Microcapsule embedding soybean source antioxidation peptide and preparation method thereof

A technology of antioxidant peptides and microcapsules, which is applied in protein food processing, plant protein processing, food science, etc., can solve the problems of no antioxidant activity, etc., and achieve the effect of feasible industrialization, simple process route, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

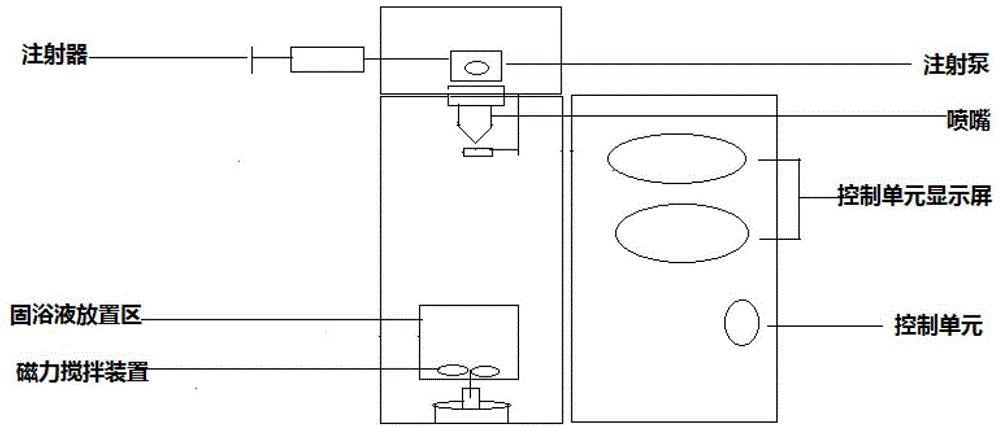

Image

Examples

Embodiment 1

[0032] Using soybean protein powder with a protein content of 40% as raw material, weigh a certain amount, dissolve it in water, prepare a solution with a protein concentration of 2%, adjust the speed of the high-speed homogenizer to 1500r / min, homogenize for 10min, and then transfer the solution to In an enzymolysis device with a stirring device, heat to 85°C, keep for 25min, then cool to 30°C, adjust the pH value to 9.50 with 1mol / L NaOH solution, add solid alkaline protease with a protein mass of 2%, the enzyme ratio The activity unit is 200,000 U / g, and the enzymatic hydrolysis is 5 hours. During the enzymatic hydrolysis, 1mol / L NaOH solution is continuously added dropwise to maintain the pH value of the solution during the enzymatic hydrolysis. The range of pH is 9.50±0.05; ℃, keep it for 10min, cool to 6℃, adjust the speed of the centrifuge to 0.8×10 4 Centrifuge at r / min, take the supernatant, adjust the pH value of the supernatant to 7.00±0.05 with 10mol / L HCl; adjust ...

Embodiment 2

[0034] Using soybean protein powder with a protein content of 60% as raw material, weigh a certain amount, dissolve it in water, prepare a solution with a protein concentration of 2%, adjust the speed of the high-speed homogenizer to 500r / min, homogenize for 15min, and then transfer the solution to In an enzymolysis device with a stirring device, heat to 90°C, keep for 10 minutes, then cool to 60°C, adjust the pH value to 11.50 with 10mol / L NaOH solution, add solid alkaline protease with a protein mass of 8%, the enzyme ratio The activity unit is 800,000 U / g, and the enzymatic hydrolysis is 3 hours. During the enzymatic hydrolysis, 10mol / L NaOH solution is continuously added dropwise to maintain the pH value of the solution during the enzymatic hydrolysis. The range of pH is 11.50±0.05; ℃, keep it for 10min, cool to 4℃, adjust the speed of the centrifuge to 0.9×10 4 Centrifuge at r / min, take the supernatant, adjust the pH value of the supernatant to 7.00±0.05 with 1mol / L HCl; ...

Embodiment 3

[0036] Using soybean protein powder with a protein content of 50% as raw material, weigh a certain amount, dissolve it in water, prepare a solution with a protein concentration of 6%, adjust the speed of the high-speed homogenizer to 600r / min, homogenize for 14min, and then transfer the solution to In the enzymolysis device with a stirring device, heat to 86°C, keep for 20min, then cool to 50°C, adjust the pH value to 10.50 with 6mol / L NaOH solution, add solid alkaline protease with a protein mass of 14%, the enzyme ratio The activity unit is 500,000 U / g, and the enzymatic hydrolysis is 2 hours. During the enzymatic hydrolysis, 6mol / L NaOH solution is continuously added dropwise to maintain the pH value of the solution during the enzymatic hydrolysis. The range of pH is 10.50±0.05; ℃, keep it for 10min, cool to 2℃, adjust the speed of the centrifuge to 1×10 4 Centrifuge at r / min, take the supernatant, adjust the pH value of the supernatant to 7.00±0.05 with 4mol / L HCl; adjust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com