Flame-retardant pure silk and preparation method thereof

A real silk and silk technology, applied in fiber processing, textiles and papermaking, animal fibers, etc., can solve the problems of large amount of smoke, decreased amount of smoke, environmental pollution, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: real silk is degummed whitening real silk electric spinning

[0030] Prepare 1% sodium phytate solution, 1% low molecular weight chitosan solution, add 1% glacial acetic acid to aid dissolution, and adjust the pH of the low molecular weight chitosan solution to 4.5 with glacial acetic acid;

[0031] The degummed silk is first immersed in low molecular weight chitosan solution for 30 minutes, taken out, washed with deionized water, dried at 70°C, then immersed in sodium phytate solution for 30 minutes, taken out, washed with deionized water, dried at 70°C, Beginning with three immersions, each immersion time is 2 minutes, after each immersion, wash with deionized water and dry at 70°C;

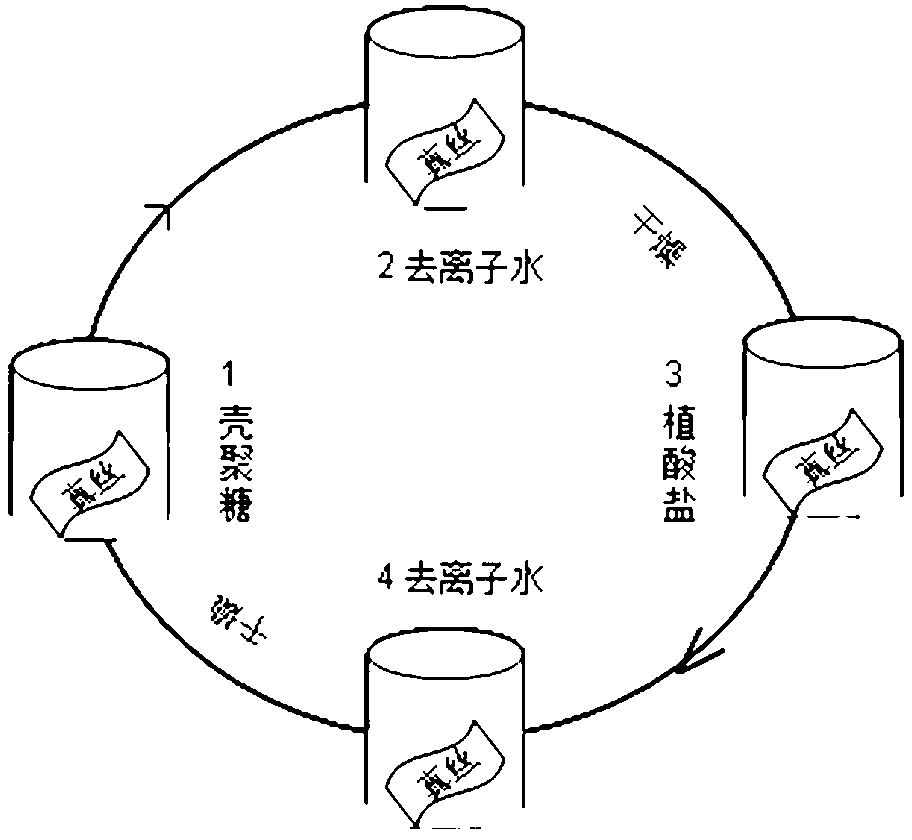

[0032] attached figure 1 It is a schematic diagram of the preparation process of flame-retardant silk in the present invention. 1 means that the degummed silk is first immersed in a low molecular weight chitosan solution, and then begins to go through 2—washing with deio...

Embodiment 2

[0041] Embodiment two: real silk fabrics are white plain satin, sky blue electric spinning, navy blue double palace silk

[0042] Prepare 2% sodium phytate solution, 1% low molecular weight chitosan solution, add 1% glacial acetic acid to aid dissolution, and adjust the pH value of the chitosan solution to 5.5 with glacial acetic acid. Silk is first immersed in chitosan solution for 5 minutes, taken out, washed with deionized water, dried at 70°C, then immersed in sodium phytate solution for 5 minutes, taken out, washed with deionized water, dried at 70°C, starting from three immersions , and each alternate immersion time is 5 min, and after each immersion, it is washed with deionized water and dried at 70 °C.

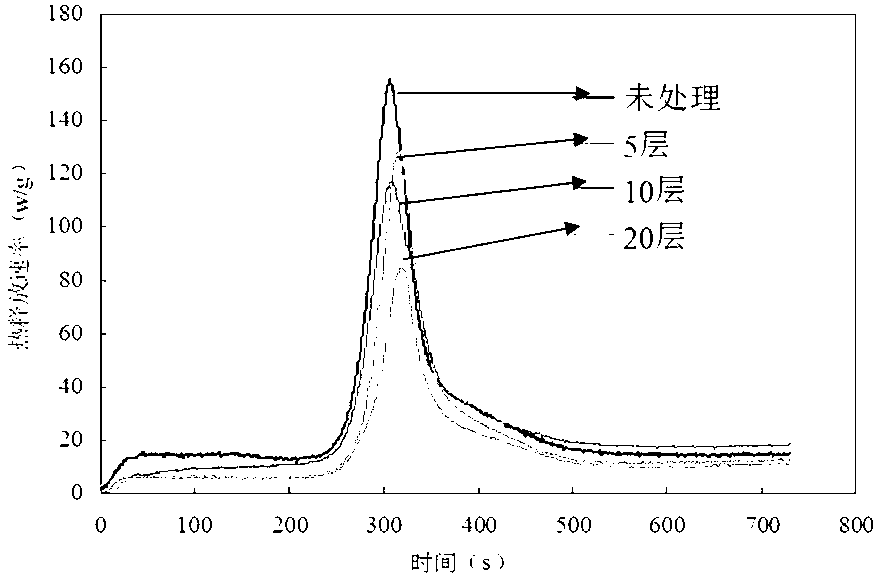

[0043] Table 2 lists the limiting oxygen indices of the three silk fabrics after assembling 5 layers, 10 layers, and 20 layers respectively. It can be seen from Table 2 that after flame retardant treatment, the flame retardant properties of silk fabrics have been great...

Embodiment 3

[0046] Embodiment three: real silk is degummed whitening real silk electric spinning

[0047] Prepare 0.5% sodium phytate solution, 0.5% low molecular weight chitosan solution, add 0.5% glacial acetic acid to aid dissolution, and adjust the pH of the low molecular weight chitosan solution to 5;

[0048]Silk is first immersed in low molecular weight chitosan solution for 20 minutes, taken out, washed with deionized water, dried naturally, then immersed in sodium phytate solution for 20 minutes, taken out, washed with deionized water, dried naturally, starting from three dippings , each soaking time is 1 min, wash with deionized water after each soaking, and dry naturally; according to the attached figure 1 The step cycle is assembled 5 times, that is, 5 layers. In this example, after 5 layers are assembled, the limiting oxygen index of silk electric spinning increases from untreated 23.1 to 27.8 after treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com