Chromo board coating and application thereof

A copperplate card and coating technology, applied in paper coatings, coatings, pigmented coatings, etc., to achieve the effects of increased output, high strength, and delicate touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

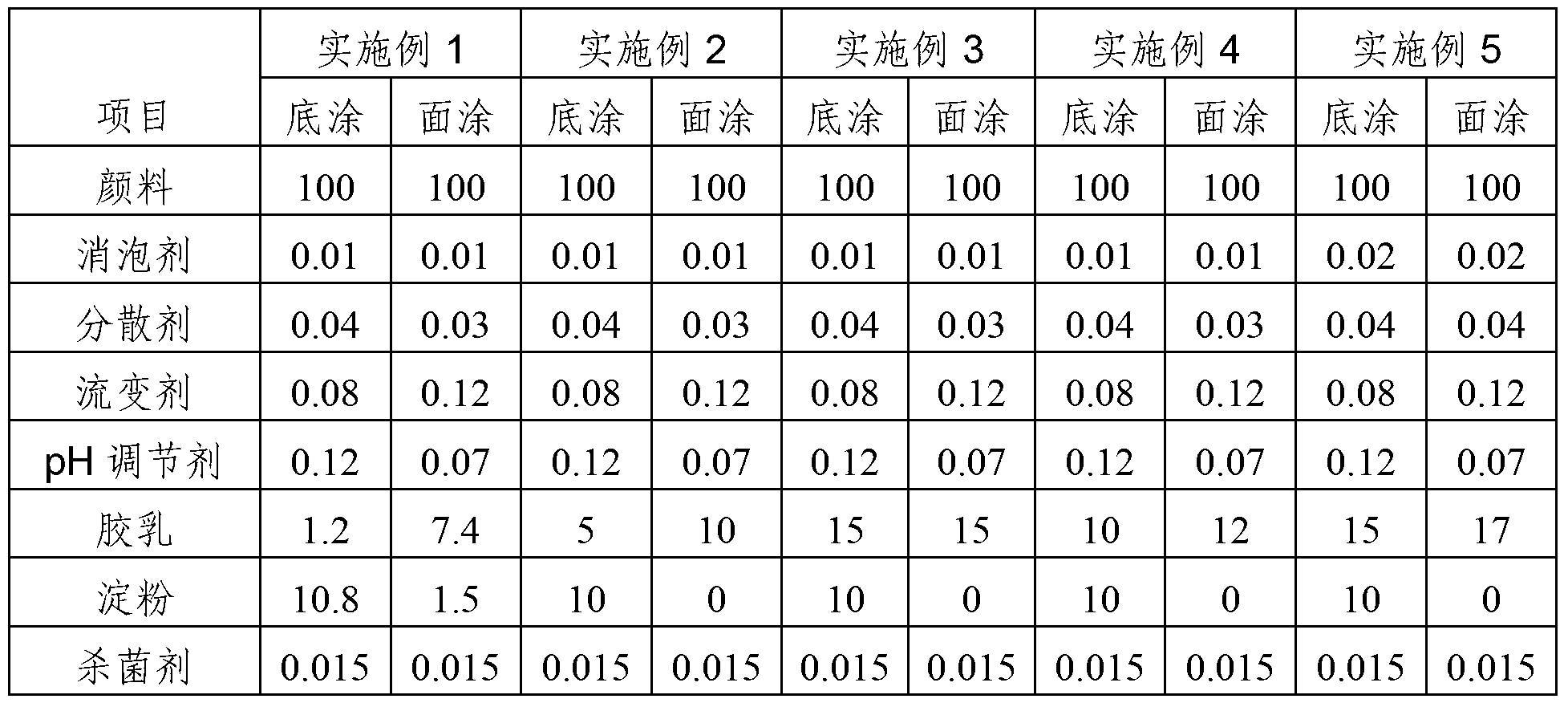

[0026] Primer: 100 parts of china clay, 10.8 parts of corn starch, 1.2 parts of styrene-butadiene latex, 0.01 part of polyethylene glycol, 0.08 part of sodium carboxymethyl cellulose, 0.04 part of sodium hexametaphosphate; 0.01 part of isothiazolinone parts, 0.12 parts of sodium hydroxide.

[0027] Topcoat: 100 parts of china clay, 1.5 parts of corn starch, 7.4 parts of styrene-butadiene latex, 0.01 part of polyethylene glycol, 0.12 parts of sodium carboxymethyl cellulose, 0.03 parts of sodium hexametaphosphate; 0.01 parts of isothiazolinone Parts, 0.07 parts of sodium hydroxide.

[0028] Add each material according to the order of the formula in Table 1, and after high-speed dispersion, a uniformly dispersed coating can be obtained. at 164g / m 2 The two sides of the copperplate unscaled raw paper are coated with bottom and top layers, and the coating amount of the bottom coating layer is 20g / m 2 , the coating amount of the top coat is 14g / m 2 , the total coating weight is ...

Embodiment 2

[0032] Primer: 100 parts of talcum powder, 10 parts of corn starch, 5 parts of styrene-butadiene latex, 0.01 part of polyethylene glycol, 0.08 part of sodium carboxymethyl cellulose, 0.04 part of sodium hexametaphosphate; isothiazolinone 0.01 part, 0.12 part of sodium hydroxide;

[0033] Topcoat: 100 parts of talcum powder, 10 parts of styrene-butadiene latex, 0.01 part of polyethylene glycol, 0.12 part of sodium carboxymethyl cellulose, 0.03 part of sodium hexametaphosphate; 0.01 part of isothiazolinone, hydroxide Sodium 0.07 parts.

[0034] Add materials according to the order of the formula in Table 1 to form high-speed dispersed uniform coatings respectively. at 164g / m 2 The two sides of the copperplate unscaled raw paper are coated with bottom and top layers, and the coating amount of the bottom coating layer is 20g / m 2 , the coating amount of the top coat is 14g / m 2 , the total coating weight is 68g / m 2 . The control of coating on both sides is basically the same, ...

Embodiment 3

[0038] Primer: 100 parts of clay, 10 parts of wheat starch, 10 parts of styrene-butadiene latex, 0.01 part of fatty acid antifoaming agent, 0.08 part of sodium carboxymethyl cellulose, 0.04 part of sodium pyrophosphate; 0.01 part of isothiazolinone , 0.12 parts of sodium hydroxide;

[0039] Topcoat: 100 parts of white clay, 12 parts of styrene-butadiene latex, 0.01 part of polyethylene glycol, 0.12 part of sodium carboxymethyl cellulose, 0.03 part of sodium pyrophosphate; 0.01 part of isothiazolinone, 0.07 part of sodium hydroxide share.

[0040] Add materials according to the order of the above primer and top paint formulations to form high-speed dispersed uniform paints. at 164g / m 2 The two sides of the copperplate unscaled raw paper are coated with bottom and top layers, and the coating amount of the bottom coating layer is 20g / m 2 , the coating amount of the top coat is 14g / m 2 , the total coating weight is 68g / m 2 . The control of coating on both sides is basically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com