Gel property modifier of frozen surimi product, and application thereof

A technology of frozen surimi and improver, which is applied in the field of food processing, can solve the problems of masking the flavor of surimi products, poor taste of vegetable juice, unstable quality, etc., and achieve delicate taste and water retention, good market competitiveness and application Foreground, the effect of solving rough taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

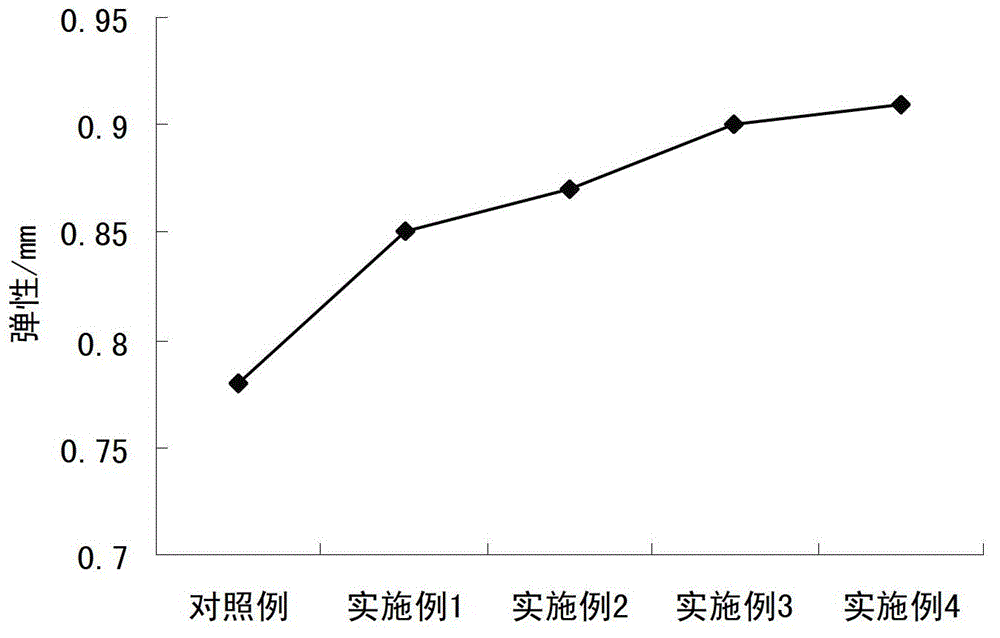

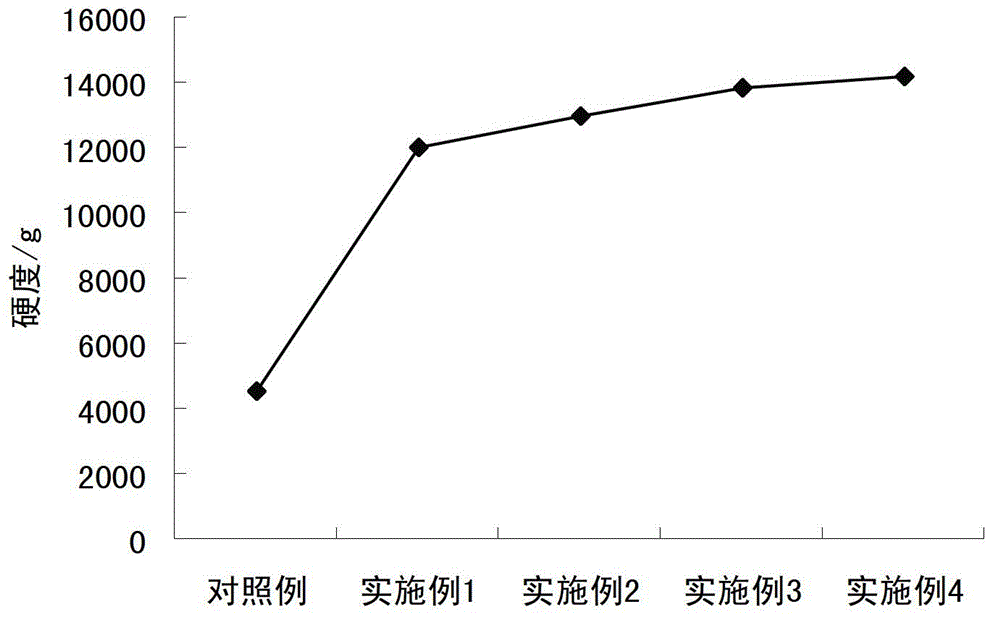

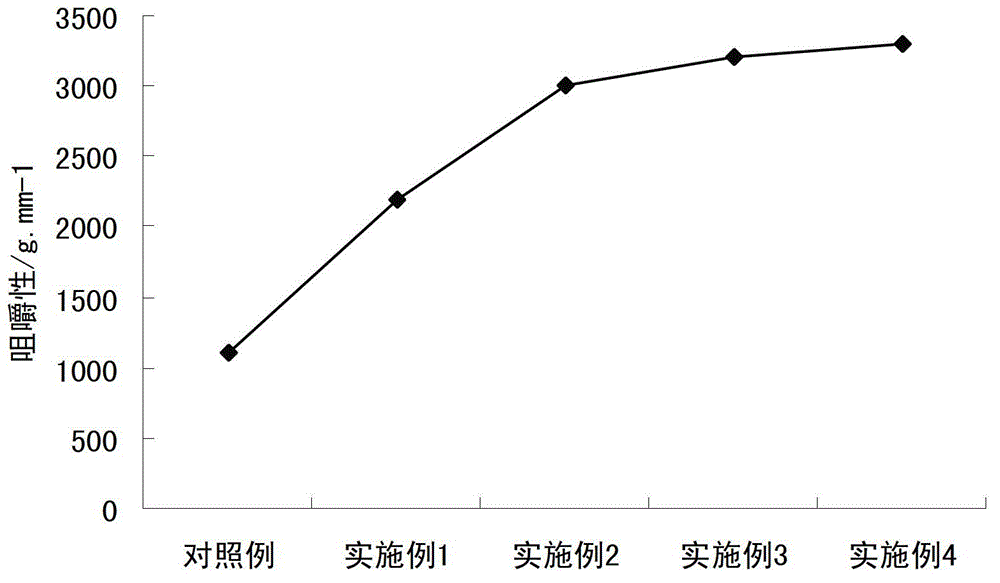

Embodiment 1

[0063] The frozen seaweed fish balls were made by adopting the above process. The silver carp is dehydrated and micronized surimi after raw material treatment, rinsing, fine filtration, refinement treatment and dehydration. The crushing process of dehydrated and micronized surimi starts with empty beating. Put the dehydrated and micronized surimi into a mortar and crush for 5 minutes. Based on the quality of the dehydrated and micronized surimi, add 0.5% salt for salting. Knead for 10 minutes, and finally mix for seasoning, add 0.2% γ-polyglutamic acid, 0.5% papain, 5% hydroxypropylated tapioca modified starch, and 0.1% seaweed powder, monosodium glutamate, sugar and cooking wine for seasoning The auxiliary materials (MSG: sugar: cooking wine = 30:6:1) continue to beat for 10 minutes. The crushed surimi meat is made into fish balls with a fish ball shaping machine, and then boiled, cooled, quick-frozen, frozen, packaged and other processes are made into frozen seaweed fish ba...

Embodiment 2

[0065] The frozen seaweed fish balls were made by adopting the above process. The silver carp is dehydrated and micronized surimi after raw material treatment, rinsing, fine filtration, refinement treatment and dehydration. The crushing process of dehydrated and micronized surimi starts with empty beating, puts the dehydrated and micronized surimi into a mortar and crushes for 5 minutes, and then puts 1% of salt into the process based on the quality of the dehydrated and micronized surimi. Salt milling for 11 minutes, and finally seasoning milling, 0.4% γ-polyglutamic acid, 0.8% papain, 10% hydroxypropylated tapioca modified starch, 0.2% seaweed powder, monosodium glutamate, sugar and cooking wine and other seasoning accessories (MSG: sugar: cooking wine = 30:6:1) Put it into the minced fish meat and continue to beat for 11 minutes. The crushed surimi meat is made into fish balls with a fish ball shaping machine, and then boiled, cooled, quick-frozen, frozen, packaged and oth...

Embodiment 3

[0067] The frozen seaweed fish balls were made by adopting the above process. The silver carp is dehydrated and micronized surimi after raw material treatment, rinsing, fine filtration, refinement treatment and dehydration. The crushing process of dehydrated and micronized surimi, first of all, empty beating, put the dehydrated and micronized surimi in a mortar and crush for 6 minutes, based on the quality of dehydrated and micronized surimi, then add 1.2% salt for Salt milling for 10 minutes, and finally seasoning milling, 0.6% γ-polyglutamic acid, 1.2% papain, 15% hydroxypropylated tapioca modified starch, 0.5% seaweed powder, monosodium glutamate, sugar and cooking wine and other seasoning accessories (MSG: sugar: cooking wine = 30:6:1) Put it into the minced fish meat and continue to beat for 13 minutes. The crushed surimi meat is made into fish balls with a fish ball shaping machine, and then boiled, cooled, quick-frozen, frozen, packaged and other processes are made int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com