Method for preparing reduced-oxidized graphene/Cu2O/Cu quantum dot ternary wave-absorbing material

A technology of wave absorbing materials and quantum dots, applied in chemical instruments and methods, nanotechnology for materials and surface science, and other chemical processes, etc. and other problems, to achieve the effect of good absorbing performance, simple preparation method and wide absorbing frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, according to the mass ratio GO: CuCl 2 ·2H 2 O=1: 0.66, weigh out 66mg CuCl 2 ·2H 2 O, add to 200ml GO aqueous solution, stir for 30min, ultrasonic for 30min;

[0025] 2. According to the mass ratio GO: NaBH 4 =1∶10, weigh out 1g NaBH 4 Dissolve in 50ml water, drip into the mixed solution, react for 3h at room temperature;

[0026] 3. The obtained black precipitate is washed twice with deionized water by centrifugal washing method, and dried under vacuum at 60℃. The obtained black powder is RGO / Cu 2 O / Cu ternary composite material.

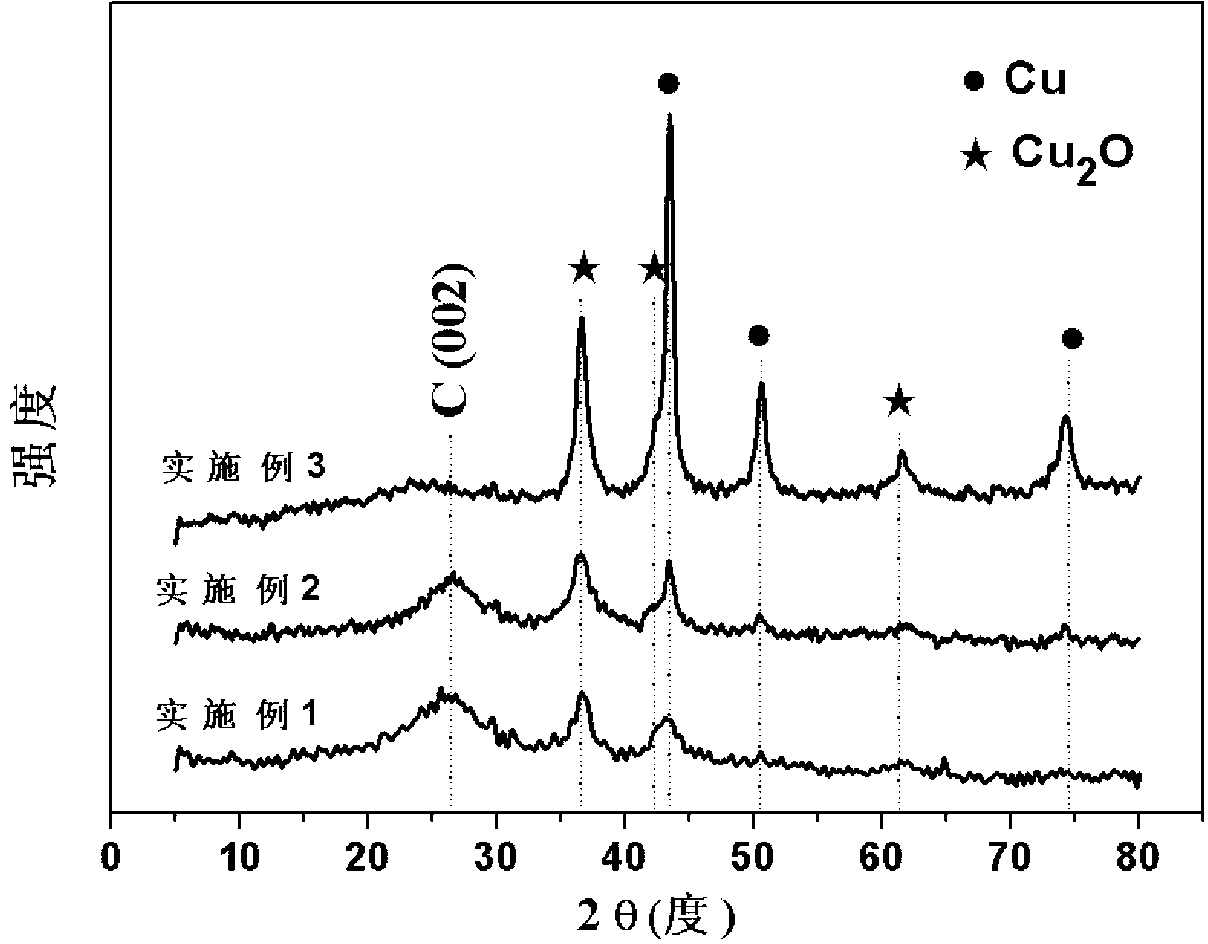

[0027] The XRD spectrum of the product of Example 1 is shown in figure 1 . The powder product in Example 1 and the solid paraffin were uniformly mixed according to the mass ratio of 1:1, and pressed in a special mold into a coaxial sample with an outer diameter of 7.00mm, an inner diameter of 3.04mm, and a thickness of about 3mm. The HP8720ES vector was used. The network analyzer ...

Embodiment 2

[0030] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, according to the mass ratio GO: CuCl 2 ·2H 2 O=1:1.33, weigh 133mg CuCl 2 ·2H 2 O, add to 200ml GO aqueous solution, stir for 30min, ultrasonic for 30min;

[0031] 2. According to the mass ratio GO: NaBH 4 =1∶10, weigh out 1g NaBH 4 Dissolve in 50ml water, drip into the mixed solution, react for 3h at room temperature;

[0032] 3. The obtained black precipitate is washed twice with deionized water by centrifugal washing method, and dried under vacuum at 60℃. The obtained black powder is RGO / Cu 2 O / Cu ternary composite material.

[0033] The XRD spectrum of the product of Example 2 is shown in figure 1 . The powder product in Example 1 and the solid paraffin were uniformly mixed according to the mass ratio of 1:1, and pressed in a special mold into a coaxial sample with an outer diameter of 7.00mm, an inner diameter of 3.04mm, and a thickness of about 3mm. The HP8720ES vector was used. The network analyzer test...

Embodiment 3

[0035] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, according to the mass ratio GO: CuCl 2 ·2H 2 O=1: 2.66, weigh 266mg CuCl 2 ·2H 2 O, add to 200ml GO aqueous solution, stir for 30min, ultrasonic for 30min;

[0036] 2. According to the mass ratio GO: NaBH 4 =1∶10, weigh out 1g NaBH 4 Dissolve in 50ml water, drip into the mixed solution, react for 3h at room temperature;

[0037] 3. The obtained black precipitate is washed twice with deionized water by centrifugal washing method, and dried under vacuum at 60℃. The obtained black powder is RGO / Cu 2 O / Cu ternary composite material.

[0038] The XRD spectrum of the product of Example 3 is shown in figure 1 . The powder product in Example 1 and the solid paraffin were uniformly mixed according to the mass ratio of 1:1, and pressed in a special mold into a coaxial sample with an outer diameter of 7.00mm, an inner diameter of 3.04mm, and a thickness of about 3mm. The HP8720ES vector was used. The network analyzer tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com