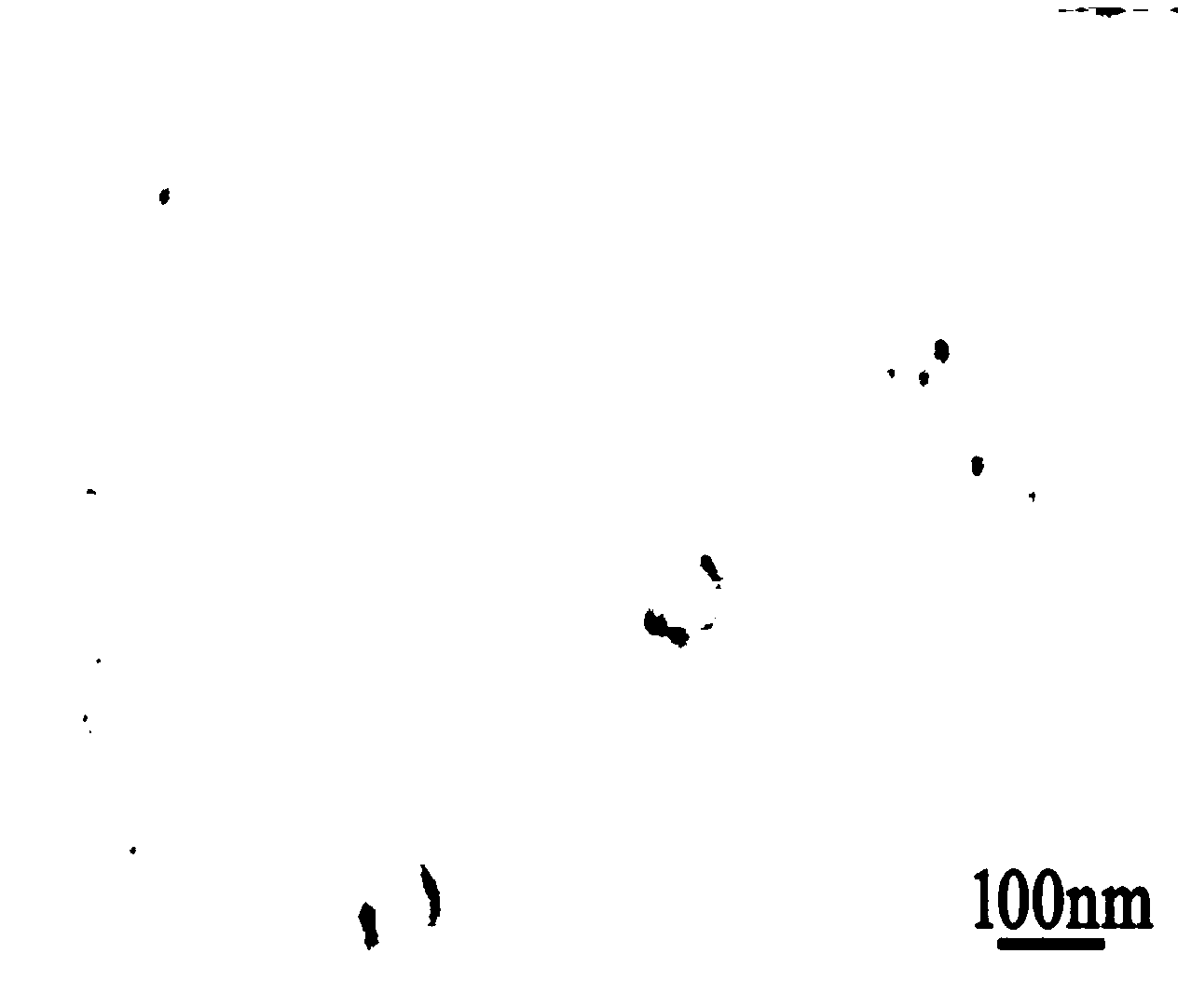

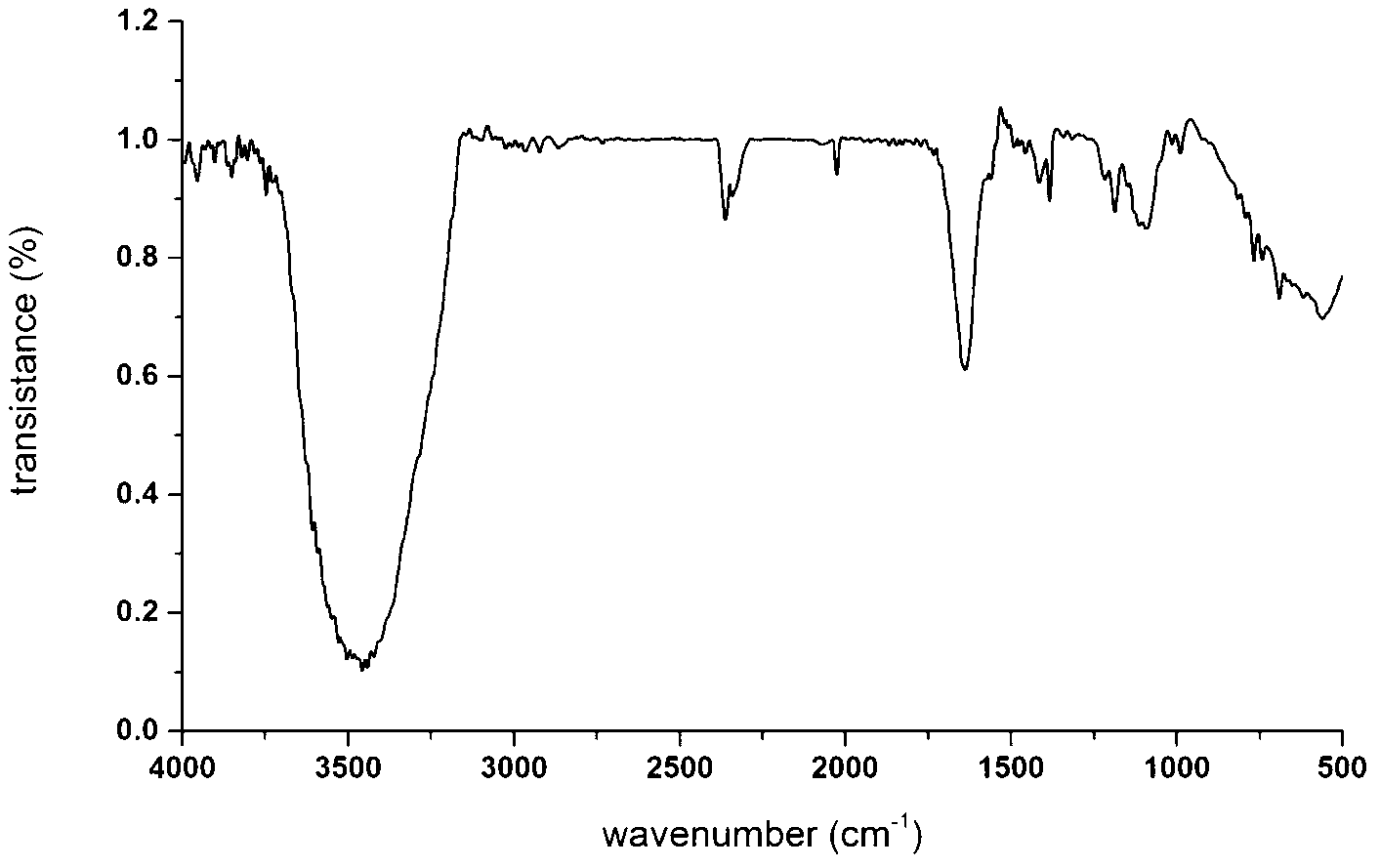

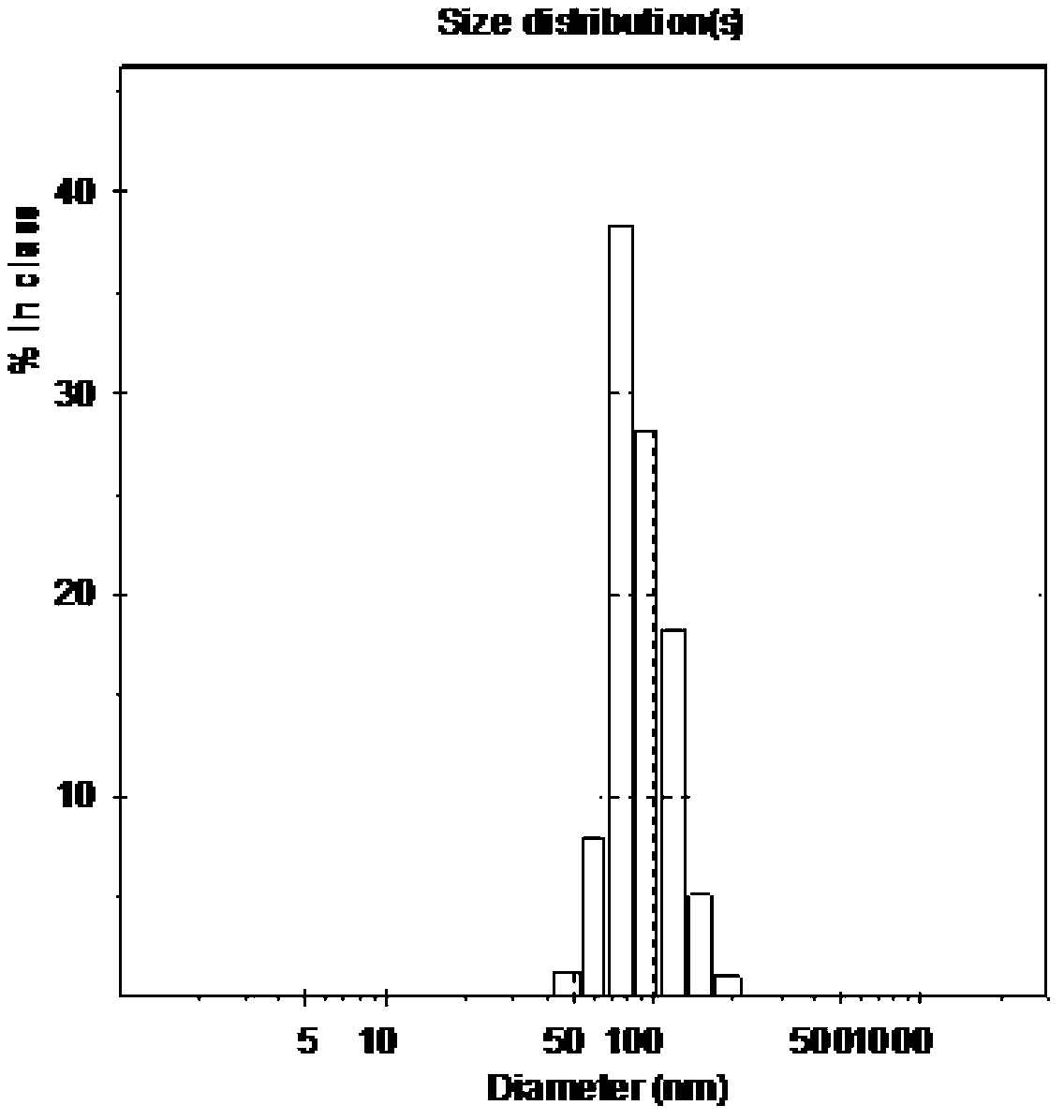

An elastic emulsion, core-shell type technology, applied in coatings containing core-shell type elastic emulsion and its preparation, in the field of core-shell type elastic emulsion, can solve the problems of poor dimensional stability, limited application, low glass transition temperature, etc., and achieve excellent Good elasticity, emulsion stability, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: A preparation of a coating containing a core-shell elastic emulsion, the steps are as follows: 1. Preparation of poly(butyl acrylate-styrene) / polymethyl methacrylate core-shell emulsion

[0030] a. Preparation of poly(butyl acrylate-styrene) seed emulsion

[0031] Weigh 3.6g of butyl acrylate (BA), 0.96g of styrene (St), 0.072g of sodium dodecyl sulfate (SDS), 0.096g of OP-100, 0.048g of ethylene glycol dimethacrylate (EDMA), Put 0.072g of propyl methacrylate (ALMA) and 24g of deionized water in a four-neck flask. Raise the temperature to 80°C and stir for 20min. Weigh 0.144 g of the initiator potassium persulfate (KPS) into the flask, and stir for 15 min to obtain the seed emulsion.

[0032] b. Diameter expansion of poly(butyl acrylate-styrene) seed emulsion

[0033] According to the equal proportion of the preparation formula of the seed emulsion in step a, the proportion is enlarged by 8 times, and butyl acrylate, styrene, sodium lauryl sulfate, OP-10, ...

Embodiment 2

[0054] Embodiment 2: the preparation of a kind of coating that contains core-shell type elastic emulsion, the steps are as follows:

[0055] ① Preparation of poly(butyl acrylate-styrene) / polymethyl methacrylate core-shell emulsion

[0056] a. Preparation of poly(butyl acrylate-styrene) seed emulsion

[0057] Weigh 4.8g of butyl acrylate (BA), 0.72g of styrene (St), 0.024g of sodium dodecyl sulfate (SDS), 0.12g of OP-100, 0.072g of ethylene glycol dimethacrylate (EDMA), Put 0.024g of propyl methacrylate (ALMA) and 24g of deionized water in a four-neck flask. Raise the temperature to 80°C and stir for 20min. Weigh 0.168 g of initiator potassium persulfate (KPS) into the flask, stir for 15 min to obtain seed emulsion.

[0058] b. Diameter expansion of poly(butyl acrylate-styrene) seed emulsion

[0059] According to the preparation formula of the seed emulsion in step a, the equal ratio is enlarged by 9 times. Prepare a pre-emulsion with butyl acrylate, styrene, sodium lauryl...

Embodiment 3

[0080] Embodiment 3: the preparation of a kind of coating that contains core-shell type elastic emulsion, the steps are as follows:

[0081] ① Preparation of poly(butyl acrylate-styrene) / polymethyl methacrylate core-shell emulsion

[0082] a. Preparation of poly(butyl acrylate-styrene) seed emulsion

[0083] Weigh 6g of butyl acrylate (BA), 1.2g of styrene (St), 0.048g of sodium dodecyl sulfate (SDS), 0.144g of OP-100, 0.024g of ethylene glycol dimethacrylate (EDMA), and 0.048 g of propyl acrylate (ALMA) and 24 g of deionized water were placed in a four-necked flask. Raise the temperature to 80°C and stir for 20min. Weigh 0.192 g of the initiator potassium persulfate (KPS) and add it into the flask, and stir for 15 min to obtain the seed emulsion.

[0084] b. Diameter expansion of poly(butyl acrylate-styrene) seed emulsion

[0085] According to the preparation formula of the seed emulsion in step a, the preparation formula is enlarged by 10 times, and the pre-emulsion is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com