Water-based semitransparent film-forming emulsion and preparation method thereof

A film-forming emulsion and translucent technology, applied in the field of ink, can solve the problems of dull color, poor compatibility and poor water resistance, and achieve the effect of high solid content, stable performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

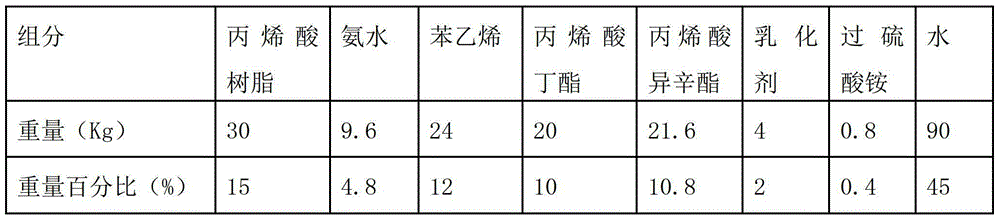

[0029] The formula of water-based translucent film-forming emulsion is composed of the following ingredients in proportion (total weight: 200Kg):

[0030]

[0031] The preparation method of above-mentioned translucent film-forming emulsion is as follows:

[0032] a. Add the above-mentioned acrylic resin, ammonia water and 88.6Kg of water into the reaction kettle, heat to 85°C, stir until the acrylic resin is dissolved, and keep it warm for 2 hours to obtain the first solution. The pH value of the first solution is 8.8;

[0033] b. Add the above-mentioned styrene, butyl acrylate, and isooctyl acrylate into the monomer high-level tank, and mix to obtain the second solution; add 1.1Kg of ammonium persulfate and 2.8Kg of water into the catalyst tank, and mix to obtain the third solution ;

[0034] c. Add the above-mentioned emulsifier to the first solution, stir and mix to obtain the fourth solution;

[0035] d. Add the second solution and the third solution dropwise to the f...

Embodiment 2

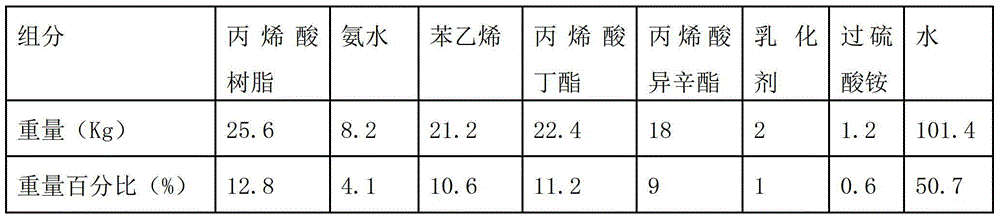

[0041] The formula of water-based translucent film-forming emulsion is composed of the following ingredients in proportion (total weight: 200Kg):

[0042]

[0043] Wherein, the concentration of ammonia water is 20%; Acrylic resin is made up of J678 acrylic resin and J67 acrylic resin, and the weight ratio of J678 acrylic resin and J67 acrylic resin is 3.5:1, and J67 acrylic resin is produced by U.S. BASF Corporation; Emulsifier is The X-45 produced by Weiberg, Germany.

[0044] The preparation method of above-mentioned translucent film-forming emulsion is as follows:

[0045] a. Add the above-mentioned acrylic resin, ammonia water and 86.9Kg of water into the reaction kettle, heat to 85°C, stir until the acrylic resin dissolves, and keep it warm for 1 hour to obtain the first solution, the pH of the first solution is 8.7;

[0046] b. Add the above-mentioned styrene, butyl acrylate, and isooctyl acrylate into the high tank of the monomer, and mix to obtain the second soluti...

Embodiment 3

[0054] The formula of water-based translucent film-forming emulsion is composed of the following ingredients in proportion (total weight: 200Kg):

[0055]

[0056] Wherein, the concentration of ammonia water is 22%; acrylic resin is made up of J678 acrylic resin and J67 acrylic resin, and the weight ratio of J678 acrylic resin and J67 acrylic resin is 4:1, and J67 acrylic resin is produced by U.S. BASF; emulsifier is The X-45 produced by Weiberg, Germany.

[0057] The preparation method of above-mentioned translucent film-forming emulsion is as follows:

[0058]a. Add the above-mentioned acrylic resin, ammonia water and 97.3Kg of water into the reaction kettle, heat to 88°C, stir until the acrylic resin dissolves, and keep warm for 1.5h to obtain the first solution, the pH of the first solution is 8.4;

[0059] b. Add the above-mentioned styrene, butyl acrylate, and isooctyl acrylate into the monomer high-level tank, and mix to obtain the second solution; add 1.12Kg of amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com