Method for synthesizing silicon nitride nano ring by CVD (chemical vapor deposition) method

A technology of silicon nitride and nano rings, which is applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of difficult purification and cumbersome preparation process, and achieve easy-to-obtain, simple preparation process, simple and efficient preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

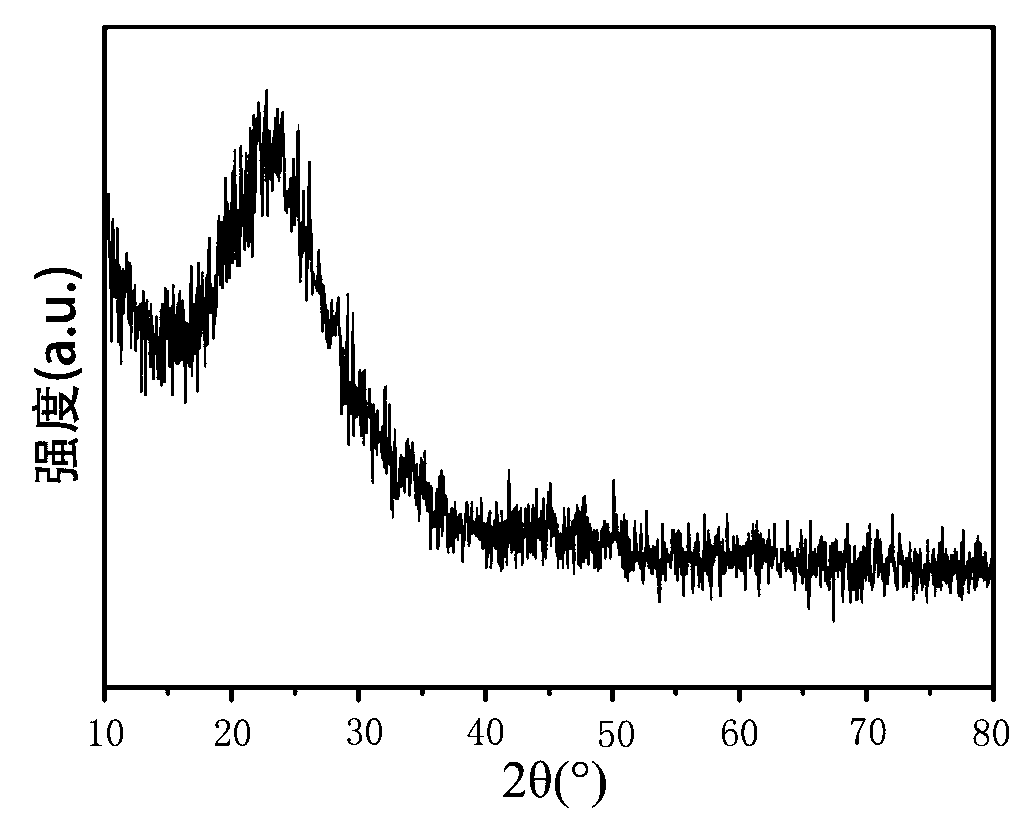

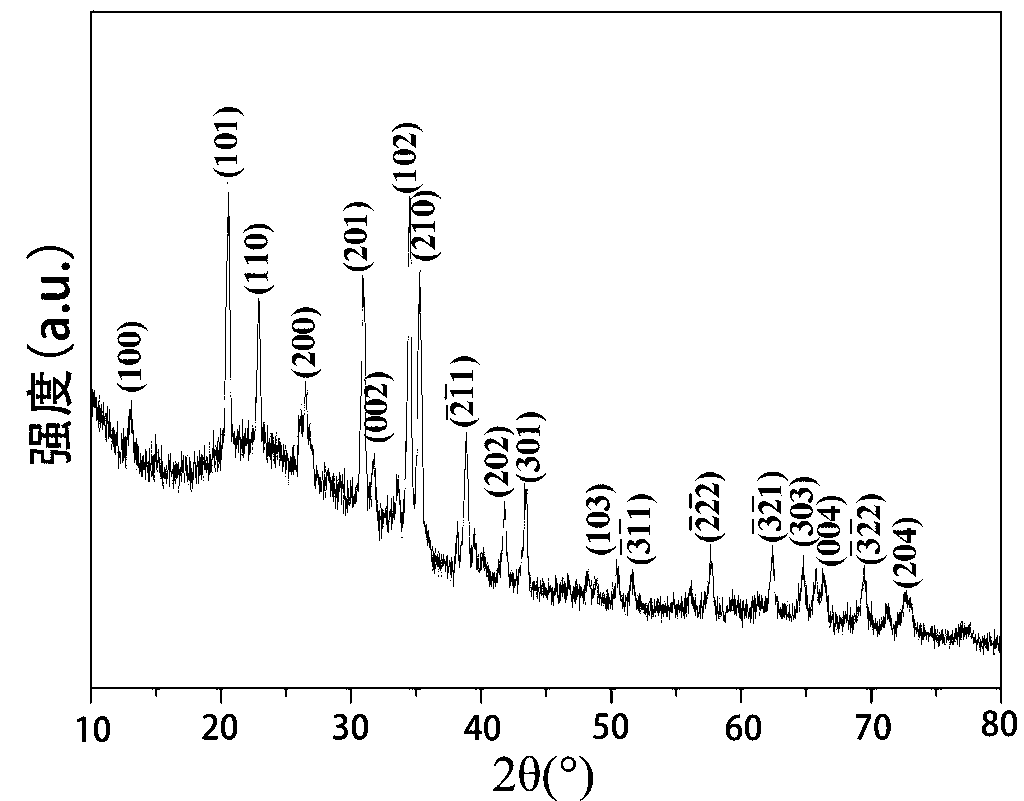

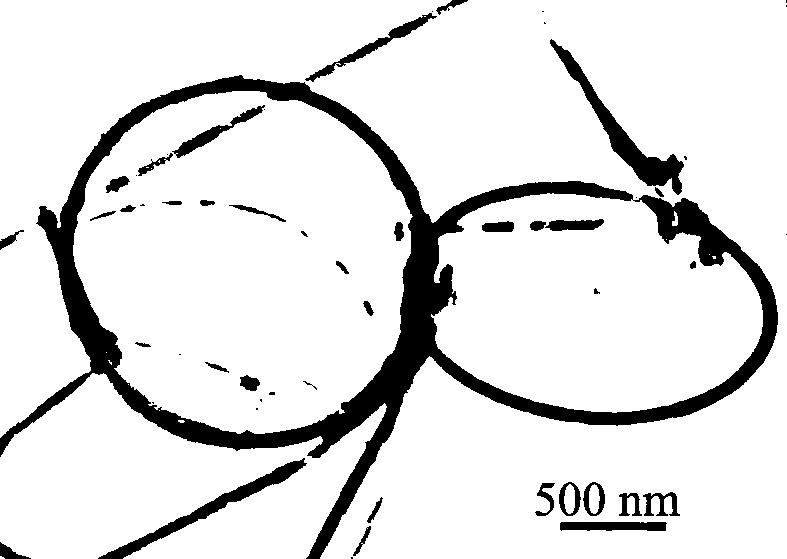

Embodiment 1

[0047] Weigh 0.28g of commercially available 200-mesh silicon powder and 0.6g of commercially available amorphous silica powder at a molar ratio of 1:1, mix the two evenly and place them in a corundum boat; place the corundum with the mixed powder Put the boat into the central area of the horizontal tubular resistance furnace, seal the two ends of the horizontal tubular resistance furnace and vacuumize it to remove the oxygen in the reaction chamber as much as possible; then feed nitrogen and Ammonia gas is used as the nitriding reaction gas, the gas flow volume ratio of high-purity nitrogen gas and ammonia gas is 3:1, and the atmosphere flow rate is 120 sccm; after the gas flow is stable, start heating the horizontal tubular resistance furnace so that it can be heated at a rate of 5°C / min. The heating rate is raised to 1300°C; heat preservation at 1300°C for 2 hours, then close the heating furnace, stop heating the horizontal tubular resistance furnace, and continue to pass ...

Embodiment 2

[0049] Weigh 0.28g of silicon powder obtained by wet ball milling process and 0.6g of commercially available amorphous silicon dioxide powder at a molar ratio of 1:1, mix the two evenly and place them in a corundum boat; put the mixed powder Put the corundum boat into the central area of the horizontal tube resistance furnace, seal the two ends of the horizontal tube resistance furnace and vacuumize it to remove the oxygen in the reaction chamber as much as possible; then pass into the horizontal tube resistance furnace Nitrogen and ammonia are used as nitriding reaction gases. The gas flow volume ratio of high-purity nitrogen and ammonia is 1:5, and the atmosphere flow is 80 sccm. After the air flow is stable, start heating the horizontal tube resistance furnace to make it 5 ℃ / The heating rate of min is raised to 1200°C; keep warm at 1200°C for 6 hours, then close the heating furnace, stop heating the horizontal tubular resistance furnace, and continue to feed the nitridin...

Embodiment 3

[0051] Weigh 0.28 g of silicon powder obtained by wet ball milling (ball milling commercially available 200-mesh silicon powder) and 0.6 g of commercially available amorphous silica powder at a molar ratio of 1:1, mix the two evenly and place in In the corundum boat; put the corundum boat containing the mixed powder into the central area of the horizontal tubular resistance furnace, seal the two ends of the horizontal tubular resistance furnace and vacuumize it to remove the oxygen in the reaction chamber as much as possible; Then feed nitrogen and ammonia into the horizontal tubular resistance furnace as the nitriding reaction gas. The gas flow volume ratio of high-purity nitrogen and ammonia is 3:1, and the atmosphere flow is 120 sccm; start heating the horizontal tube after the gas flow is stable. Type electric resistance furnace, make it heat up to 1300°C at a heating rate of 8°C / min; keep warm at 1300°C for 2 hours, then close the heating furnace, stop heating the horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com