Method for preparing nano-silver-graphene composite film

A graphene composite and nano-silver technology, applied in solid-state chemical plating, metal material coating process, coating, etc., can solve the problems of high cost, inability to prepare large sizes, and restrict application range, etc., to achieve excellent Raman enhancement effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Firstly, the graphene oxide was prepared into a suspended aqueous solution with a concentration of 1 mg / mL and ultrasonically dispersed until it was uniformly dispersed, then 10 mL of silver nitrate aqueous solution with a concentration of 0.029 mmol / mL was mixed with 50 mL of graphene oxide aqueous solution, and the silver nitrate solution was obtained after ultrasonic dispersion for 2 h. Ion-graphene oxide colloidal solution; take 10 mL silver ion-graphene oxide colloidal solution, use vacuum filtration process to obtain silver ion-graphene oxide composite film, put the film in a drying oven at 30°C for 1 h, and then remove it Filter the membrane, and place the obtained composite film in a tube furnace at 300 °C for 2 h in a hydrogen / argon (volume ratio 1:2) mixed gas to obtain a nano-silver-graphene composite film.

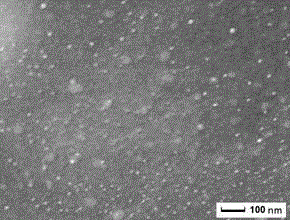

[0025] figure 1 For the SEM photo of the composite film, from figure 1 It can be seen in the figure that many nano-silver particles have been distribut...

Embodiment 2

[0027] Firstly, the graphene oxide was prepared into a suspended aqueous solution with a concentration of 1 mg / mL and ultrasonically dispersed until it was uniformly dispersed, then 10 mL of silver nitrate aqueous solution with a concentration of 0.029 mmol / mL was mixed with 50 mL of graphene oxide aqueous solution, and the silver nitrate solution was obtained after ultrasonic dispersion for 2 h. Ion-graphene oxide colloidal solution, take 10 mL silver ion-graphene oxide colloidal solution, use vacuum filtration process to obtain silver ion-graphene oxide composite film, put the film in a drying oven at 30 ° C for 1 h and remove Filtration membrane; the obtained composite film was placed in a tube furnace at 400 °C and heat-treated in a hydrogen / argon (volume ratio 1:2) mixed gas for 2 h to obtain a nano-silver-graphene composite film.

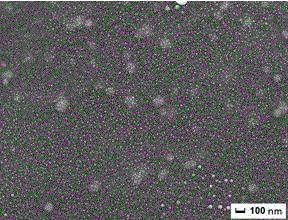

[0028] figure 2 For the SEM photo of the composite film, from figure 2 It can be seen that as the temperature rises to 400°C, the top of t...

Embodiment 3

[0030] Firstly, the graphene oxide was prepared into a suspended aqueous solution with a concentration of 1 mg / mL and ultrasonically dispersed until it was uniformly dispersed, then 10 mL of silver nitrate aqueous solution with a concentration of 0.029 mmol / mL was mixed with 50 mL of graphene oxide aqueous solution, and the silver nitrate solution was obtained after ultrasonic dispersion for 2 h. Ion-graphene oxide colloidal solution, take 10 mL silver ion-graphene oxide colloidal solution, use vacuum filtration process to obtain silver ion-graphene oxide composite film, put the film in a drying oven at 30 ° C for 1 h and remove The membrane was filtered, and the obtained composite film was placed in a tube furnace at 600 °C for 2 h in a hydrogen / argon (volume ratio 1:2) mixed gas to obtain a nano-silver-graphene composite film.

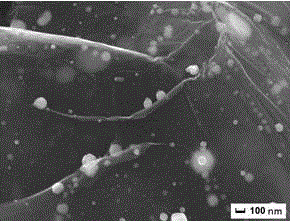

[0031] image 3 For the SEM photo of the composite film, from image 3 It can be seen that as the temperature rises to 600 °C, the morphology of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com