Production method of TPR shoe material surface treatment agent

A surface treatment agent and production method technology, applied in the field of surface treatment of rubber materials, can solve the problems of insufficient polarity, tensile force, insufficient oil resistance, etc., to improve heat resistance and yellowing resistance, increase polarity, The effect of improving monomer conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

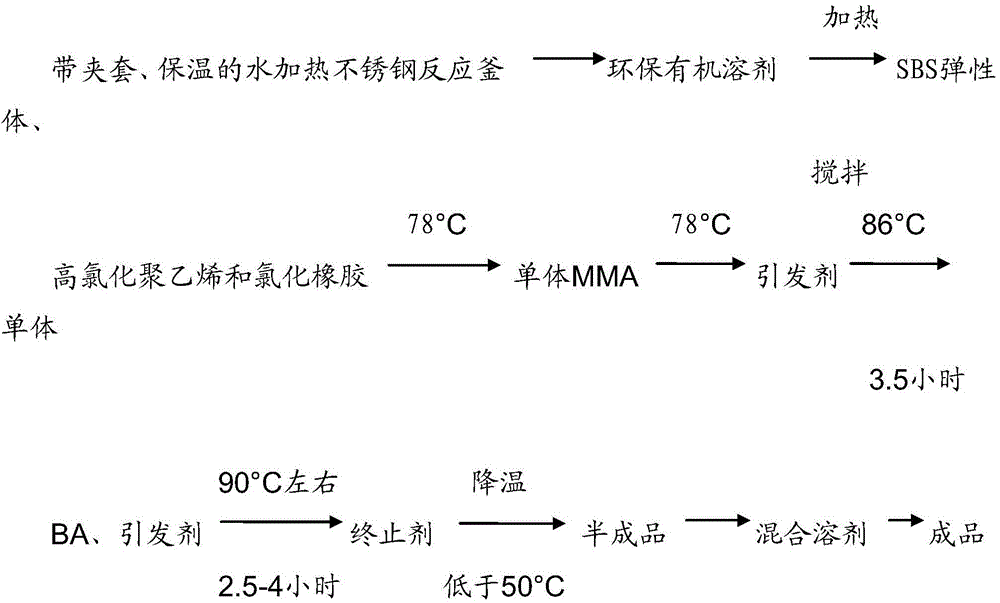

Embodiment 1

[0015] A method for producing TPR shoe material treatment agent, using a boiler or an electric heating tube to directly heat water to raise the temperature, first put an organic solvent into the reaction kettle, and put in under stirring 90 parts of SBS elastomer with a relative density of 0.90 and a relative density of 62 parts of high chlorinated polyethylene of 1.35, 5 parts of chlorinated rubber with a relative density of 1.5; and at the same time, the temperature of the system in the reactor was raised to 70°C. Add 80 parts of monomer MMA at 70°C. When the temperature in the reaction kettle rises to 70°C again, put in 3.2 parts of initiator, stir for 0.5-1 minute, then reduce the stirring speed to 30-50 rpm, raise the temperature to 86°C, and keep warm for 3.5 hours. After 3.5 hours of heat preservation reaction, add 15 parts of monomer BA and 0.8 parts of initiator under rapid stirring, and after stirring for 0.5-1 minute, reduce the stirring speed to 30-50 rpm, and rais...

Embodiment 2

[0016] Embodiment 2: A method for producing TPR shoe material treatment agent, using a boiler or an electric heating tube to directly heat water to raise the temperature, first put an organic solvent into the reaction kettle, and put 100 parts of SBS elastomer with a relative density of 0.91 under stirring ; 55 parts of high chlorinated polyethylene with a relative density of 1.4; 5 parts of chlorinated rubber with a relative density of 1.6; Add 85 parts of monomer MMA at 78°C. When the temperature in the reactor rises to 78°C again, put in 3.2 parts of initiator, stir for 0.5-1 minute, then reduce the stirring speed to 30-50 rpm, raise the temperature to 90°C and keep it warm for 4 hours. After 4 hours of heat preservation reaction, add 12 parts of monomer BA and 0.8 parts of initiator under rapid stirring, and after stirring for 0.5-1 minute, reduce the stirring speed to 30-50 rpm, and raise the temperature of the reaction system to 88°C and keep it warm reaction. After 2 ...

Embodiment 3

[0017] Example 3: A method for producing TPR shoe material treatment agent, using a boiler or an electric heating tube to directly heat water to raise the temperature, first put an organic solvent into the reaction kettle, and put in 110 parts of SBS elastomer with a relative density of 0.92 under stirring 65 parts of high-chlorinated polyethylene with a relative density of 1.45; 5 parts of chlorinated rubber with a relative density of 1.7; Add 90 parts of monomer MMA at 80°C. When the temperature in the reaction kettle rises to 80°C again, put in 3.2 parts of initiator, stir for 0.5-1 minute, then reduce the stirring speed to 30-50 rpm, raise the temperature to 80°C and keep it warm for 3 hours. After 3 hours of heat preservation reaction, add 17 parts of monomer BA and 0.8 parts of initiator under rapid stirring, and after stirring for 0.5-1 minute, reduce the stirring speed to 30-50 rpm, and raise the temperature of the reaction system to 90°C and keep it warm reaction. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com