High-efficiency energy-saving preparation method and preparation device of acetylacetone

An acetylacetone, high-efficiency and energy-saving technology, applied in the field of chemical or pharmaceutical intermediate preparation, can solve the problems of high requirements on transfer equipment, insufficient process continuity, running, running, dripping, leaking, etc., to improve equipment utilization. , The effect of reducing the use of conveying equipment and reducing the amount of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

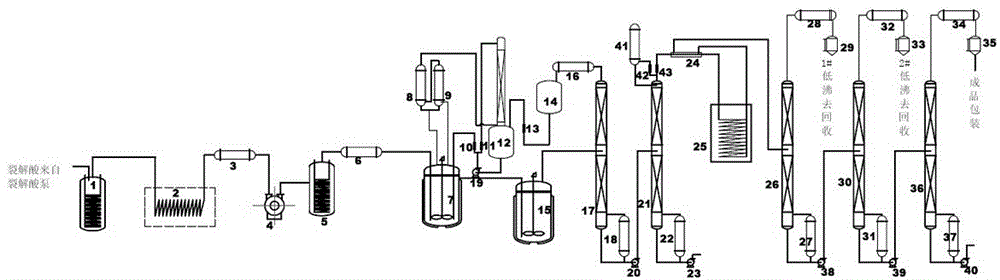

[0038] Schematic diagram of acetylacetone preparation device image 3 The pyrolysis acid comes from the pyrolysis acid pump, passes through the pyrolysis acid vaporizer 1, the pyrolysis gas cooler 2, and the vacuum pump 4, and then is separated by the oil anhydride separator 5 and then enters the pyrolysis gas recooler 6, to obtain the cracked ketene gas; The ketone gas is introduced into the absorption esterification tank 7, and the absorption esterification tank 7 is provided with an absorption primary condenser 9 and an absorption secondary condenser 8. The absorption esterification tank 7 is also connected with an acetone feeding flow meter 10 and an acetone spray flow meter 11 and acetone spray tower 12, acetone spray tower 12 and acetone feeding flow meter 10, acetone spray flow meter 11 is provided with an acetone spray pump 19 on the connecting pipe section, and one side of acetone spray tower 12 is connected with acetone inlet The material flow meter 13, the acetone fe...

Embodiment 1

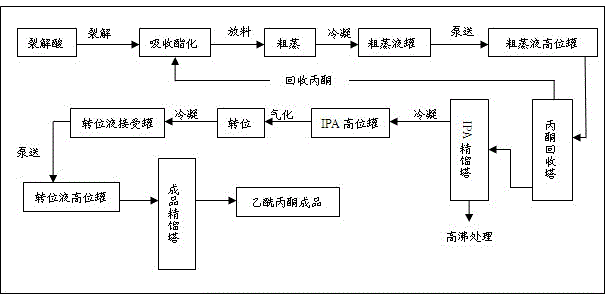

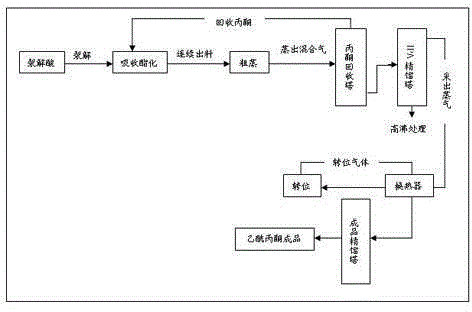

[0045] See the schematic diagram of the preparation process figure 2 .

[0046] First, 1000kg of acetone is added to the absorption esterification kettle, and then the pyrolysis acid is cracked at 700°C into ketene mixed gas and continuously passed into the absorption esterification kettle, and at the same time, acetone is continuously added at a rate of 120kg / hr.

[0047] Continuously lead the esterification liquid to the crude steamer through the overflow port, control the temperature of the crude steamer to 90℃, and continuously evaporate, so that the mixed gas continuously enters the acetone recovery tower, at the same time, open the reboiler steam of the acetone recovery tower, and control the temperature of the tower and kettle to 98± 2℃, after the reflux at the top of the tower, start to produce and recover acetone, control the temperature at the top of the tower to 54±2℃, and then turn on the acetone recovery tower kettle discharge pump to control the tower kettle liquid le...

example 2

[0050] First add 1000kg of acetone to the absorption esterification kettle, then the pyrolysis acid is cracked into ketene mixed gas at 750℃ to continuously pass into the absorption esterification kettle, at the same time, acetone is continuously added at the rate of 150kg / hr, and the esterification is continuously drawn through the overflow port Liquid to the crude steaming kettle, control the temperature of the crude steaming kettle to 90℃, continuously evaporate, make the mixed gas continuously enter the acetone recovery tower, and open the reboiler steam of the acetone recovery tower at the same time, control the temperature of the tower kettle to 98±2℃, and reflux at the top of the tower , Start to produce and recover acetone, control the temperature of the top of the tower to 54±2℃, then turn on the acetone recovery tower bottom discharge pump to control the level of the tower bottom to stabilize, and continuously feed the isopropenyl acetate distillation tower, and then tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com