Non-inductive capacitor

A capacitor, non-inductive technology, applied in the direction of fixed capacitor terminal, fixed capacitor shell/package, fixed capacitor components, etc., can solve the problem of large contact resistance between the gold spray layer and the core, easy to interfere with the use of other components, and capacitor life. It can achieve the effect of excellent high-frequency performance, long service life and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings.

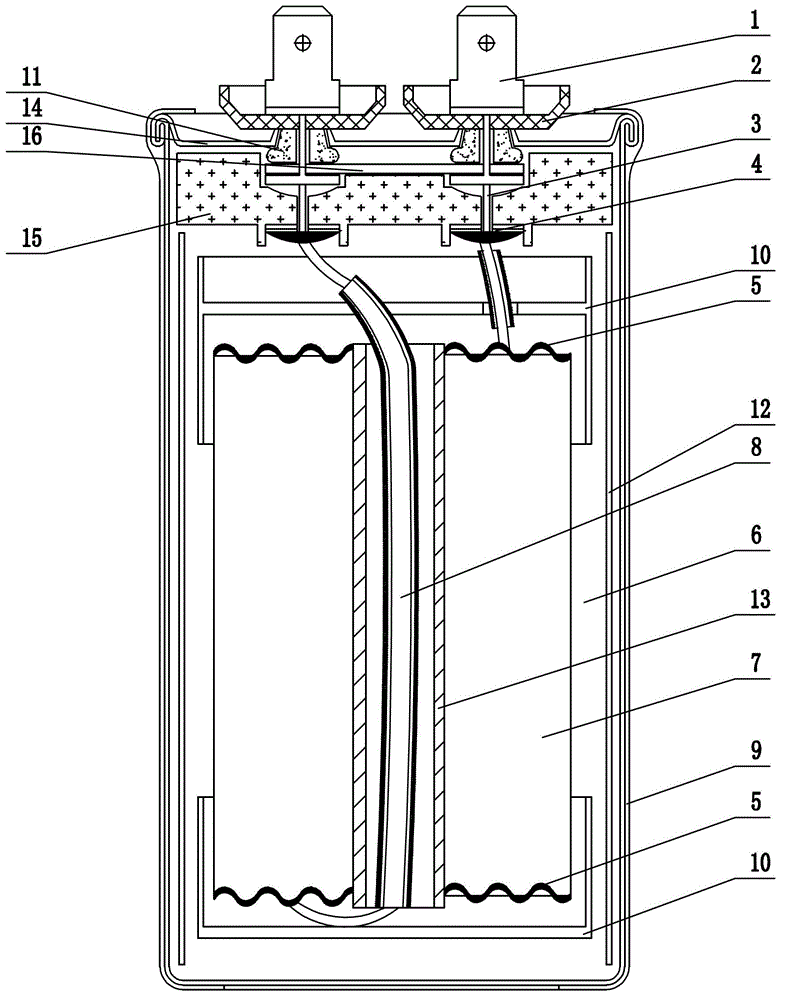

[0012] Such as figure 1 As shown: the non-inductive capacitor includes solder tab 1, plastic sheath 2, solid rivet 3, copper foil 4, zinc layer 5, filler 6, capacitive element 7, lead wire 8, aluminum shell 9, plastic sleeve 10, sealing ring 11. Film body 12, mandrel 13, explosion-proof end cap 14, explosion-proof plate 15, fixed bridge 16, etc.

[0013] Such as figure 1 As shown, the present invention comprises an aluminum casing 9 and a capacitive element 7 packaged in the aluminum casing 9, a thin film body 12 is provided between the aluminum casing 9 and the capacitive element 7, and a lead wire 8 is arranged in a mandrel 13 in the middle of the capacitive element 7 , the upper and lower ends of the capacitive element 7 are respectively provided with plastic sleeves 10; the upper end of the aluminum casing 9 is provided with an explosion-proof end cap 14, and the edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com