Instant edible compressed water shield and preparation method thereof

A technology of compressing water shield and compressing water shield, which is applied in the field of food technology, can solve the problems of water shield quality reduction, large consumption, and inconvenient storage and transportation, and achieve the effects of reducing the loss of nutrients, simple preparation steps, and convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of preparation method of compressed water shield

[0031]A preparation method of compressed water shield, specifically comprising the following steps:

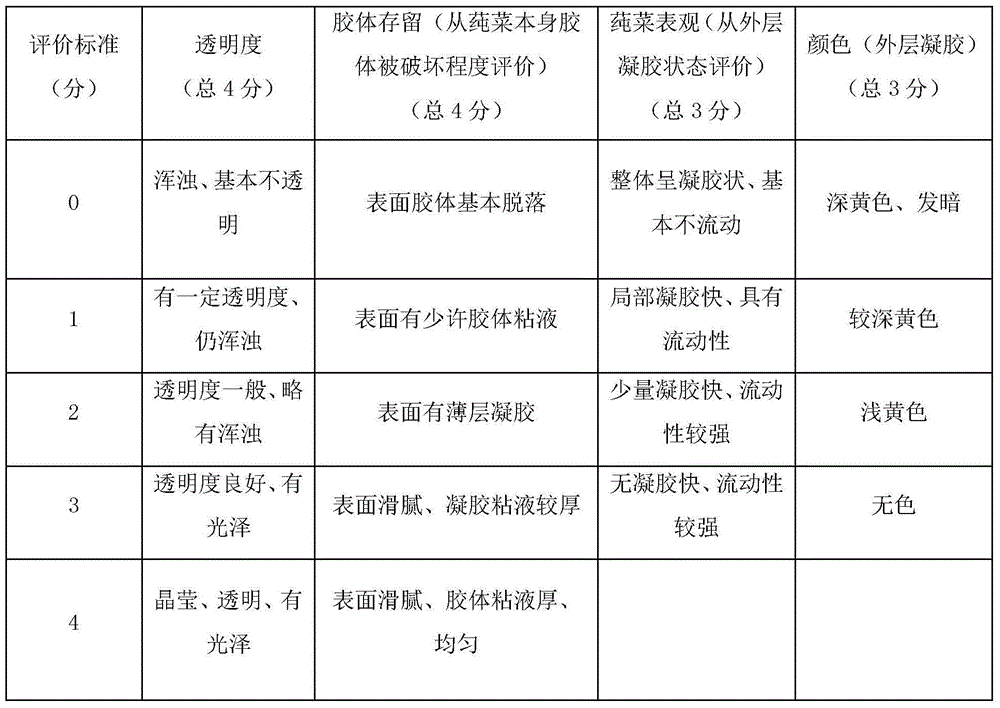

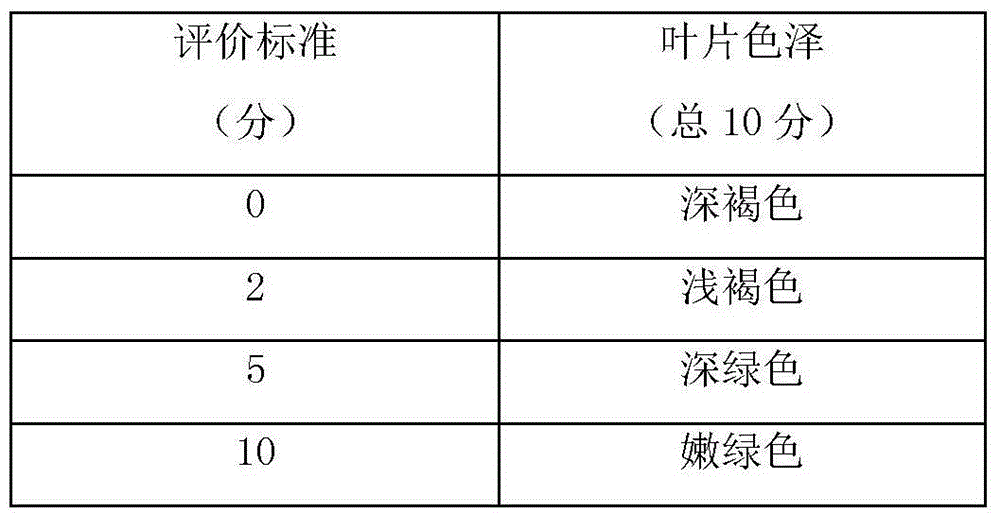

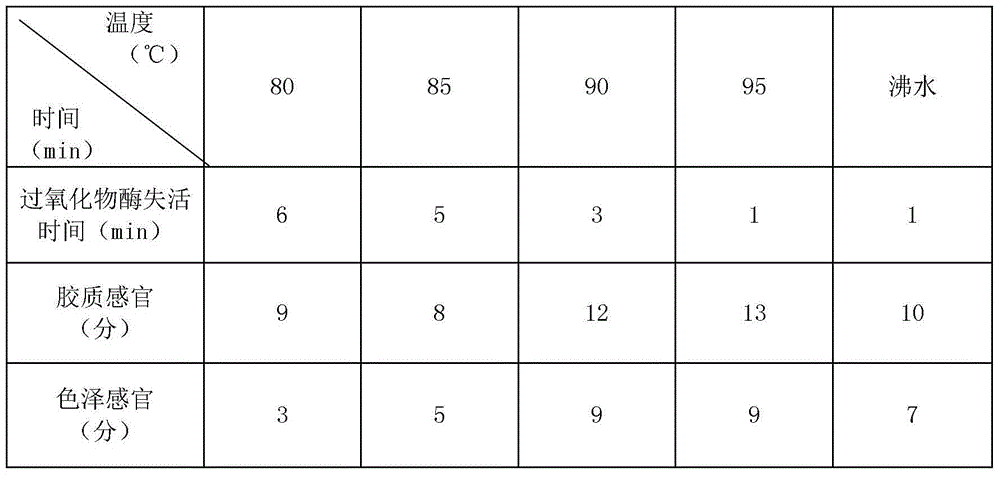

[0032] (1) Wash the collected fresh water shield and put it into water at a temperature of 90°C to blanch and fix it for 3 minutes to get green water shield;

[0033] (2) keeping the green water shield obtained in step (1) at a temperature of 100°C and a pressure of 130KPa for 30 minutes to obtain ripened water shield;

[0034] (3) Dry the cooked water shield obtained in step (2) until the water content is 20%, add seasonings, and compress at a temperature of 40°C and a pressure of 12MPa for 100s, that is, the water shield is shaped by hot pressing at a compression rate of 8 times compressed, and then dried until the water content is 10% to obtain compressed water shield products. The water shield compressed product can be packaged after being sterilized.

Embodiment 2

[0035] Embodiment 2 A kind of preparation method of compressed water shield

[0036] A preparation method of compressed water shield, specifically comprising the following steps:

[0037] (1) Clean the collected fresh water shield and put it into water at a temperature of 95°C to blanch and fix it for 2 minutes to get green water shield;

[0038] (2) The dehydrated water shield obtained in step (1) was centrifuged and dehydrated at 4000 rpm for 3 minutes to remove surface moisture to obtain dehydrated water shield;

[0039] (3) keeping the green water shield obtained in step (2) at a temperature of 100°C and a pressure of 130KPa for 12 minutes to obtain cooked water shield;

[0040] (4) Dry the cooked water shield obtained in step (3) until the water content is 30%. After adding seasonings, compress at a temperature of 55°C and a pressure of 12MPa for 100s, that is, the water shield is shaped by hot pressing at a compression rate of 10 times. Compress and dry it until the wa...

Embodiment 3

[0047] Embodiment 3 A kind of preparation method of water shield

[0048] A preparation method of compressed water shield, specifically comprising the following steps:

[0049] (1) Wash the collected fresh water shield and put it into water with a temperature of 95° C. to blanch and fix it for 1 minute to get green water shield;

[0050] (2) dehydrating water shield obtained in step (1) by centrifugal dehydration at 3500°C for 5 minutes to remove surface moisture to obtain dehydrated water shield;

[0051] (3) keeping the dehydrated water shield obtained in step (2) at a temperature of 95° C. and a pressure of 100 KPa for 15 minutes to obtain ripened water shield;

[0052] (4) Dry the ripened water shield obtained in step (3) until the water content is 40%. After adding the seasoning, compress for 120s at a temperature of 60°C and a pressure of 10 MPa, that is, the water shield is shaped by hot pressing at a compression rate of 15 times. compressed, and then dried to a moist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com