Ethylene-vinyl acetate copolymer adhesive film and preparation method thereof

A technology of vinyl acetate and copolymer, which is applied in the field of ethylene-vinyl acetate copolymer film and its manufacture, can solve problems such as limiting the synergistic effect of acidic substances, and achieve excellent long-term UV aging resistance, avoid negative effects, and excellent durability The effect of heat and humidity aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The proportion of raw materials in this specific embodiment is based on the following parts by weight.

[0067] 100 parts of ethylene-vinyl acetate copolymer, wherein: the vinyl acetate content in the ethylene-vinyl acetate copolymer is 25%;

[0068] Cross-linking agent: 0.1 part of 1,1-bis(tert-butylperoxide)-3,3,5-trimethylcyclohexane;

[0069] Co-crosslinking agent: 0.1 part of trimethylolpropane trimethacrylate;

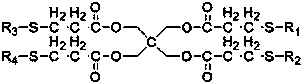

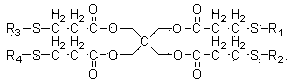

[0070] Antioxidant (thiopropionate): 0.1 part of pentaerythritol tetrakis (3-octylthiopropionate);

[0071] Ultraviolet light absorber: 0.5 part of 2-hydroxy-4-n-octyloxybenzophenone;

[0072] Light stabilizer: 0.5 part of a polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidinol;

[0073] Tackifier: 0.1 part of γ-methacryloyloxypropyltrimethoxysilane.

[0074] The ethylene-vinyl acetate copolymer adhesive film of this specific embodiment is manufactured by the following method:

[0075] Step 1: Add cross-linking agent, co-cross-linki...

Embodiment 2

[0079] The proportion of raw materials in this specific embodiment is based on the following parts by weight.

[0080] 100 parts of ethylene-vinyl acetate copolymer, and the vinyl acetate content in the ethylene-vinyl acetate copolymer is 33%;

[0081] Cross-linking agent: 1.0 part of 1,1-bis(tert-butylperoxide)-3,3,5-trimethylcyclohexane;

[0082] Co-crosslinking agent: 1.0 part of triallyl isocyanurate;

[0083] Antioxidant (thiopropionate): 0.5 part of pentaerythritol tetrakis (3-dodecyl thiopropionate);

[0084] Ultraviolet light absorber: 0.1 part of 2-hydroxy-4-n-octyloxybenzophenone;

[0085] Light stabilizer: 0.05 part of bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate;

[0086] Tackifier: 0.5 part of γ-methacryloyloxypropyltrimethoxysilane.

[0087] The ethylene-vinyl acetate copolymer adhesive film of this specific embodiment is manufactured by the following method:

[0088] Step 1: Add cross-linking agent, co-cross-linking agent, tackifier, and ultraviolet li...

Embodiment 3

[0092] The proportion of raw materials in this specific embodiment is based on the following parts by weight.

[0093] 100 parts of ethylene-vinyl acetate copolymer, and the vinyl acetate content in the ethylene-vinyl acetate copolymer is 28%;

[0094] Cross-linking agent: 0.5 part of tert-butyl peroxide-2-ethylhexyl carbonate;

[0095] Co-crosslinking agent: 0.5 part of triallyl isocyanurate;

[0096] Antioxidant (thiopropionate): 0.25 part of pentaerythritol tetrakis (3-decyl thiopropionate);

[0097] Ultraviolet light absorber: 0.25 part of 2-hydroxy-4-n-octyloxybenzophenone;

[0098] Light stabilizer: 0.25 part of bis(1-octyloxy-2,2,6,6-tetramethyl-4-piperidinyl) sebacate;

[0099] Tackifier: 0.25 part of γ-methacryloyloxypropyltrimethoxysilane.

[0100] The ethylene-vinyl acetate copolymer adhesive film of this specific embodiment is manufactured by the following method:

[0101] Step 1: Add cross-linking agent, co-cross-linking agent, tackifier, and ultraviolet ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com