Double-wafer integrated silicon-based super-thin micro-hemispherical resonator gyroscope and preparation method thereof

A hemispherical resonant gyroscope, an integrated technology, is used in instruments, microstructure technology, semiconductor devices, etc., and can solve the problems of limiting the production and application of micro-hemispherical resonant gyroscopes, low level of micromachining technology, etc. Low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

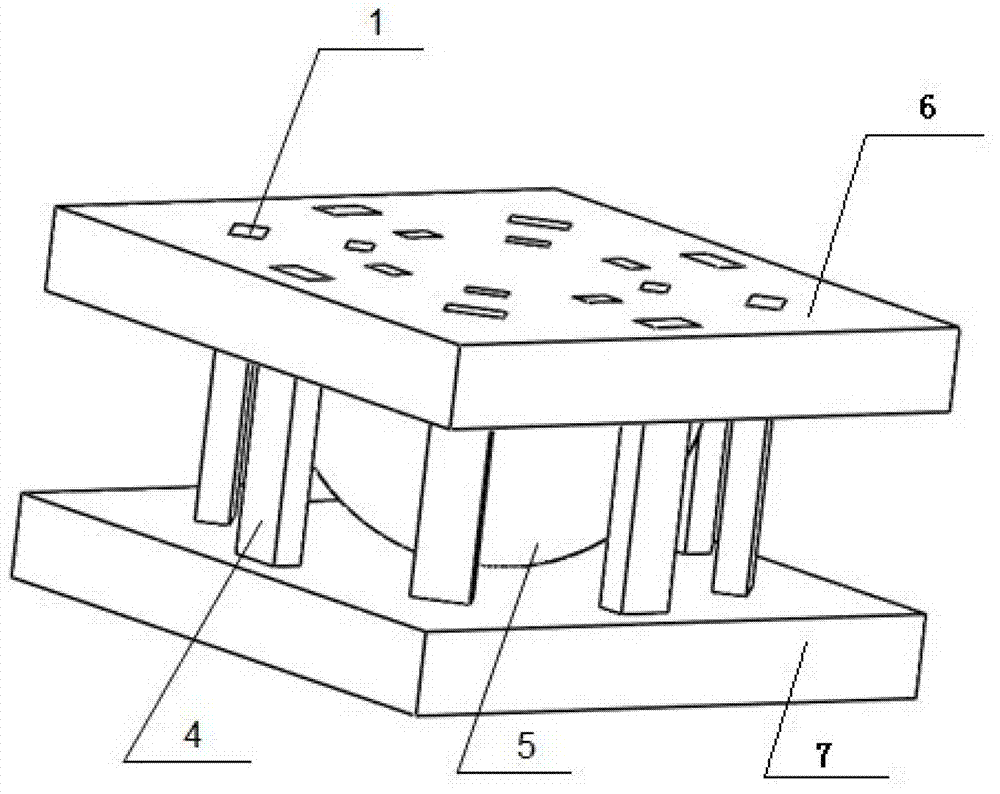

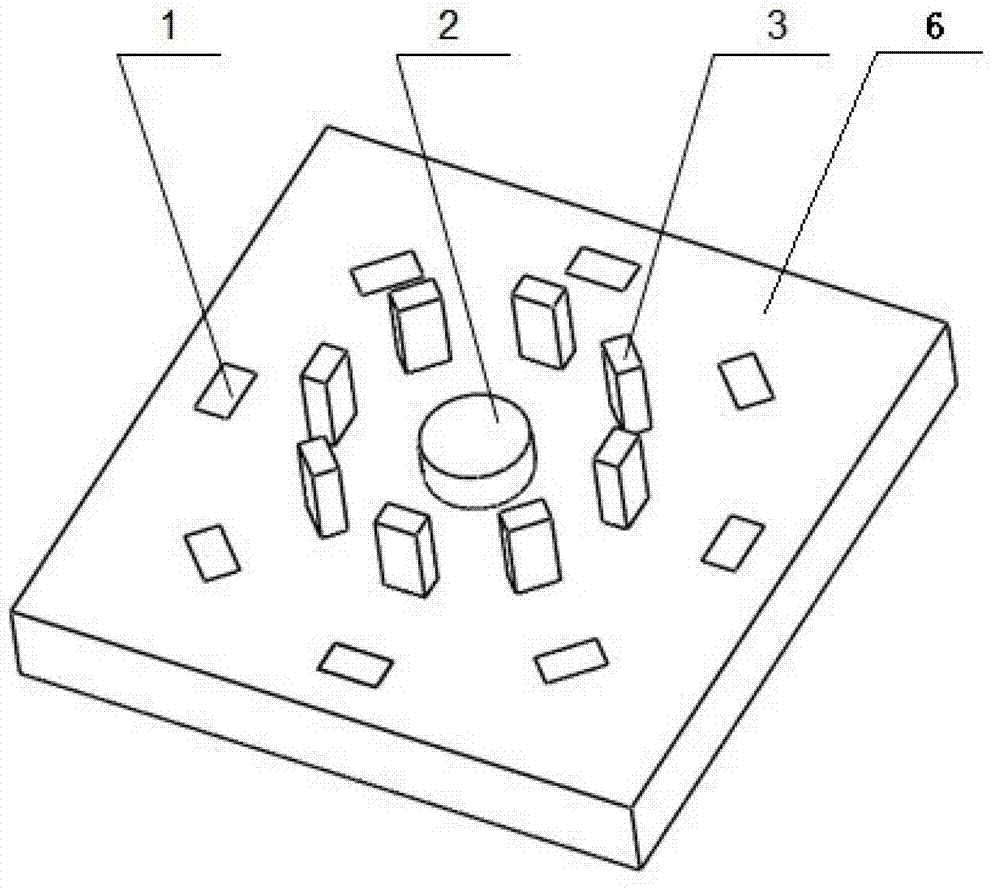

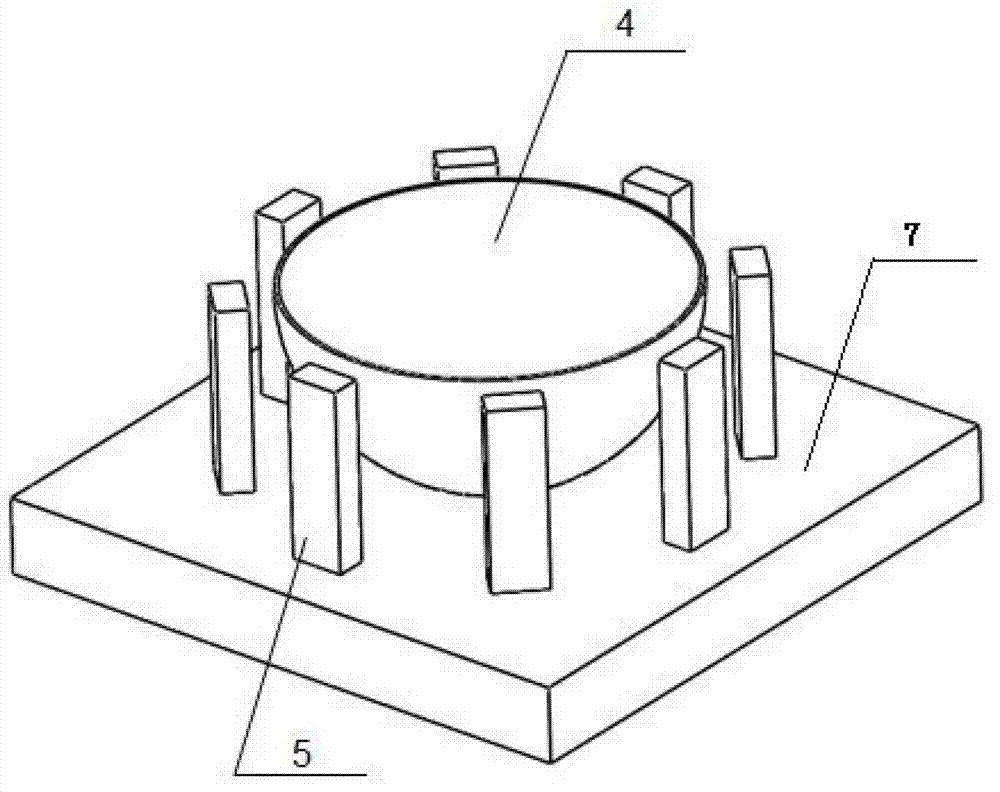

[0039] Such as Figure 1-3 A double-chip integrated silicon-based ultra-thin micro-hemispheric resonant gyroscope is shown, including a first silicon chip, a second silicon chip, a micro-hemispherical shell, a driving electrode and a detection electrode, and the micro-hemispherical shell is arranged on the first silicon chip and the second silicon chip, the bottom of the micro-hemispherical shell is fixedly connected with the second silicon chip, and the upper edge of the micro-hemispherical shell is in contact with the lower surface of the first silicon chip; the driving electrodes are arranged on the first silicon chip and the second silicon chip. One end of the driving electrode is fixedly connected to the second silicon chip, and the other end is movably connected to the first silicon chip; one end of the detection electrode is fixedly connected to the first silicon chip, and the other end is connected to the micro hemispherical shell. Inner wall articulation.

[0040] ...

Embodiment 2

[0054] Basically the same as embodiment 1, the difference is:

[0055] In step (6) of the processing method of the above-mentioned double-chip integrated silicon-based ultra-thin micro-hemispheric resonant gyroscope, the micro-hemispherical structure is prepared by deposition method, and the structural material deposited on the upper surface is removed by chemical mechanical polishing (CMP), so that the The single crystal silicon is exposed for subsequent release of the spherical shell.

Embodiment 3

[0057] Basically the same as embodiment 1, the difference is:

[0058] In the step (7) of the processing method of the above-mentioned double-chip integrated silicon-based ultra-thin micro-hemispherical resonant gyroscope: use TMAH wet etching to release the spherical shell structure, and then use hydrofluoric acid or BOE to remove the silicon dioxide on the electrode surface so that Expose the polysilicon electrodes.

[0059] Working principle: Each chip of the micro-hemispherical resonant gyroscope is assembled using the flip chip technology (Flip chip, that is, the flip-chip packaging method), and its alignment error can be precisely controlled below 1 micron, and because the driving electrode has been aligned with the micro-hemispheric The shell is integrated on the same silicon wafer, so only one inversion method is needed to assemble the two silicon wafers where the detection electrode and the micro-hemispherical shell are located, and finally perform vacuum packaging. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com