Novel leaching process of extracting precious metals such as gold, silver and the like from silver separating residues

A precious metal and silver slag separation technology, which is applied in the field of precious metal leaching and extraction technology, can solve the problems of difficulty in recycling, inability to effectively comprehensively recover precious metals and valuable metals, and increase the burden of anode slime treatment procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

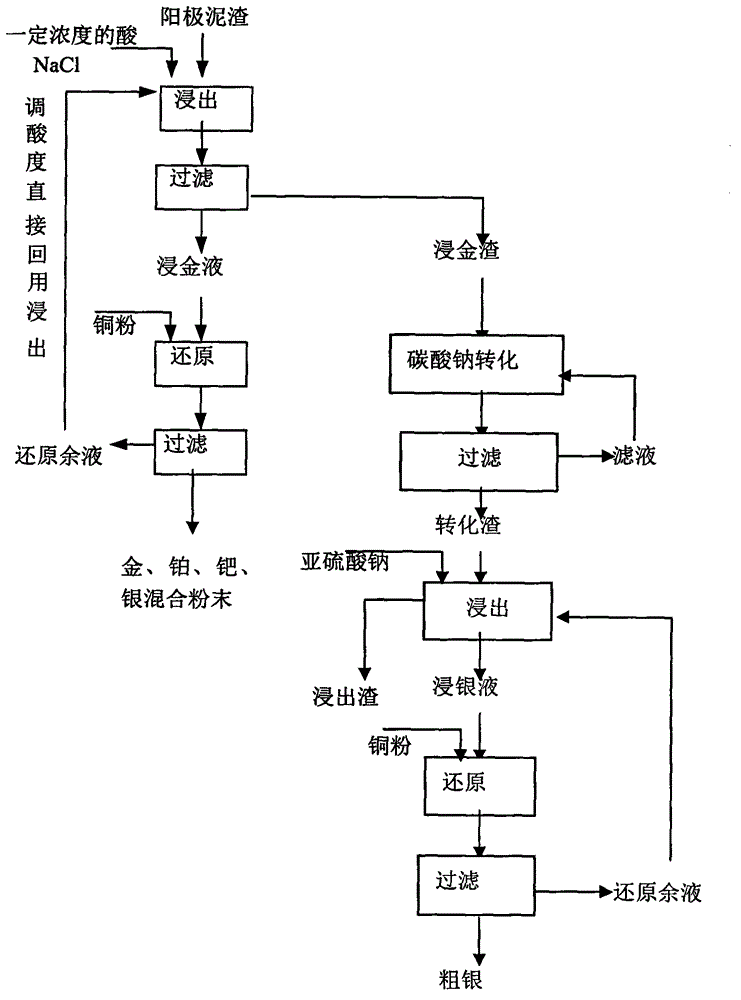

Image

Examples

example 1

[0017] Put 140g of chlorinated silver slag into 800ml of 3mol / L hydrochloric acid, add 10g of sodium chloride, heat for 2h, and most of the gold in the silver slag is transferred to the solution. Cool and filter to obtain about 100g of leaching residue and 800ml of leaching solution. The gold leaching rate is about 98.5%. Add 1g of pure copper powder to the leaching solution, react for 4 hours, and filter to obtain 1.45g of precious metal powder. The leached residue was added to 1000ml of 0.2mol / L sodium carbonate solution, and the conversion reaction was carried out at 40°C for 3h. After cooling and filtering, the filtrate is converted and reused next time, and the leached residue is added to 500ml of 2mol / L sodium sulfite solution, heated and stirred for 3 hours. Cool and filter to obtain about 96.5g of filter residue that can be used for lead-antimony smelting, add 5g of pure copper powder to 500ml of silver leaching solution, react for 4h, and filter to obtain 6.3g of mixe...

example 2

[0019] Put 140g of chlorinated silver slag into 800ml of 6mol / L hydrochloric acid, add 10g of sodium chloride, heat for 2h, and most of the gold in the silver slag is transferred to the solution. Cool and filter to obtain about 95g of leaching residue and 800ml of leaching solution. The gold leaching rate is about 98.5%. Add 1g of pure copper powder to the leaching solution, react for 4 hours, and filter to obtain 1.52g of precious metal powder. The leached residue was added to 1000ml of 0.2mol / L sodium carbonate solution, and the conversion reaction was carried out at 40°C for 3h. After cooling and filtering, the filtrate is converted and reused next time, and the leached residue is added to 500ml of 2mol / L sodium sulfite solution, heated and stirred for 3 hours. Cool and filter to obtain about 96.5g of filter residue that can be used for lead-antimony smelting, add 5g of pure copper powder to 500ml of silver immersion solution, react for 4h, and filter to obtain 6.15g of mix...

example 3

[0021] Put 140g of chlorinated silver slag into 800ml of 2.5mol / L sulfuric acid, add 30g of sodium chloride, heat for 4h, and most of the gold in the silver slag is transferred to the solution. Cool and filter to obtain about 106g of leaching residue and 800ml of leaching solution. The gold leaching rate is about 98.1%. Add 1g of pure copper powder to the leaching solution, react for 4 hours, and filter to obtain 1.45g of precious metal powder. The leached residue was added to 1000ml of 0.2mol / L sodium carbonate solution, and the conversion reaction was carried out at 40°C for 3h. After cooling and filtering, the filtrate is converted and reused next time, and the leached residue is added to 500ml of 2mol / L sodium sulfite solution, heated and stirred for 3 hours. Cool and filter to obtain about 96.5g of filter residue that can be used for lead-antimony smelting, add 5g of pure copper powder to 500ml of silver leaching solution, react for 4 hours, and filter to obtain 6.35g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com