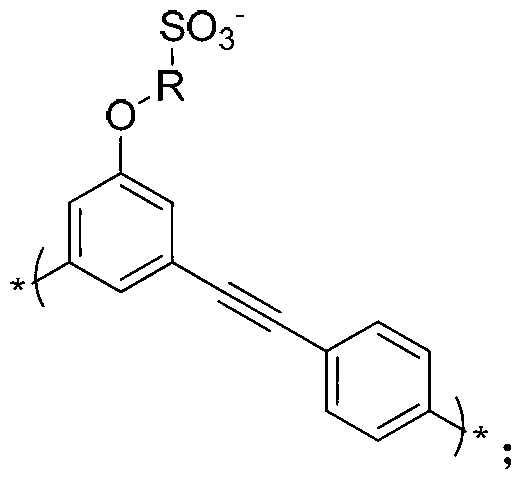

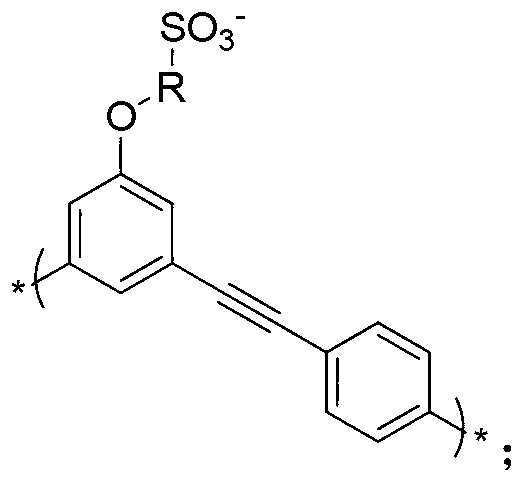

Novel polythiophene disperse system as well as preparation method and application thereof

A dispersion system and polythiophene technology, applied in the field of chemical materials, can solve the problems of not being able to produce in a large area, service life and stability need to be improved, and achieve good photoelectric effect, good water solubility and film-forming performance, conductivity and stability sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Mix 0.04 parts by mass of a main chain conjugated polyelectrolyte solution with a weight fraction of 5 wt % and 0.03 parts by mass of an aqueous solution of ferric chloride in a three-necked flask, fill with nitrogen, and stir at room temperature for 20 minutes. Then, a saturated aqueous solution containing 0.01 parts by mass of 3,4-ethyldioxythiophene was slowly added dropwise and stirred rapidly at room temperature for 72 hours. Then, the mixed liquid is purified with carboxylic acid cation exchange resin to obtain a blue transparent ink-like dispersion liquid, that is, a novel polythiophene dispersion system is prepared. The microcrystalline structure of poly-3,4-ethyldioxythiophene was studied by small-angle X-ray scattering (SAXS) and wide-angle X-ray scattering (WAXS), detected by dynamic light scattering (DLS), particle size distribution was 10-80nm.

[0047] The results show that there are Bragg scattering absorption peaks at 2θ=2.38° (d=3.7nm) and 2θ=5.46° (d=1...

Embodiment 2

[0049] 0.04 parts by mass of a main chain conjugated polyelectrolyte solution with a weight fraction of 6 wt% and 0.04 parts by mass of an aqueous solution of ferric chloride were mixed uniformly in a three-necked flask, protected with nitrogen, and stirred at room temperature for 20 minutes. Then, a saturated aqueous solution containing 0.01 parts by mass of 3,4-ethyldioxythiophene was slowly added dropwise and stirred rapidly at room temperature for 72 hours. Then, the mixed liquid is purified with carboxylic acid cation exchange resin to obtain a blue transparent ink-like dispersion liquid, that is, a novel polythiophene dispersion system is prepared. By dynamic light scattering (DLS) detection, highly oriented particles of 15-100 nm were obtained.

[0050] The obtained new polythiophene dispersion system was drop-coated on a glass substrate, degassed in vacuum for 5 minutes, then dehydrated in air at 50°C for 12 hours, and finally dried in vacuum for 2 hours to obtain a hi...

Embodiment 3

[0052] Mix 14 parts by mass of main chain conjugated polyelectrolyte with a weight fraction of 5 wt% aqueous solution and 3.3 parts by mass of ferric chloride aqueous solution in a three-necked flask, fill with nitrogen protection, and stir at room temperature for 30 minutes. Then, a saturated aqueous solution containing 1.00 parts by mass of 3,4-ethyldioxythiophene was slowly added dropwise and stirred rapidly at room temperature for 72 hours. Then, the mixed liquid is purified with carboxylic acid cation exchange resin to obtain a blue transparent ink-like dispersion liquid, that is, a novel polythiophene dispersion system is prepared. By dynamic light scattering (DLS) detection, highly oriented particles of 12-80 nm were obtained.

[0053] The obtained new polythiophene dispersion system was drop-coated on a glass substrate, degassed in vacuum for 5 minutes, then dehydrated in air at 50°C for 12 hours, and finally dried in vacuum for 2 hours to obtain a highly oriented mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com