Chemical copper-plating activating process of ceramic material

A ceramic material, chemical copper plating technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of difficult to achieve complete coverage, complex colloidal solution preparation, poor coating adhesion, etc. The effect of bonding force and coverage, saving precious metal resources, and good wrapping property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

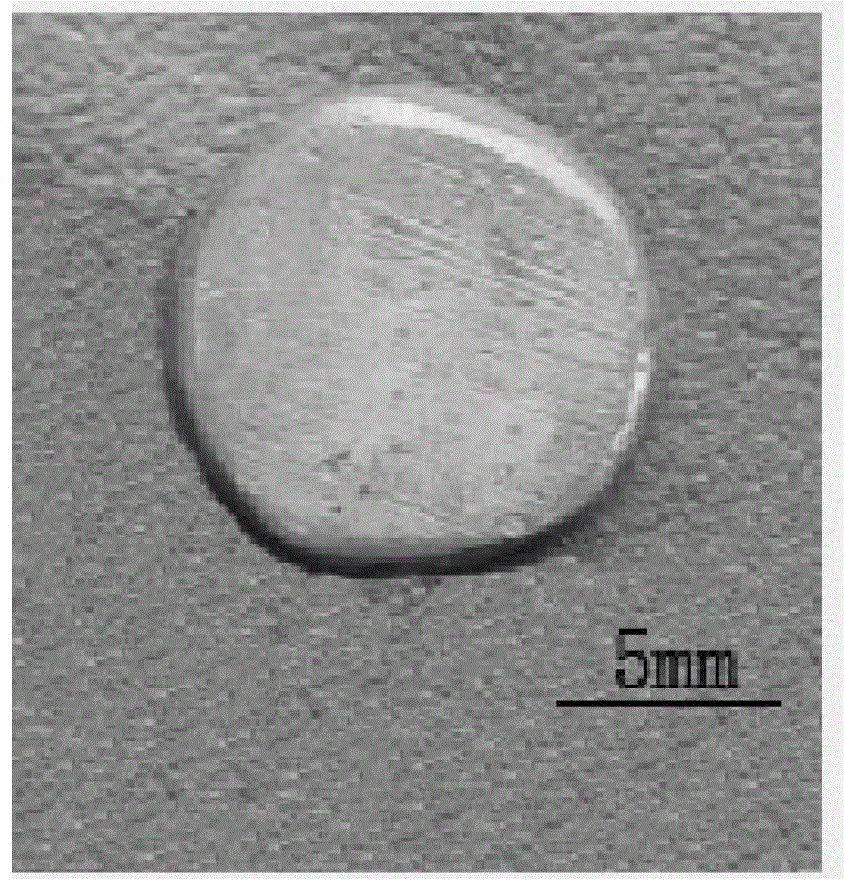

[0018] Soak the ceramic substrate in a degreasing solution at 50°C for 10 minutes, take it out and wash it with water at 55°C, and then wash it with running water; then put the cleaned ceramic substrate in a roughening solution at 35°C for 4 minutes After roughening, it was washed with ultrasonic water for 15 minutes; then it was taken out and dried, put into the activation solution for immersion at room temperature for 30 minutes, and after taking it out, it was thermally reduced in a box furnace at 135°C for 50 minutes to obtain the activated ceramic matrix.

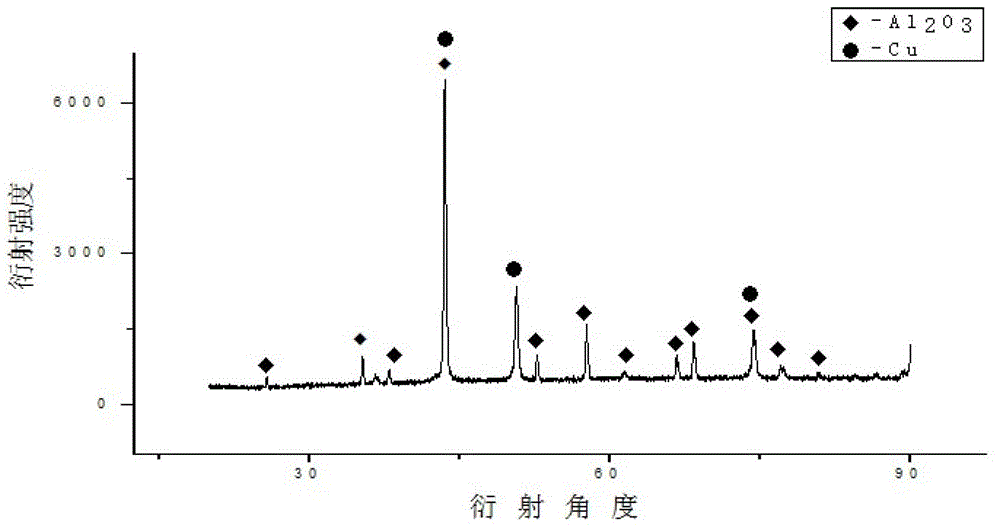

[0019] Wherein, the degreasing solution is made up of OP emulsifier, NaOH and water, and the concentration of OP emulsifier is 2-3g / L, and the concentration of NaOH is 5-10g / L; Composed of 98% sulfuric acid and water, and the concentration of sodium thiosulfate is 200-220g / L, the concentration of sulfuric acid is 15-35ml / L; the activation solution is made of CuSO 4 、NiSO 4 , NaH 2 PO 4 and water, and CuSO 4 The con...

Embodiment 2

[0021] Soak the ceramic substrate in a 50°C degreasing solution for 10 minutes, take it out and wash it with 55°C water first, and then wash it with running water; then put the cleaned ceramic substrate into a 35°C roughening solution for 4 minutes, After roughening, wash with ultrasonic water for 15 minutes; then take it out and dry it, put it into the activation solution for immersion at room temperature for 30 minutes, take it out and heat reduction treatment in a box furnace at 135°C for 50 minutes to obtain the activated ceramic matrix.

[0022] Among them, the degreasing solution is composed of OP emulsifier, NaOH and water, and the concentration of OP emulsifier is 2-3g / L, and the concentration of NaOH is 5-10g / L; the roughening solution is composed of sodium thiosulfate, mass concentration It is composed of 98% sulfuric acid and water, and the concentration of sodium thiosulfate is 200-220g / L, the concentration of sulfuric acid is 15-35ml / L; the activation solution is m...

Embodiment 3

[0024] Soak the ceramic substrate in a degreasing solution at 50°C for 10 minutes, take it out and wash it with water at 55°C, and then wash it with running water; then put the cleaned ceramic substrate in a roughening solution at 35°C for 4 minutes After roughening, it was washed with ultrasonic water for 15 minutes; it was taken out and dried, and then immersed in the activation solution at room temperature for 30 minutes. After taking it out, it was thermally reduced in a box furnace at 135°C for 55 minutes to obtain an activated ceramic matrix.

[0025] Wherein, the degreasing solution is made up of OP emulsifier, NaOH and water, and the concentration of OP emulsifier is 2-3g / L, and the concentration of NaOH is 5-10g / L; Composed of 98% sulfuric acid and water, and the concentration of sodium thiosulfate is 200-220g / L, the concentration of sulfuric acid is 15-35ml / L; the activation solution is made of CuSO 4 、NiSO 4 , NaH 2 PO 4 and water, and CuSO 4 The concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com