Method for continuously producing 3-methyl-3-butylene-1-alcohol

A butene and methyl technology, applied in organic chemistry, oxygen-containing functional group reduction preparation, etc., can solve the problems of unstable quality, high reaction pressure, and many side reactions, and achieve high heat and mass transfer efficiency and mild reaction conditions. , the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

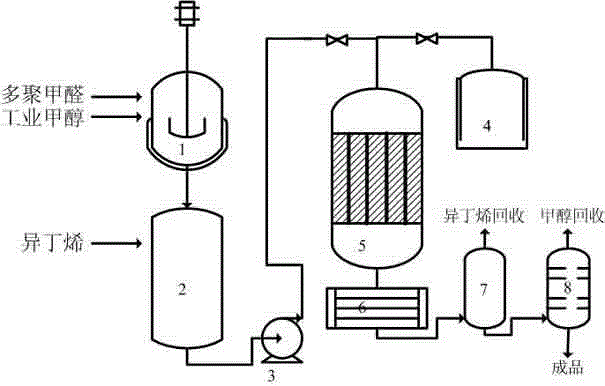

[0024] use figure 1 The shown continuous reaction device carries out the following operation process. Add 100kg of paraformaldehyde and 380L of industrial methanol to the stirring tank 1 (the purity of industrial methanol is: 98%, the converted molar ratio of paraformaldehyde and methanol is: 1:2.8), heat to 50°C under stirring, and continue stirring 2h until the paraformaldehyde is completely dissolved, then the paraformaldehyde solution and isobutylene are fed into the raw material bottle 2 at a volume ratio of 8.6:1 (the converted molar ratio of paraformaldehyde and isobutylene is 1:6.5), and then the raw material Fill the bottle 2 with nitrogen to 0.7MPa, and use the advection pump 3 to the tubular fixed bed reactor 4 at a space velocity of 1h -1 Continuously feed into the reactor 5, maintain the reaction temperature at 230°C, the reaction pressure at 8.5MPa, and continue to react for 25 hours. After the material is reacted in the tubular fixed bed reactor 4, it is cooled...

Embodiment 2

[0026] use figure 1 The shown continuous reaction device carries out the following operation process. Add 50kg of paraformaldehyde and 163L of industrial methanol to the stirring tank 1 (the purity of industrial methanol is: 98%, the converted molar ratio of paraformaldehyde and methanol is: 1:2.4), heat to 45°C while stirring, and continue stirring 2.5h until the paraformaldehyde is completely dissolved, then the paraformaldehyde solution and isobutylene are fed into the raw material bottle 2 at a volume ratio of 7.5:1 (the molar ratio of paraformaldehyde and isobutylene is converted to 1:7.6), and then Fill the raw material bottle 2 with nitrogen to 0.75MPa, and use the advection pump 3 to the tube-and-tube fixed-bed reactor 4 at a space velocity of 1.2h -1 Continuously feed into the reactor 5, maintain the reaction temperature at 240°C, the reaction pressure at 8.0MPa, and continue to react for 14 hours. After the material is reacted in the tubular fixed bed reactor 4, it ...

Embodiment 3

[0028] use figure 1 The shown continuous reaction device carries out the following operation process. Add 80kg of paraformaldehyde and 282L of industrial methanol to the stirred tank 1 (the purity of industrial methanol is: 98%, the converted molar ratio of paraformaldehyde and methanol is: 1:2.6), heat to 55°C while stirring, and continue stirring 2h until the paraformaldehyde is completely dissolved, then feed the paraformaldehyde solution and isobutylene into the raw material bottle 2 at a volume ratio of 8.0:1 (the converted molar ratio of paraformaldehyde to isobutylene is 1:7.0), and then feed the raw material Fill the bottle 2 with nitrogen to 0.8MPa, and use the advection pump 3 to the tube-and-tube fixed-bed reactor 4 at a space velocity of 1.8h -1 Continuously feed into the reactor 5, maintain the reaction temperature at 250°C, the reaction pressure at 9.0MPa, and continue to react for 18 hours. After the material is reacted in the tubular fixed bed reactor 4, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com