Controllable short-process preparation method of nano titanium dioxide

A nano-titanium dioxide, short-process technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of time-consuming, difficult to clean, long preparation cycle, etc., to achieve high utilization rate and controllable synthesis process , the effect of short synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing nanometer titanium dioxide with a controllable short process, which is carried out according to the following steps:

[0025] (1) Under stirring conditions, add butyl titanate to the hydrogen peroxide solution in the water bath for reaction, the amount of butyl titanate added is according to Ti:H 2 o 2 The molar ratio is 1:2, the water bath temperature is 15°C, and the reaction time is 120min, a light orange gel is formed;

[0026] (2) Add an equal volume of deionized water to the light orange gel, heat and reflux to obtain a precipitate, centrifuge, and dry below 120°C to obtain white (sometimes slightly yellow) nanometer titanium dioxide powder.

[0027] The mass percent concentration of hydrogen peroxide is 3.5%.

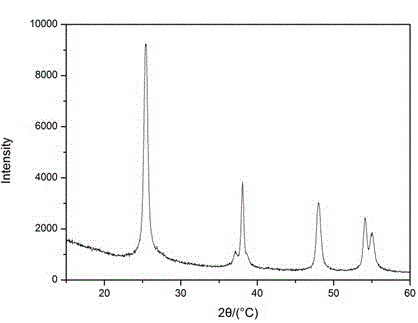

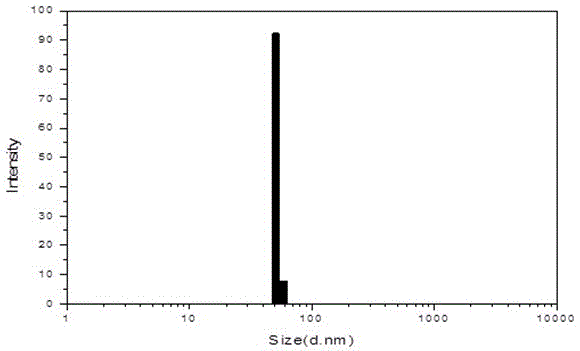

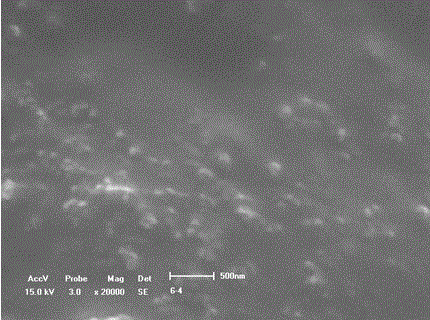

[0028] X-ray diffraction analysis of nano-titanium dioxide powder shows that the powder is anatase carbon dioxide, such as figure 1 Shown; Laser particle size analysis shows that the powder is 45-60 nanometers, and the maximum par...

Embodiment 2

[0030] A method for preparing nanometer titanium dioxide with a controllable short process, which is carried out according to the following steps:

[0031] (1) Under stirring conditions, add butyl titanate to the hydrogen peroxide solution in the water bath for reaction, the amount of butyl titanate added is according to Ti:H 2 o 2 The molar ratio is 1:5, the temperature of the water bath is 5°C, the reaction time is 198min, and a light orange gel is formed;

[0032] (2) Add an equal volume of deionized water to the light orange gel, heat and reflux to obtain a precipitate, centrifuge, and dry below 120°C to obtain white (sometimes slightly yellow) nanometer titanium dioxide powder.

[0033] The mass percent concentration of hydrogen peroxide is 6%.

[0034] X-ray diffraction analysis of nano-titanium dioxide powder shows that the powder is anatase carbon dioxide; laser particle size analysis shows that the powder is 45-60 nanometers, and the maximum particle size percentage...

Embodiment 3

[0036] A method for preparing nanometer titanium dioxide with a controllable short process, which is carried out according to the following steps:

[0037] (1) Under stirring conditions, add butyl titanate to the hydrogen peroxide solution in the water bath for reaction, the amount of butyl titanate added is according to Ti:H 2 o 2 The molar ratio is 1:15, the temperature of the water bath is 0°C, and the reaction time is 450min, a light orange gel is formed;

[0038] (2) Add an equal volume of deionized water to the light orange gel, heat to reflux to obtain a precipitate, centrifuge, and bake at 300°C for 120 minutes to obtain white (sometimes slightly yellow) nano-titanium dioxide powder.

[0039] The mass percent concentration of hydrogen peroxide is 5%.

[0040] X-ray diffraction analysis of nano-titanium dioxide powder shows that the powder is anatase carbon dioxide, as shown in the figure; laser particle size analysis shows that the powder is 45-60 nanometers, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com