Modified intumescent flame-retardant polypropylene composition and preparation method thereof

A polypropylene composition and an intumescent flame retardant technology are applied in the fields of nano-zinc oxide modified intumescent flame retardant polypropylene composition and preparation thereof, modified intumescent flame retardant polypropylene composition and preparation thereof, polypropylene composition field, It can solve the problems of decreased mechanical properties, poor dispersion and poor compatibility, and achieve the effects of improving mechanical properties, improving flame retardant efficiency and excellent flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

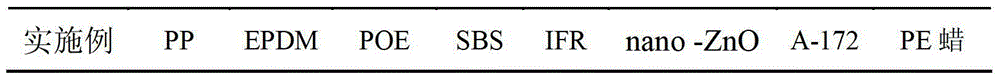

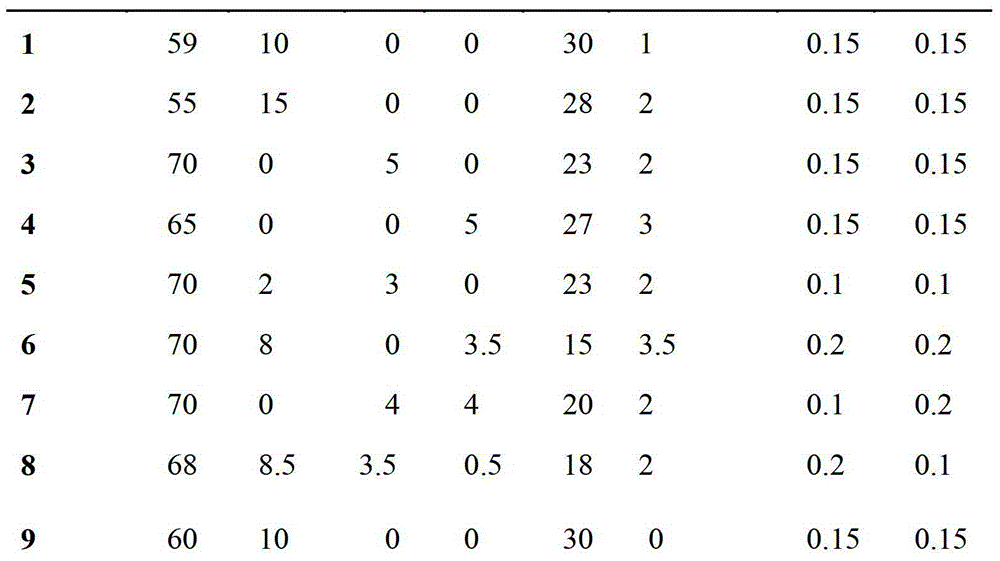

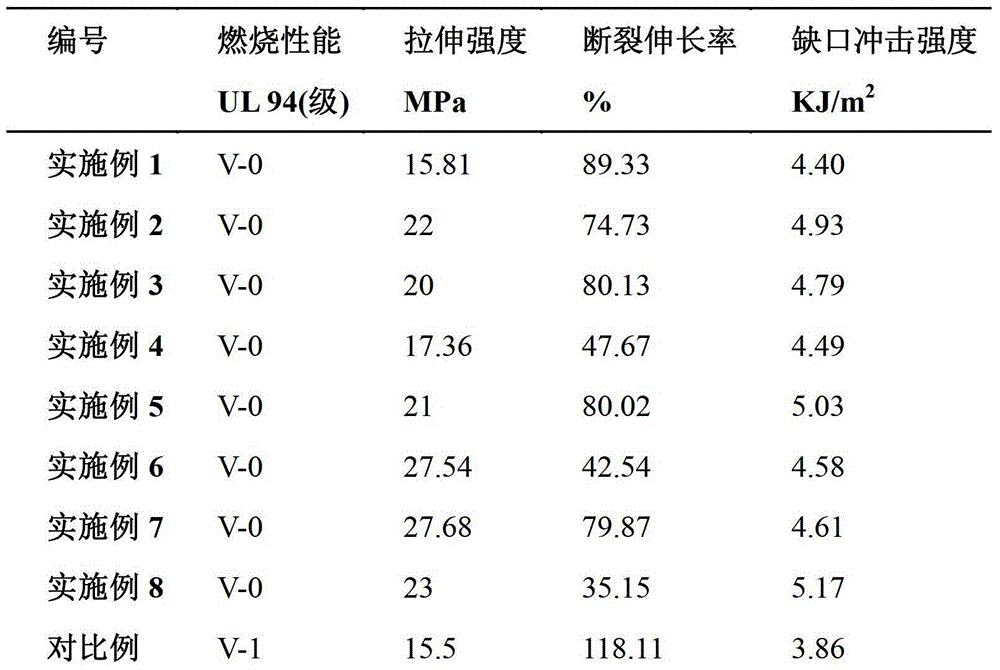

[0026] In terms of parts by mass, each raw material was weighed as shown in Table 1 for Examples 1-8. Example 9 in Table 1 is a comparative example. The toughening agent is one or more of ethylene propylene diene monomer (EPDM), ethylene octene copolymer (POE) or styrene butadiene block copolymer (SBS). The compound intumescent flame retardant (IFR) is composed of high ammonium polyphosphate (APP), dipentaerythritol (DPER), and melamine (MEL) in a mass ratio of 40-60:10-15:15-20; among them, high Ammonium polyphosphate is selected from type II ammonium polyphosphate with a high degree of polymerization, and the degree of polymerization n>100; the purity of melamine is analytically pure; when preparing, firstly mix high ammonium polyphosphate (APP), dipentaerythritol (DPER) and melamine (MEL) Prepare an intumescent flame retardant (IFR) in proportion, dry in an oven at 90-110°C for 5-10 hours, and set aside; then mix nano-ZnO (nano-ZnO), compound intumescent flame retardant (I...

Embodiment 1

[0030] The preparation method of embodiment 1

[0031] A preparation method of a modified expanded flame-retardant polypropylene composition, comprising the steps of:

[0032] (1) Prepare APP, DPER and MEL in proportion to make intumescent flame retardant IFR, dry in an oven at 100°C for 5 hours, and set aside.

[0033] (2) Weigh nano-ZnO, IFR, A-172, and PE wax according to the ratio in Table 1 and put them into a high-speed mixer (GH100Y, produced by Beijing Plastic Machinery Factory) and mix them for 20 minutes to obtain surface modification. Composite flame retardant IFR / nano-ZnO.

[0034] (3) Add the modified IFR / nano-ZnO, PP, and EPDM into a high-speed mixer (GH100Y, produced by Beijing Plastic Machinery Factory) according to the ratio in Table 1, and then use a three-screw extruder to extrude and make pellets to obtain modified expanded flame-retardant polypropylene composition pellets. The three-screw extruder is divided into a solid conveying zone, a solid-solution ...

Embodiment 2

[0035] The preparation method of embodiment 2

[0036] A preparation method of a modified expanded flame-retardant polypropylene composition, comprising the steps of:

[0037](1) Prepare APP, DPER and MEL in proportion to make intumescent flame retardant IFR, dry in an oven at 100°C for 5 hours, and set aside.

[0038] (2) Weigh nano-ZnO, IFR, A-172, and PE wax according to the ratio in Table 1 and put them into a high-speed mixer (GH100Y, produced by Beijing Plastic Machinery Factory) and mix them for 20 minutes to obtain surface modification. Composite flame retardant IFR / nano-ZnO.

[0039] (3) Add the modified IFR / nano-ZnO, PP, and EPDM into a high-speed mixer (GH100Y, produced by Beijing Plastic Machinery Factory) according to the ratio in Table 1, and then use a three-screw extruder to extrude and make pellets to obtain modified expanded flame-retardant polypropylene composition pellets. The three-screw extruder is divided into a solid conveying zone, a solid-solution m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com