Method for recovering vanadium from waste FCC catalyst

A catalyst and conversion technology, applied in the direction of vanadium oxide, etc., can solve the problems of vanadium that has not been reported in the literature, and achieve the effect of low environmental pollution and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

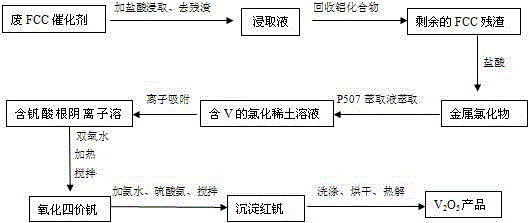

[0018] The present invention provides a kind of method that reclaims vanadium from spent FCC catalyst, further illustrate technical scheme of the present invention through specific implementation below:

[0019] A method for reclaiming vanadium from spent FCC catalysts, characterized in that: the method comprises the following steps:

[0020] Step 1: Add hydrochloric acid to the FCC catalyst for leaching to remove solid residues, and the metal elements contained in it are converted into hydrochloric acid double salt leaching solution. The leaching temperature is 60°C, the leaching time is 6 hours, the concentration of hydrochloric acid is 3mol / L, and the liquid-solid ratio is 6:1;

[0021] Step 2: reclaim the aluminum compound in the leaching solution;

[0022] Step 3: The remaining FCC residue is acidified with hydrochloric acid and converted into metal chlorides, extracted with P507 extract, and nickel is separated. 2.0mol / L, kerosene as diluent;

[0023] Step 4: Select 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com