Preparation method of TPO-L photoinitiator

A TPO-L, 1. TPO-L technology, applied in the field of TPO-L photoinitiator preparation, can solve the problems of complex production process, harsh reaction conditions and high equipment requirements, and achieve simple production process, fast curing speed, The effect of low production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

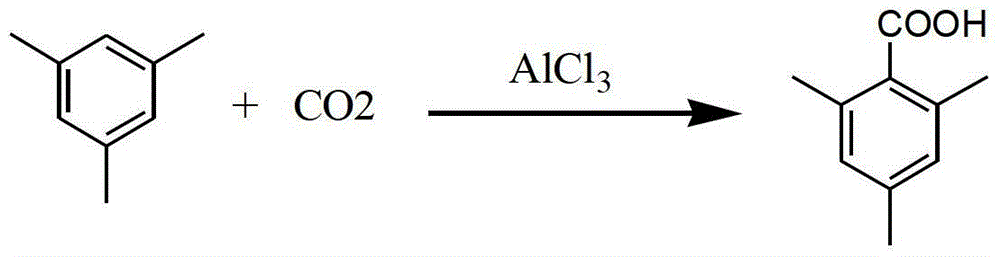

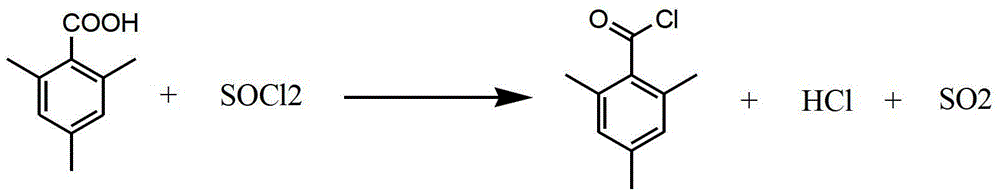

[0019] The preparation method of TPO-L photoinitiator includes 2,4,6-trimethylbenzoyl chloride preparation stage and TPO-L photoinitiator production stage, and the specific steps are as follows:

[0020] (1), 2,4,6-trimethylbenzoyl chloride preparation stage

[0021] First, put mesitylene 300kg, chlorobenzene 200kg, and aluminum trichloride 100kg into the alkylation reaction kettle by weight, stir and mix evenly, and maintain a certain pressure and flow of carbon dioxide into the reaction kettle. Synthesis of benzoic acid by radicalization, after the reaction is completed, the excess thionyl chloride is pumped in, and after substituted chlorination, atmospheric distillation is performed to recover the excess thionyl chloride and the solvent chlorobenzene, respectively. Color liquid 2,4,6-trimethylbenzoyl chloride;

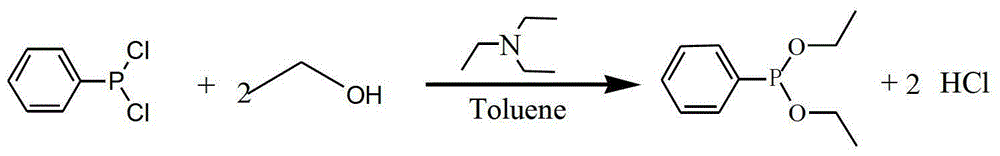

[0022] (2) Production stage of TPO-L photoinitiator

[0023] Put 50kg of toluene, 60kg of triethylamine and 80kg of anhydrous ethanol into the reaction kettle in...

Embodiment 2

[0027] The preparation method of TPO-L photoinitiator includes 2,4,6-trimethylbenzoyl chloride preparation stage and TPO-L photoinitiator production stage, and the specific steps are as follows:

[0028] (1), 2,4,6-trimethylbenzoyl chloride preparation stage

[0029] First, put mesitylene 400kg, chlorobenzene 250kg, and aluminum trichloride 200kg into the alkylation reaction kettle by weight, stir and mix evenly, and maintain a certain pressure and flow of carbon dioxide into the reaction kettle. Synthesis of benzoic acid by radicalization, after the reaction is completed, the excess thionyl chloride is pumped in, and after substituted chlorination, atmospheric distillation is performed to recover the excess thionyl chloride and the solvent chlorobenzene, respectively. Color liquid 2,4,6-trimethylbenzoyl chloride;

[0030] (2) Production stage of TPO-L photoinitiator

[0031] Put 75kg of toluene, 90kg of triethylamine and 90kg of anhydrous ethanol into the reaction kettle in...

Embodiment 3

[0034] The preparation method of TPO-L photoinitiator includes 2,4,6-trimethylbenzoyl chloride preparation stage and TPO-L photoinitiator production stage, and the specific steps are as follows:

[0035] (1), 2,4,6-trimethylbenzoyl chloride preparation stage

[0036] First, put mesitylene 500kg, chlorobenzene 300kg, and aluminum trichloride 300kg into the alkylation reaction kettle by weight, stir and mix evenly, and maintain a certain pressure and flow of carbon dioxide into the reaction kettle. Synthesis of benzoic acid by radicalization, after the reaction is completed, the excess thionyl chloride is pumped in, and after substituted chlorination, atmospheric distillation is performed to recover the excess thionyl chloride and the solvent chlorobenzene, respectively. Color liquid 2,4,6-trimethylbenzoyl chloride;

[0037] (2) Production stage of TPO-L photoinitiator

[0038] Put 100kg of toluene, 120kg of triethylamine and 100kg of anhydrous ethanol into the reaction kettle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com