Clostridium acetobutylicum and applications thereof

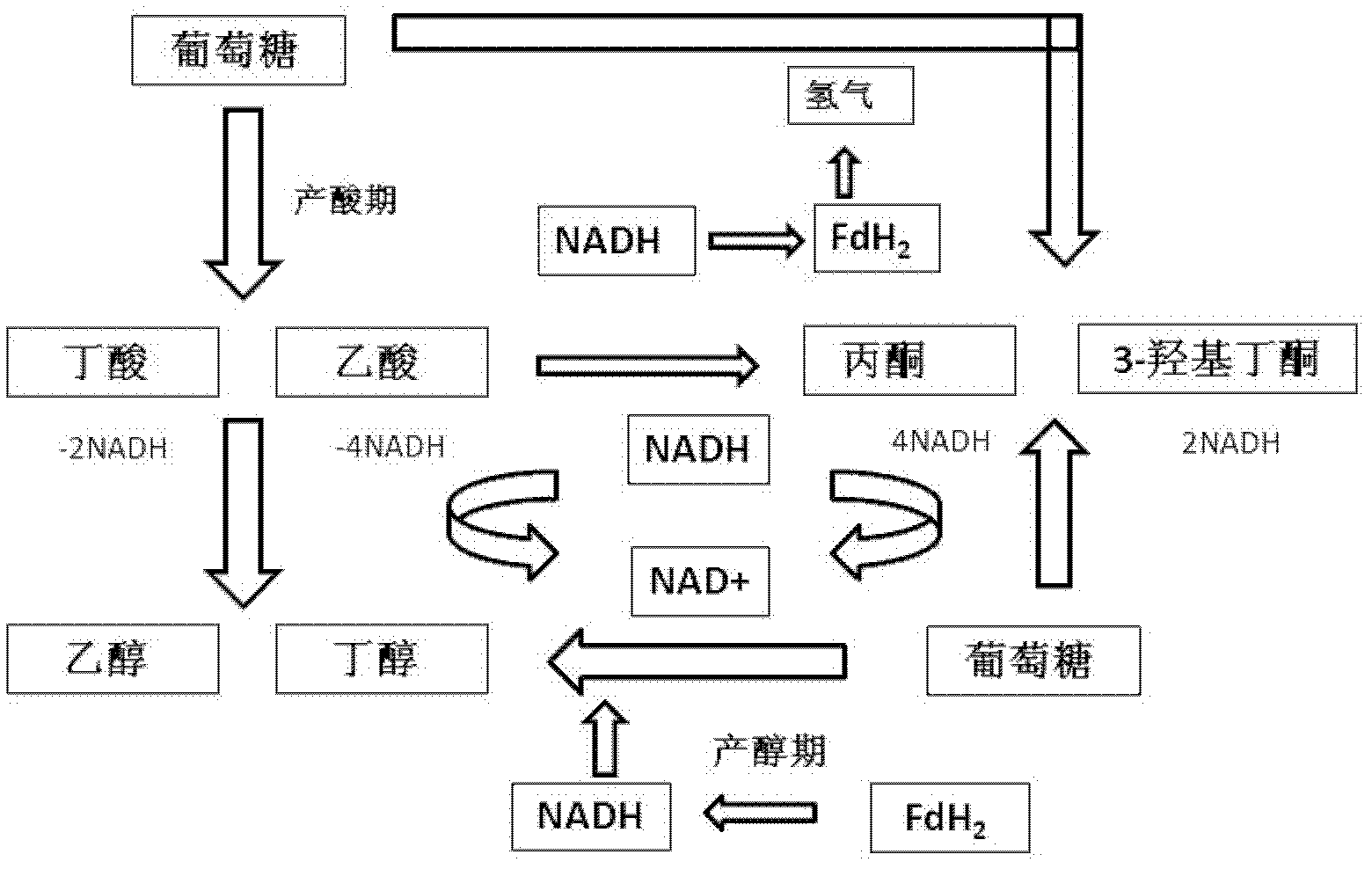

A technology of Clostridium acetobutylicum and butanol, which is applied in the field of microorganisms, can solve the problems such as the effective utilization of NADH and the waste of NADH in the separate regulation of difficult metabolic flow, and achieve flexible adjustment of metabolic flow, increase carbon yield, and improve product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Mutagenesis of Clostridium acetobutylicum

[0052] Clostridium acetobutylicum (Clostridium acetobutylicum) was used as the original bacterial strain, activated and cultured on the plate for 24 hours, then transferred once, and a ring of bacteria sludge was picked and added to 60mM lithium chloride sterile aqueous solution with 100 glass beads. Shake 100ml in a shaker flask at 200rpm for 10min to evenly disperse the bacteria, then take 1mL of the bacterial suspension on a sterile plate and put it in a 254nm ultraviolet mutagenesis box for 90s, then dilute it 100 times and spread it on bromine containing 20mg / L On cresyl violet plates, cultured anaerobically at 37°C for 3 days. A total of 120 colonies with large colonies, early discoloration time, and larger and brighter discoloration circles were selected as primary strains, and fermented after expanded cultivation to verify yield and stability. Finally, a strain of Clostridium acetobutylicum B3 (Clostridium...

Embodiment 2

[0059]Fermentation medium: glucose 60g / L, ammonium acetate 3g / L, corn steep liquor 2ml / L, sterilized at 121°C for 15min.

[0060] After the seed solution was mixed, it was inserted into a 5L fermenter with a 10% inoculum amount, and the liquid amount was 60%, and it was cultured statically at 37° C. for 80 h.

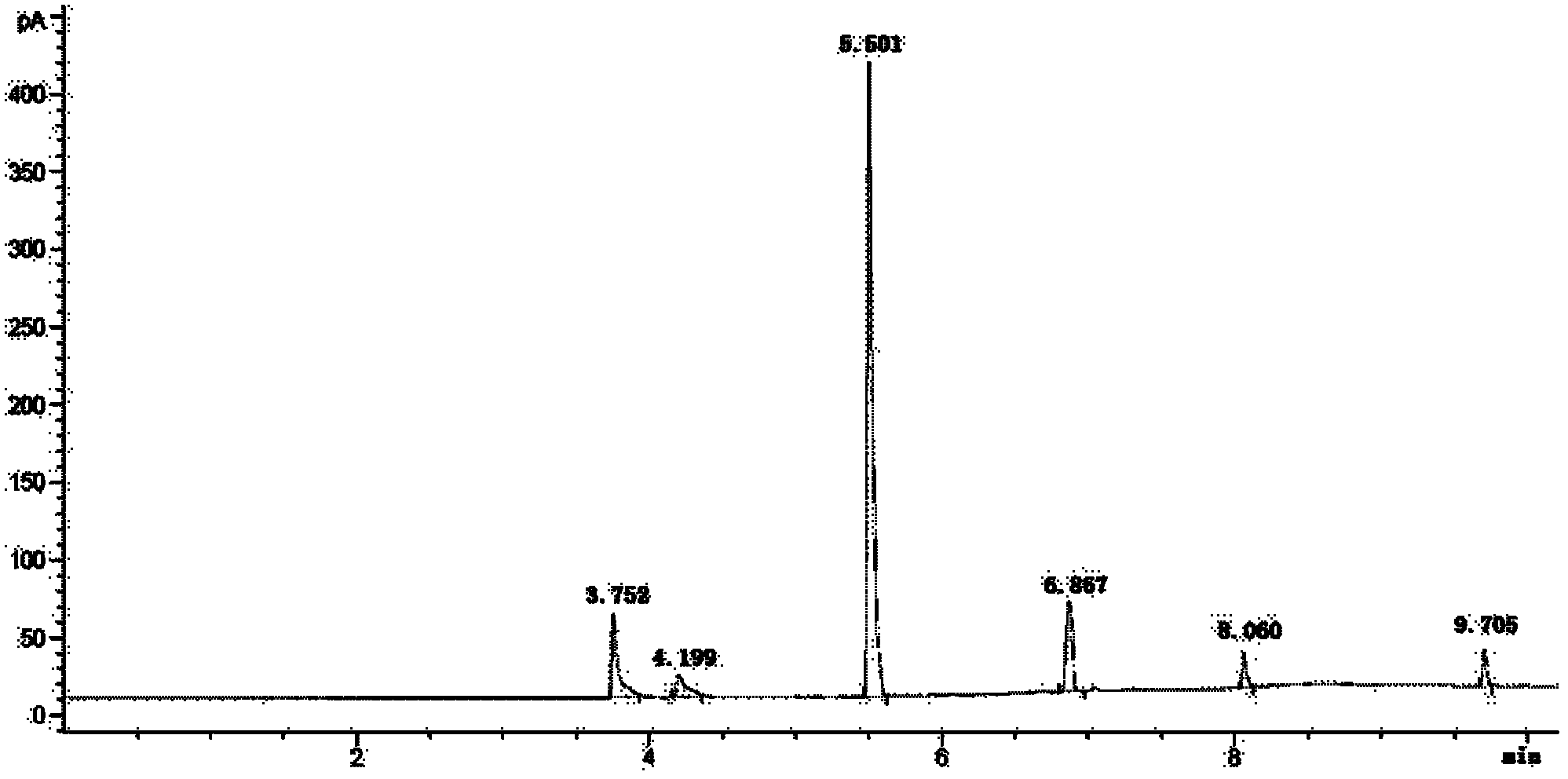

[0061] In the fermented liquid finally obtained, acetone was 3.9 g / L, ethanol was 0.8 g / L, butanol was 11.9 g / L, and 3-hydroxybutanone was 2.4 g / L.

Embodiment 3

[0063] Fermentation medium: 6% corn flour, gelatinized in boiling water for 60 minutes, sterilized at 121°C for 30 minutes.

[0064] After the seed solution was mixed, it was inserted into a 5L fermenter with a 5% inoculum size, and the liquid volume was 3L, and it was cultured statically at 37° C. for 50 h.

[0065] In the fermentation broth finally obtained, acetone was 4.2g / L, ethanol was 1.1g / L, butanol was 11.8g / L, and 3-hydroxybutanone was 2.1g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com