Green and environment-friendly sealing method for surface anode oxidization of aluminum alloy

A technology of aluminum alloy surface and anodic oxide film, applied in surface reaction electrolytic coating, electrolytic coating, coating and other directions, can solve the problem of poisonous sealing liquid, and achieve the effect of stable composition, uniform color and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The green environmental protection sealing treatment of 2A12 aluminum alloy anodic oxidation film includes the following steps:

[0016] Step 1: Configure blocking solution: cerium nitrate 5g / L, prepared with deionized water, heated to 30°C and stirred to accelerate dissolution;

[0017] The second step: hang the aluminum alloy sample containing the anodized film;

[0018] Step 3: Hang it into the blocking solution at 90°C, soak it for 25 minutes at a magnetic stirring rate of about 300 revolutions per minute, and then take the sample out of the blocking solution;

[0019] Step 4: Rinse the sample treated in the third step with clean water, and then rinse with deionized water for 10 seconds; the sample after deionized rinsing is dried with a hair dryer for 5 minutes.

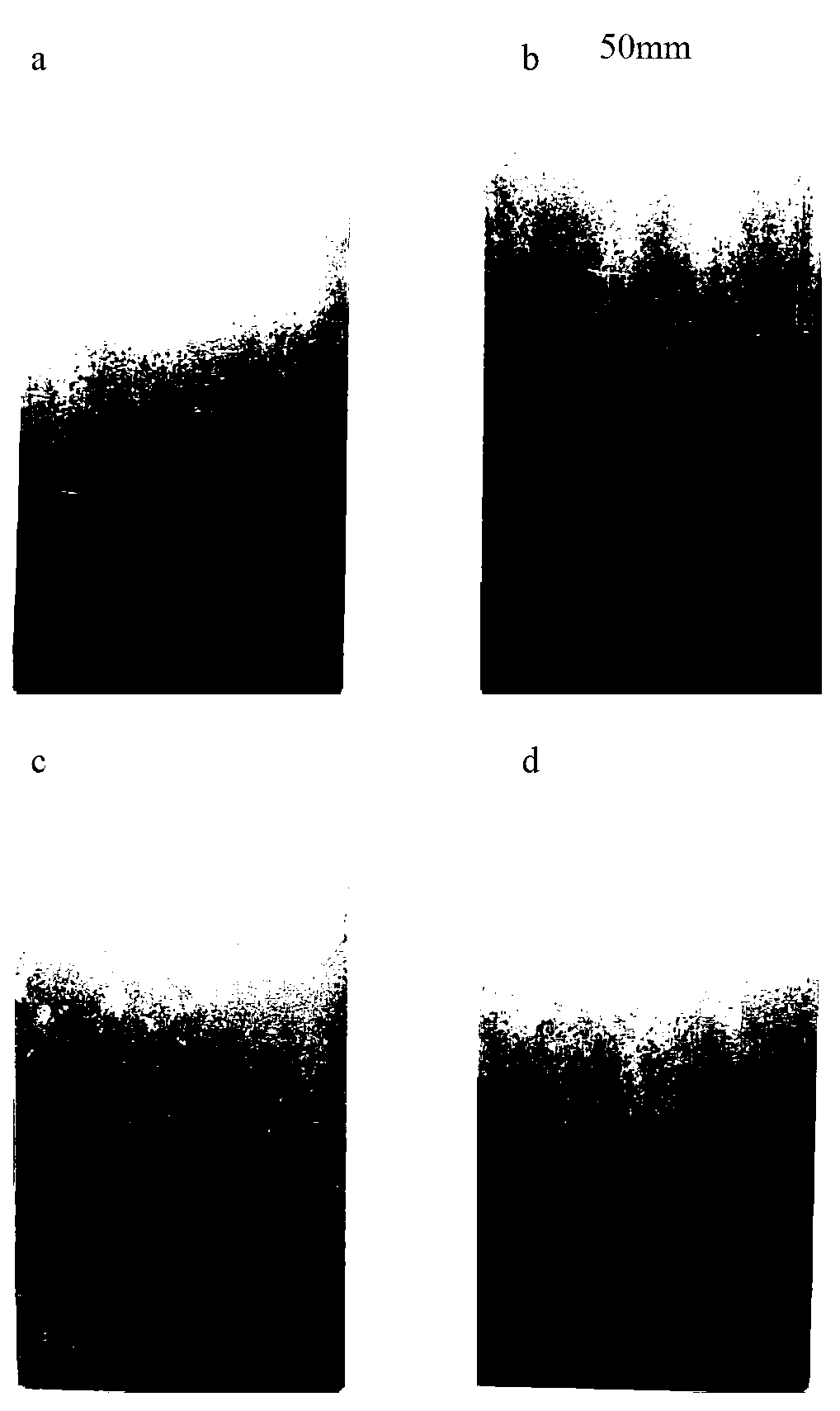

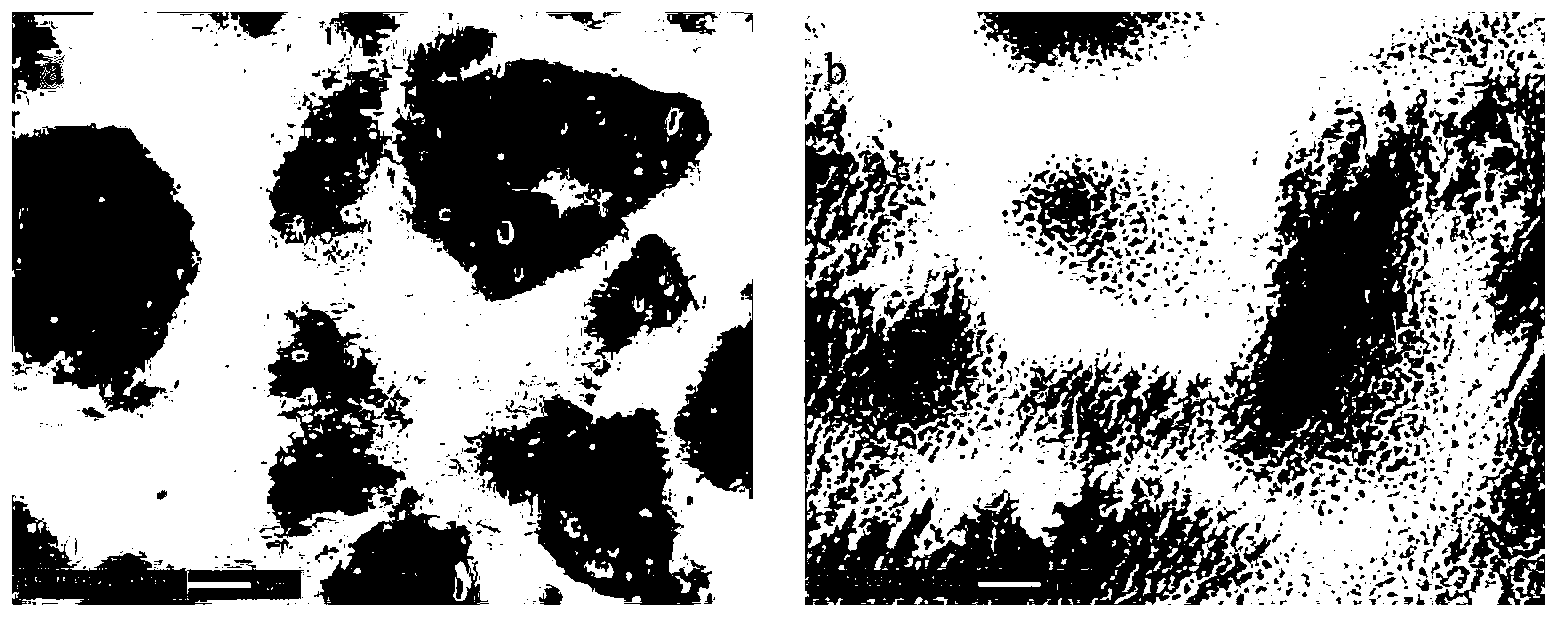

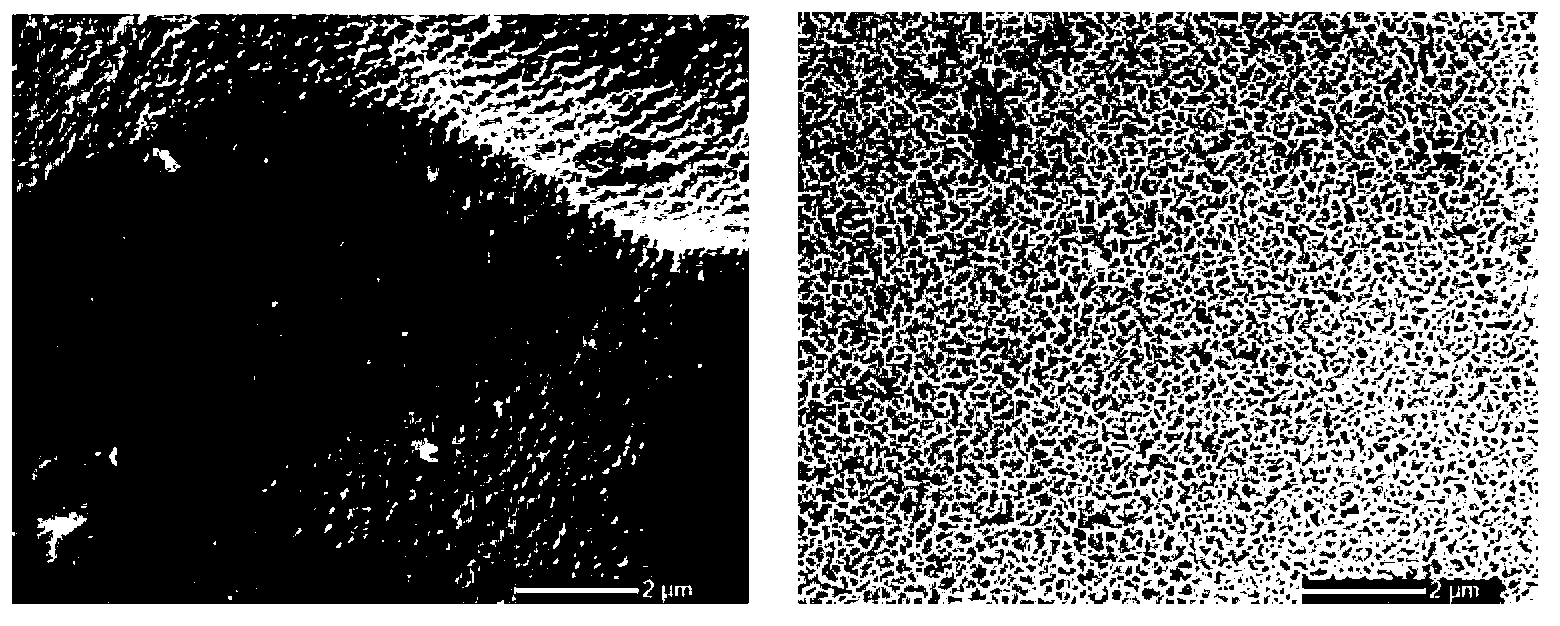

[0020] Take pictures of the samples before and after sealing. figure 1 In (a), (b) shown. Carry out scanning electron microscope SEM test before and after the sample is sealed, such as figure 2 In (a...

Embodiment 2

[0023] The green environmental protection sealing treatment of 2A12 aluminum alloy anodic oxidation film includes the following steps:

[0024] Step 1: Configure blocking solution: cerium nitrate 3-10g / L, prepared with deionized water, heat to 30-40°C and stir to accelerate dissolution;

[0025] The second step: hang the aluminum alloy sample containing the anodized film;

[0026] Step 3: Hang it into the blocking solution at 80°C, soak for 30 minutes at a magnetic stirring rate of about 300 rpm, and then take the sample out of the blocking solution;

[0027] Step 4: Rinse the sample treated in the third step with clean water, and then rinse it with deionized water for 10 seconds; dry the sample after deionized rinsing with a hair dryer for 3 minutes.

[0028] After sealing, do Tafel polarization curve test on the sample, the result is as follows image 3 Curve a

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com