Shield-type fire-retardant solar photovoltaic cable

A solar photovoltaic, fire-proof and flame-retardant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of being susceptible to electromagnetic interference, polluting the environment, releasing toxic and harmful gases, etc., and achieve good anti-electromagnetic interference, ensuring safety, and fire resistance Effect of burning effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

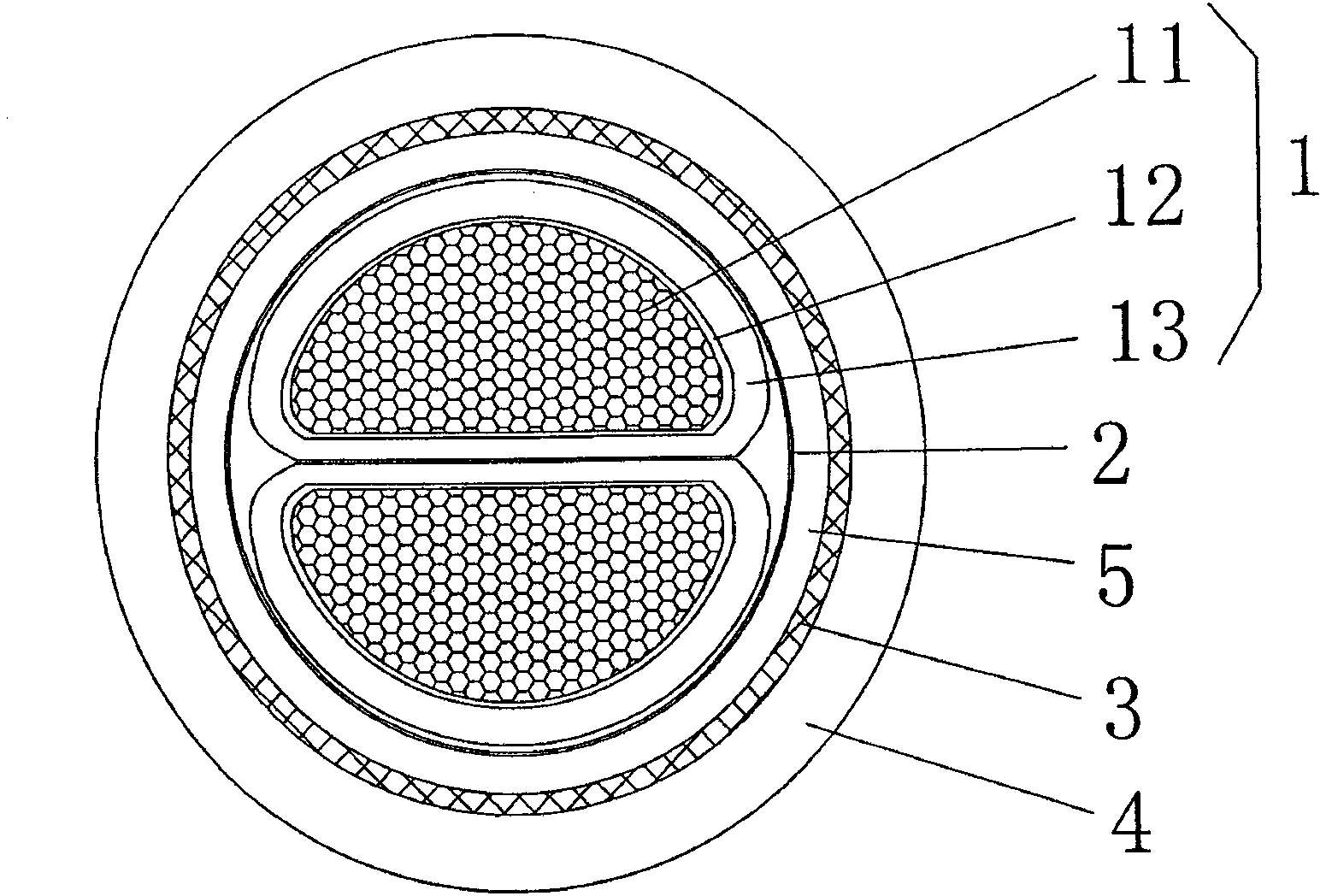

[0027] See figure 1 , Two cable cores are given. The cross-sectional shapes of the two cable cores 1 are both semicircular and equal in size. The following description is for one of the cable cores 1, which includes the core Conductor 11, core conductor flame-retardant fire-retardant tape 12 and core-conductor insulating sheath layer 13, core-conductor flame-retardant fire-retardant tape 12 uses mica tape with a thickness of 0.1 mm and a width of 40 mm, with a 30% stacking rate Outside the core conductor 11, the core conductor insulating sheath 13 is extruded outside the core conductor flame-retardant fire-retardant tape 12 by the usual technical means of wire and cable manufacturers. In this embodiment, the core conductor insulating sheath layer The material of 13 is radiation cross-linked low-smoke halogen-free polyethylene hydrocarbon, and the thickness is 1 mm. The aforementioned core conductor 11 is formed by twisting a set of bare copper wires, and has a cross-sectional a...

Embodiment 2

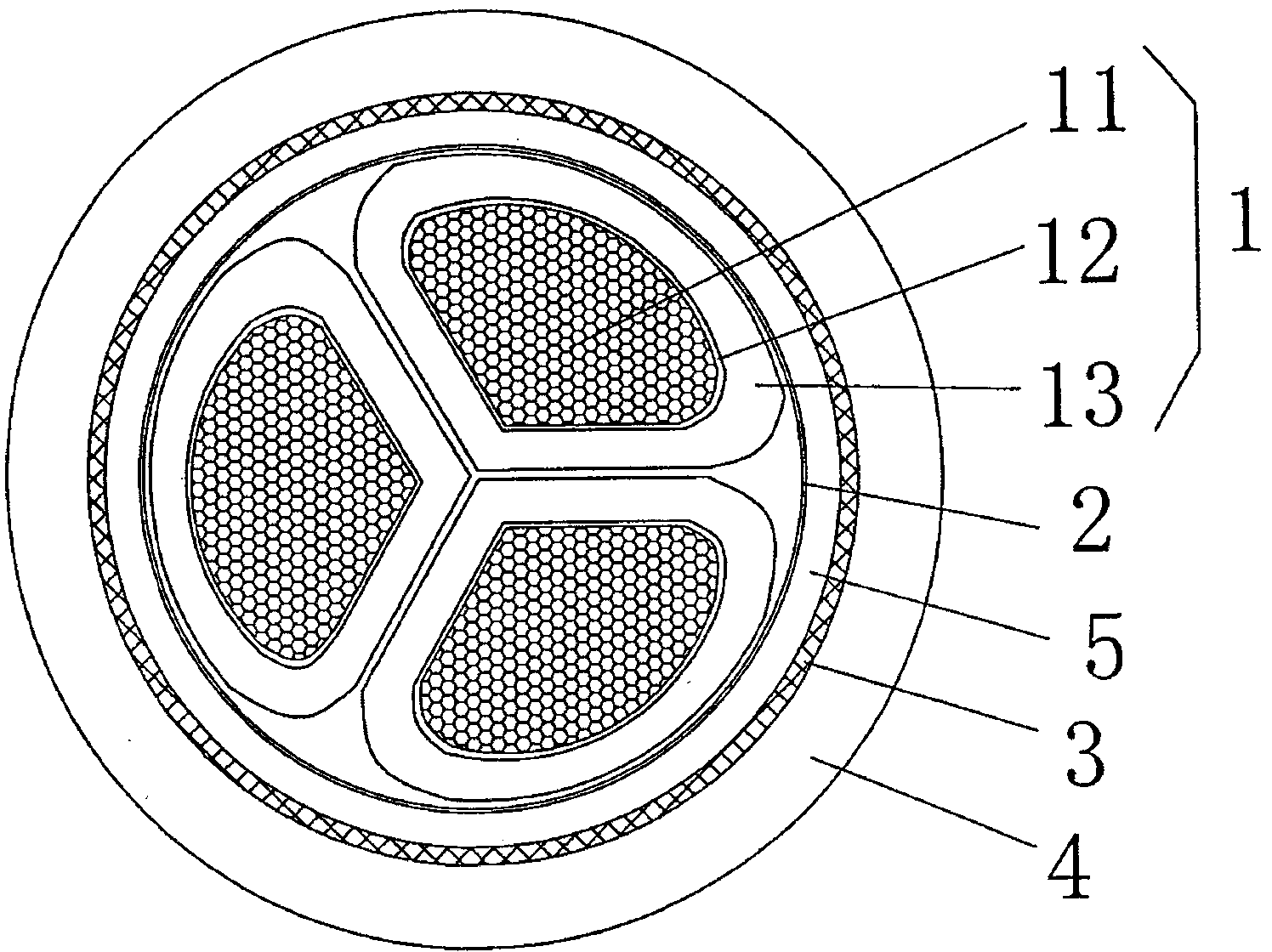

[0031] See figure 2 , Only the number of cable cores 1 is changed to three, and the cross-sectional shape of each cable core 1 is fan-shaped, and the cross-sectional area of the three core conductors 11 constituting the cable core 1 is changed to 3mm each 2 , And the stranded tinned thin copper wire constitutes the core conductor 11, the stacking rate of the core conductor flame retardant and fireproof tape 12 is changed to 50%, and the glass fiber tape with a thickness of 0.3 mm and a width of 8 mm is adopted As the core conductor flame-retardant fire-retardant tape 12; change the thickness of the conductor insulation sheath 13 to 0.7 mm; change the fire-retardant and flame-retardant coating layer 2 to glass fiber tape with a thickness of 0.15 mm and a width of 80 mm, and The stacking rate is changed to 30%; the thickness of the inner lining layer 5 is changed to 2mm; the thickness and width of the metal shielding layer 3 are changed to 0.3mm and 25mm respectively, and the st...

Embodiment 3

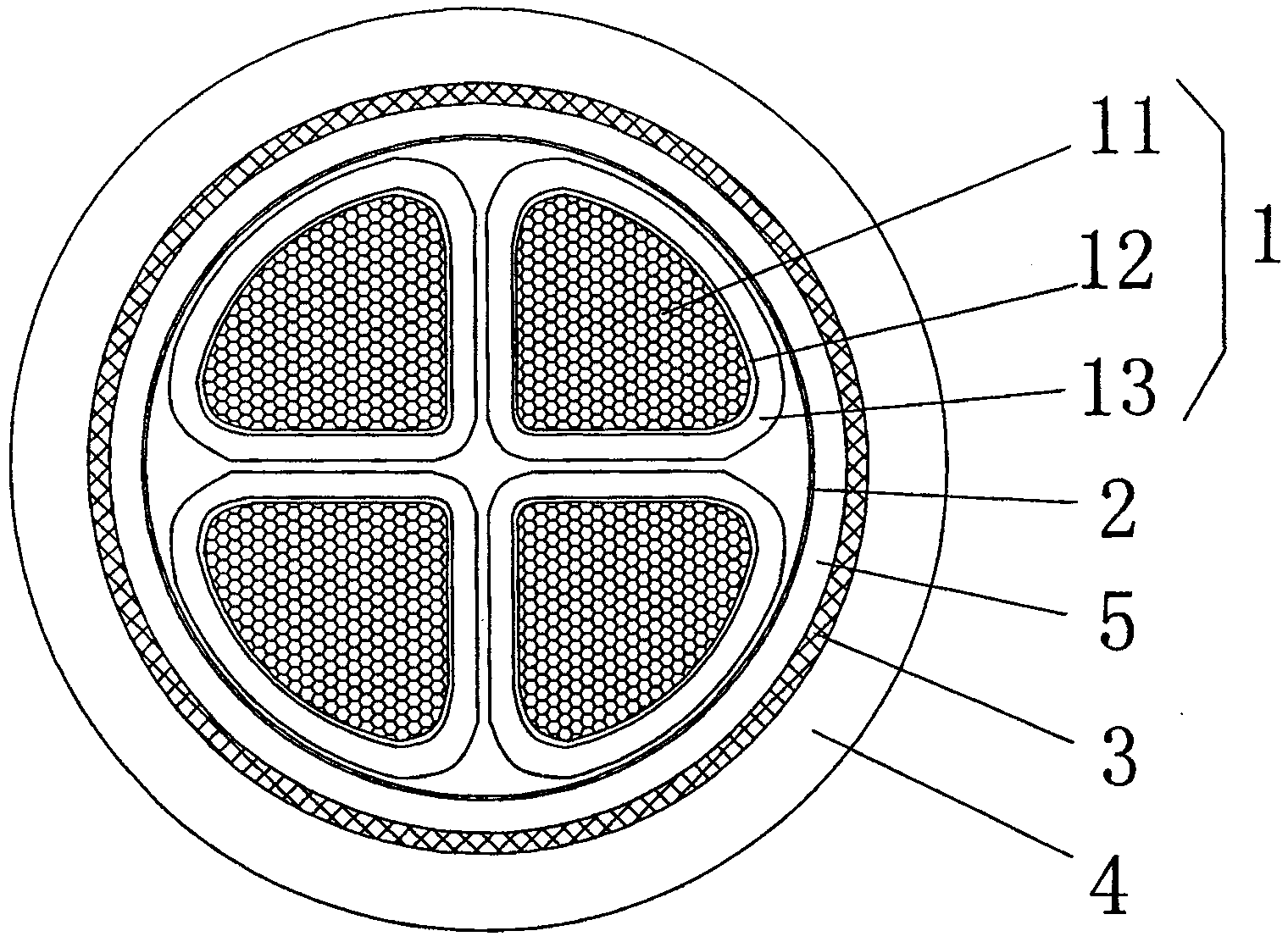

[0033] See image 3 , Only the number of cable cores 1 is changed to four, and the cross-sectional shape of each cable core 1 is fan-shaped, and the cross-sectional area of the four core conductors 11 constituting the cable core 1 is changed to 40mm. 2 , And the stranded copper clad aluminum aluminum wire constitutes the core conductor 11, the stacking rate of the core conductor flame-retardant fire-retardant tape 12 is changed to 40%, and the mica tape with a thickness of 0.2 mm and a width of 8 mm is used as Wire core conductor flame-retardant fire-retardant tape 12; change the thickness of the conductor insulation sheath 13 to 0.8 mm; change the thickness of the fire-retardant and flame-retardant coating layer 2 (using mica tape) to 0.1 mm and the width to 80 mm, and Change the stacking rate to 40%; change the thickness of the inner lining layer 5 to 0.6mm; change the thickness and width of the metal shielding layer 3 (double layer) to 0.15mm and 50mm, and change the stackin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com