GaN-base LED epitaxial structure and growing method thereof

An epitaxial structure and growth method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large quantum barrier thickness, long barrier time, and increase material production costs, and achieve high luminous efficiency and low growth costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

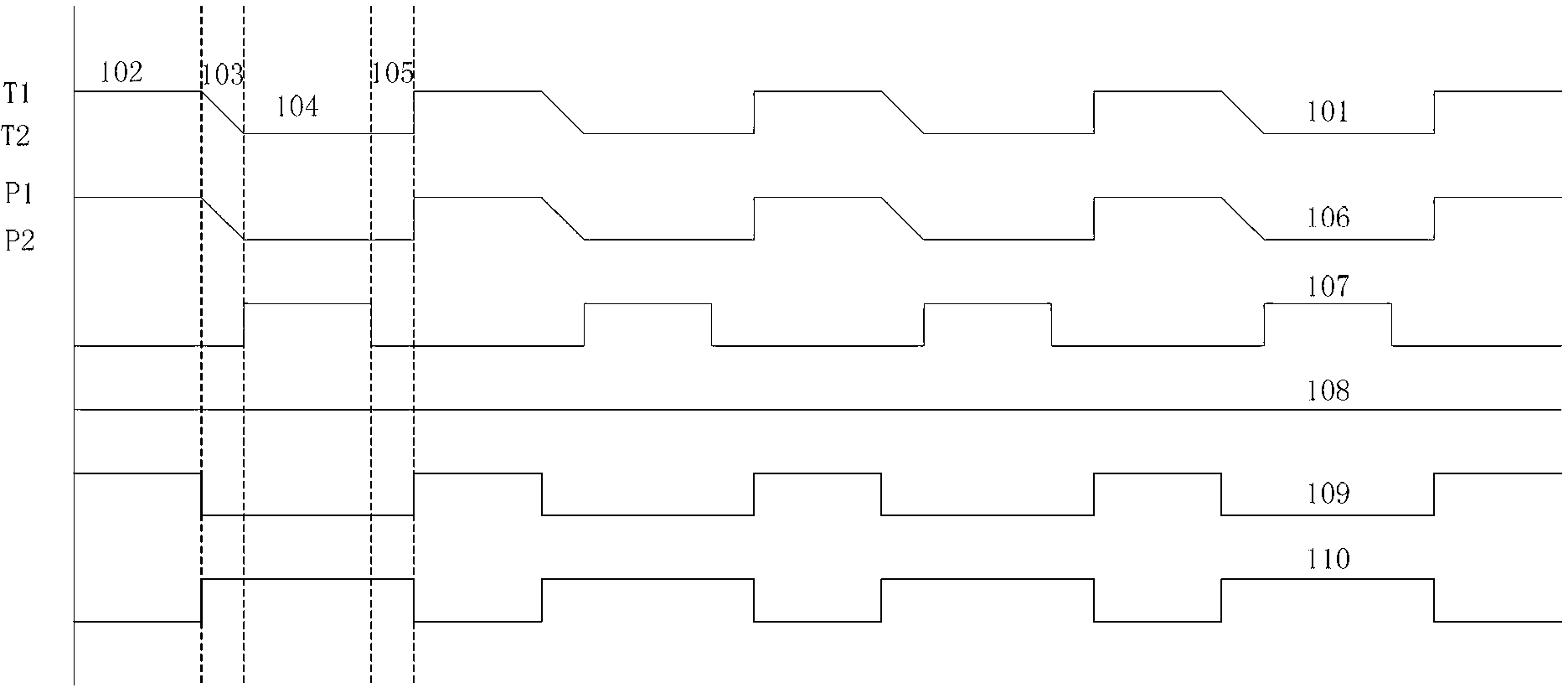

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0022] In the embodiment of the present invention, the method for growing the epitaxial structure of GaN-based LED may include the following steps:

[0023] Step 1, sequentially growing a GaN nucleation layer, an unintentionally doped u-GaN layer, and an N-type doped GaN layer on a sapphire substrate;

[0024] Wherein, the growth temperature of the GaN nucleation layer is 550° C. to 680° C., and the thickness is 20 nm to 70 nm.

[0025] Wherein, the growth temperature of the unintentionally doped u-GaN layer is above 1100° C., and the thickness is 1 μm (micrometer) to 5 μm.

[0026] Herein, the range of A to B means within the range of A and B, and this range may include the two end values of A and B, or may not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com